Test device for linear motion module

A technology of testing equipment and motion modules, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as unreliable accuracy, unstable force application, and inability to measure mechanical efficiency, and achieve easy digitization, large accuracy drop, and The effect of a large margin of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

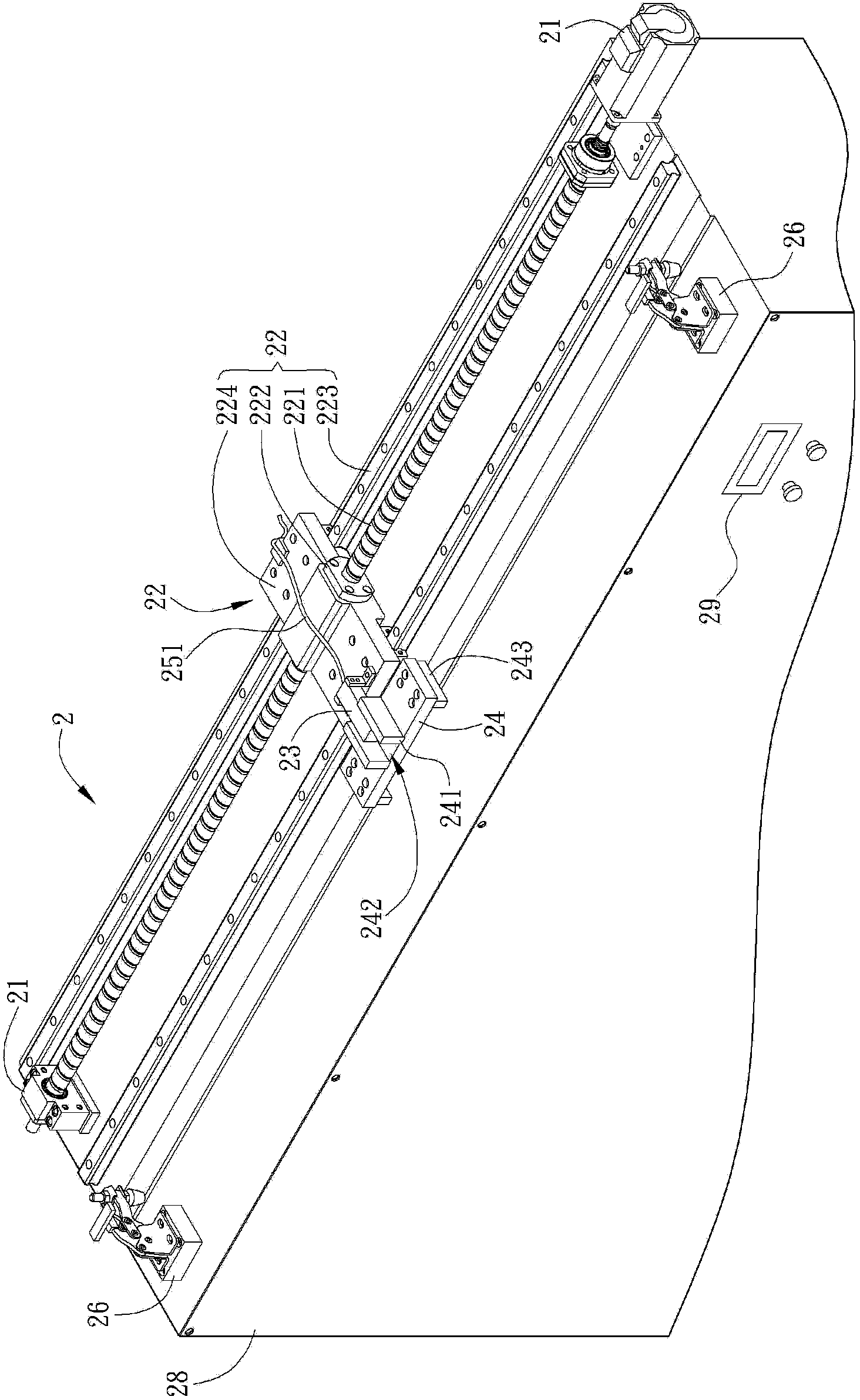

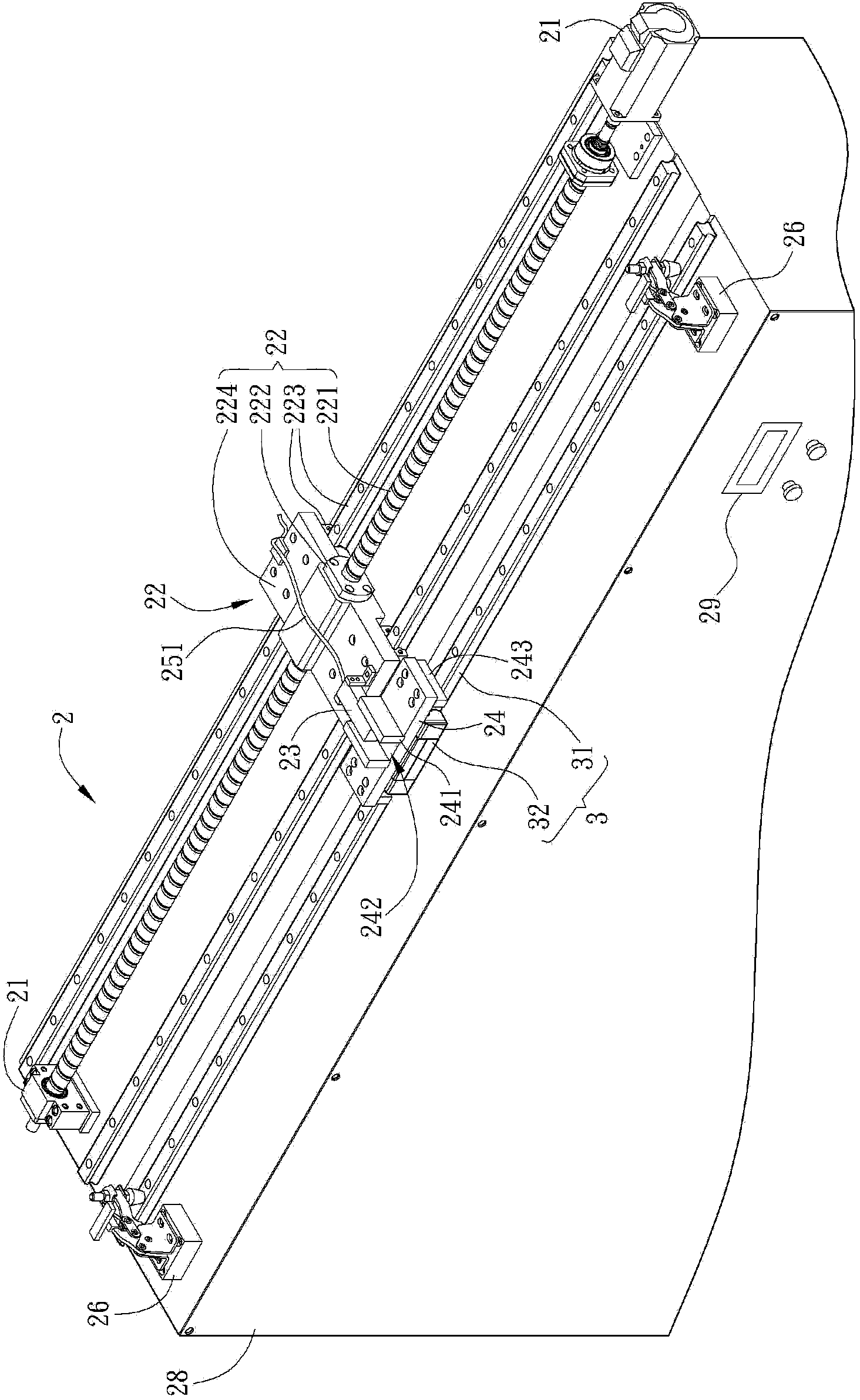

[0061] A testing device for a linear motion module according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference numerals.

[0062] figure 2 It is a schematic diagram of a testing device for a linear motion module according to the present invention, image 3 for figure 2 A schematic diagram of the test equipment and linear motion module shown, Figure 4 for figure 2 An exploded schematic of the test equipment is shown. The following first cooperate Figure 2 to Figure 4Explain the structure and components of the test equipment, and then further use to specify the relevant details.

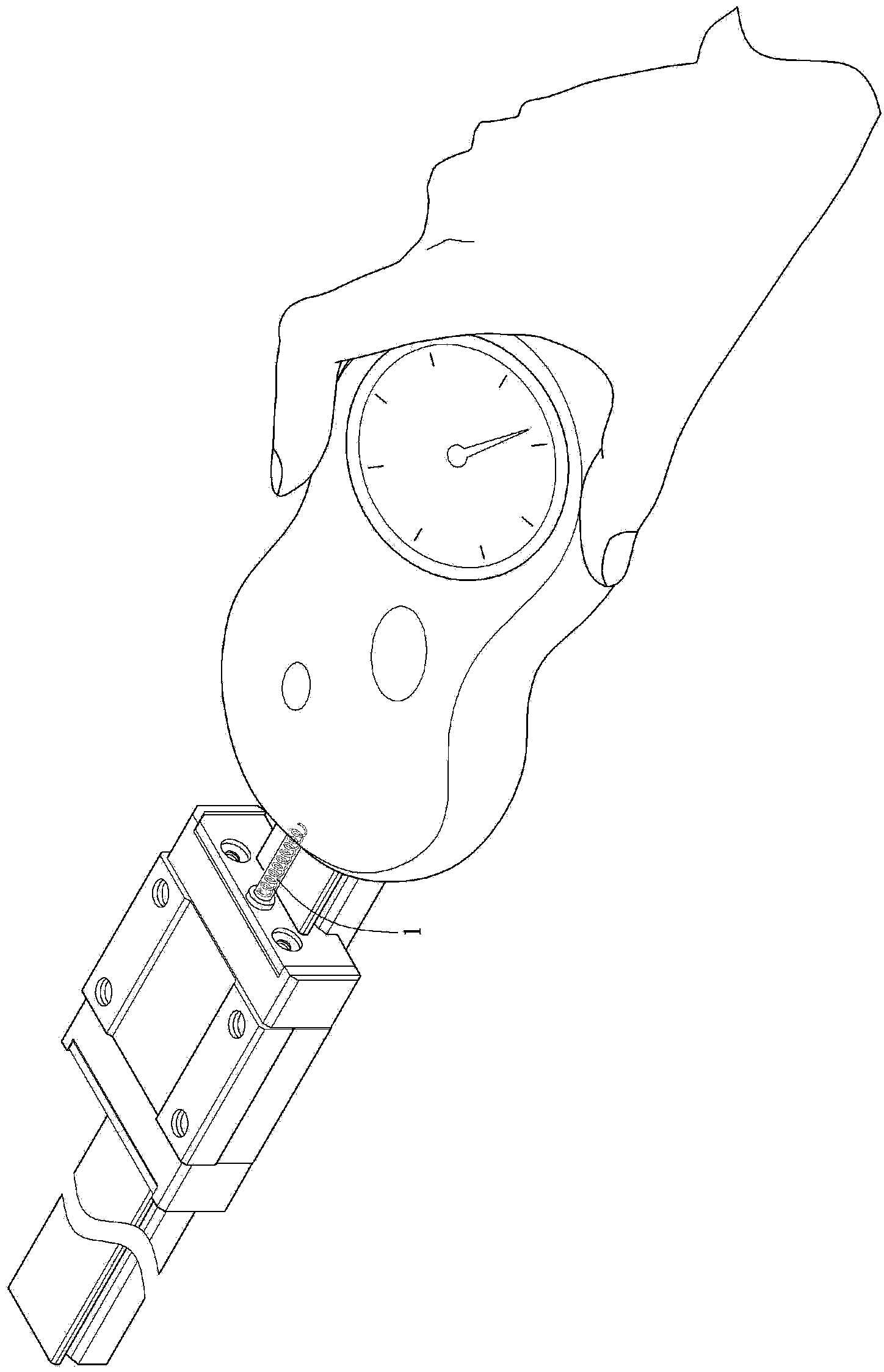

[0063] Please also refer to figure 2 and image 3 As shown, the testing device 2 of the present invention is used to test a linear motion module 3 . The linear motion module 3 to be tested can be any linear slide rail or linear guide rail, and has a linear tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com