Detection device and detection method for detecting absence of trolley fire grate bar

A detection device and grate technology are applied in the detection device and detection field for detecting the lack of grate bars of a trolley, which can solve problems such as unfavorable process energy consumption, flue gas and dust emission cost, etc., and achieve favorable current consumption and flow rate. Maintain stability and facilitate the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

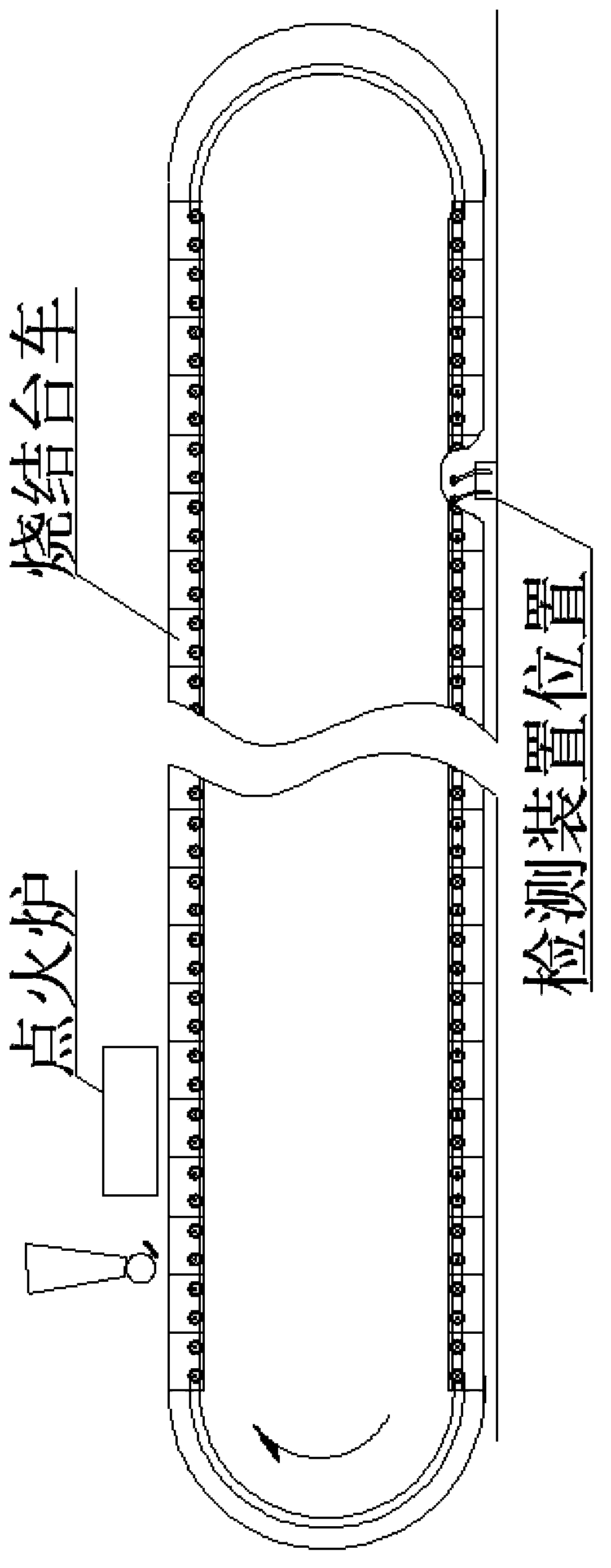

[0041] like figure 2 As shown, the grate bars on the sintering trolley all have a fixed number, so as to realize the close arrangement of each other. When more than two grating bars are missing due to wear, it will cause loosening between the original tightly arranged grating bars, which often causes the sintering trolley to turn over from the upper track to the lower track, and the lower track to the upper track. When on the ring track, the grate bar will further drop due to loss of support on the trolley. Therefore, this technology detects the sintering trolley running on the lower ring track in advance, so as to avoid the trolley missing the grate bar from repeatedly turning over.

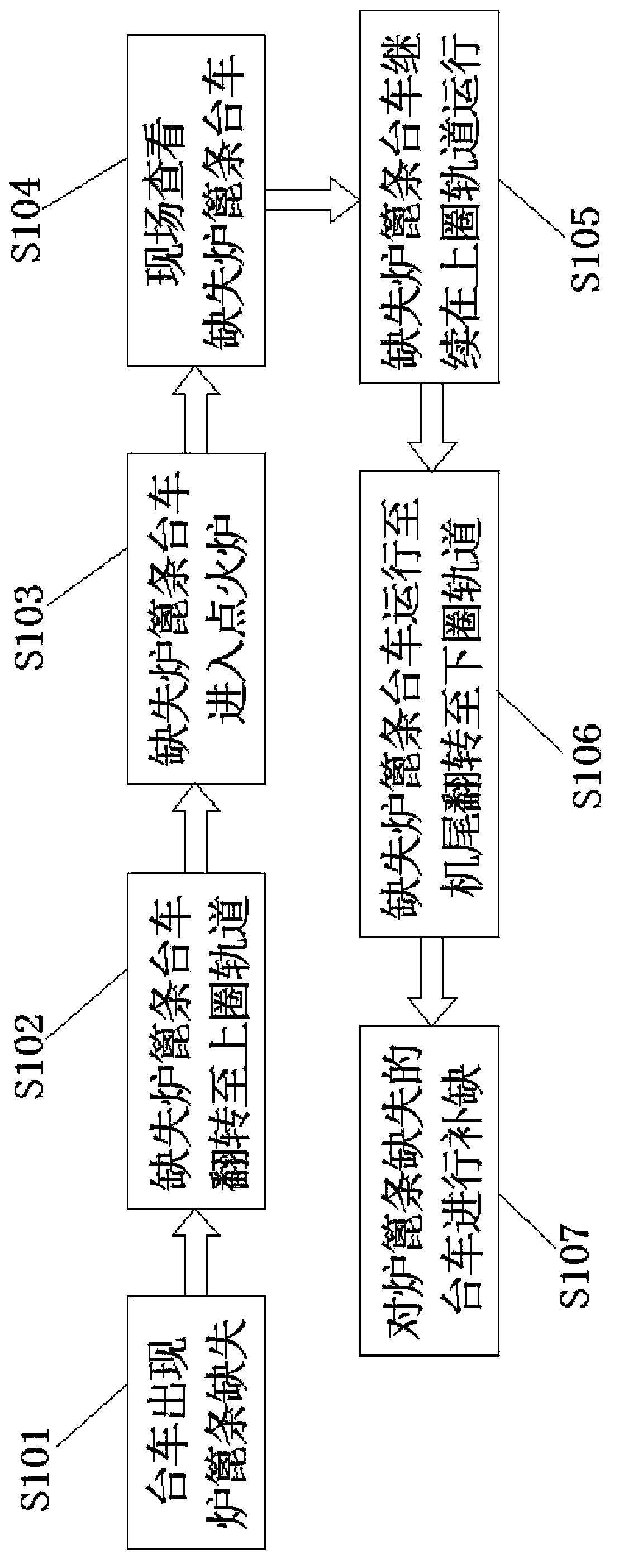

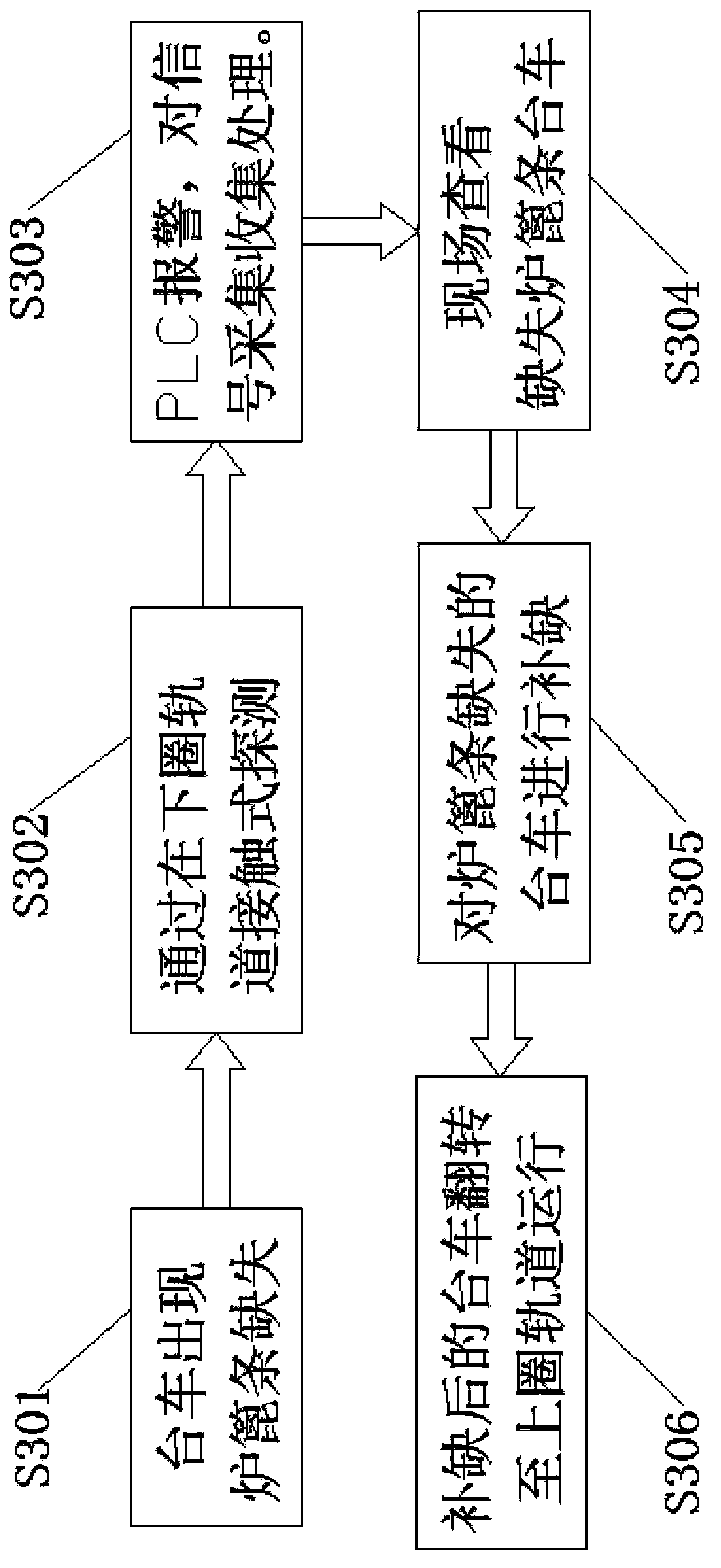

[0042] like image 3 Shown, detection method of the present invention is, utilizes the feature that the plane formed when the grate bar 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com