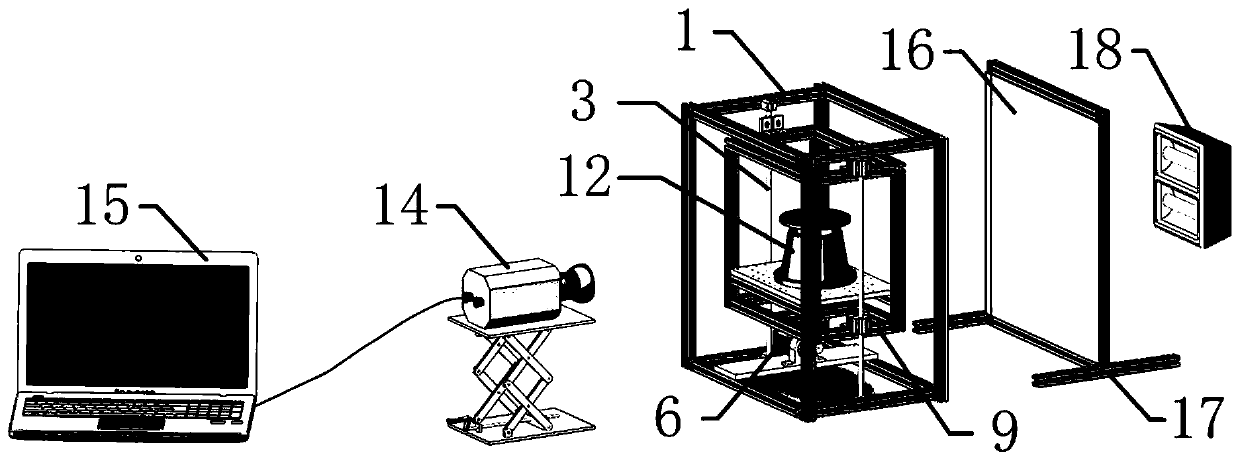

Low-frequency vibration isolation test bench and vibration detecting system

A test bench and vibration isolation technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of harsh use conditions and high prices, and achieve the effect of strong applicability, taking into account functions and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

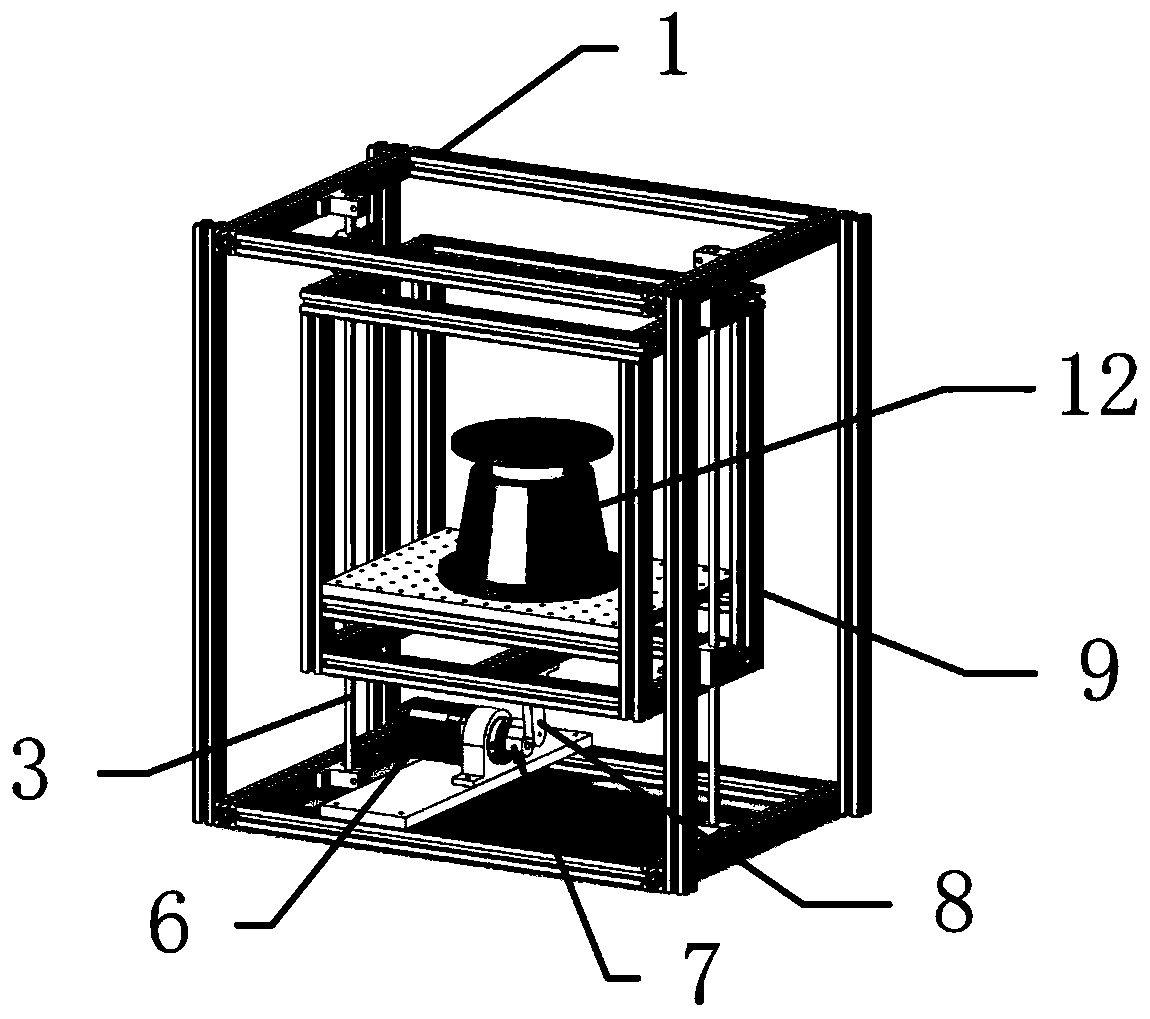

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

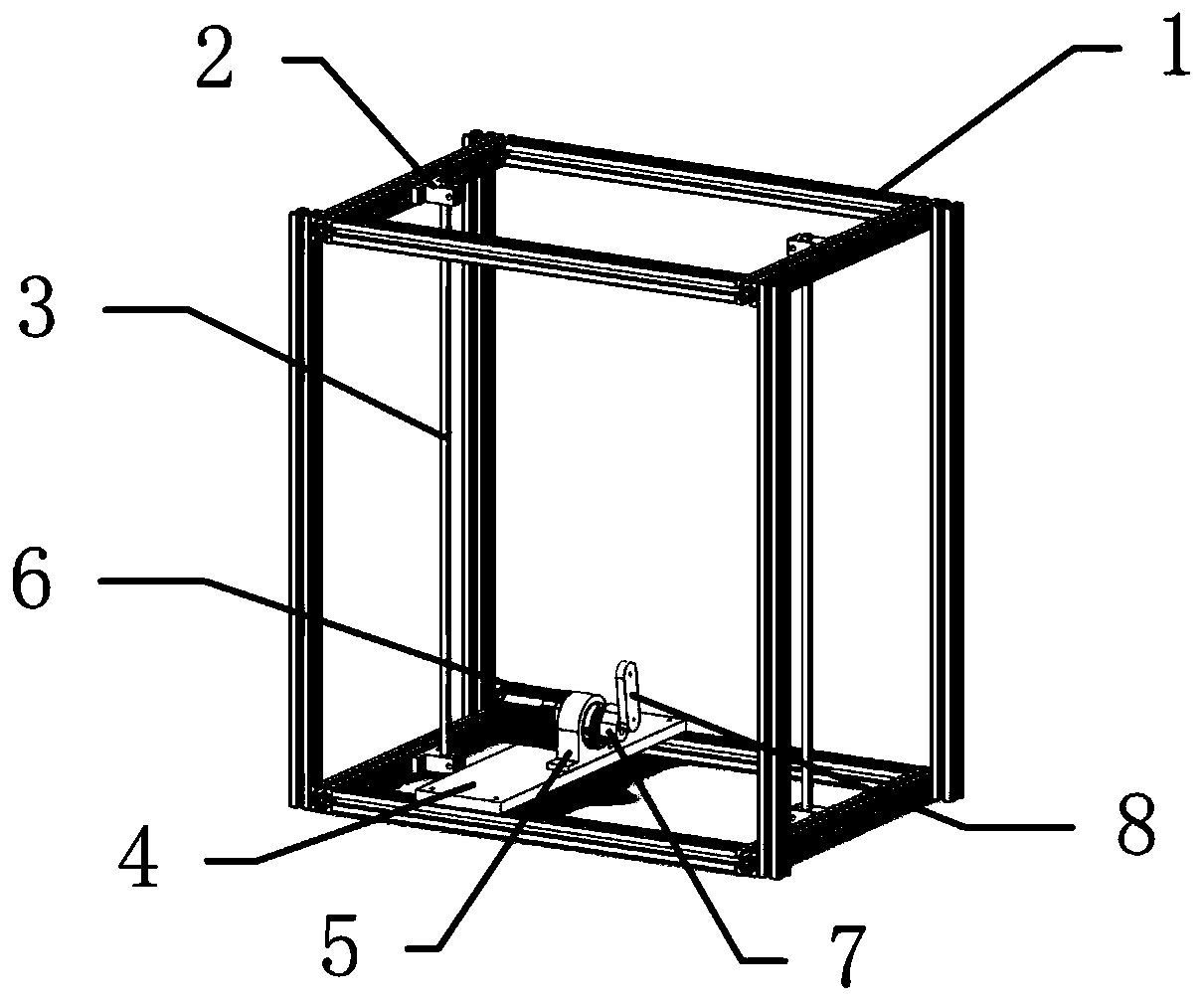

[0021] Low frequency vibration isolation test benches such as figure 2 As shown, the vibration source table includes a vibration source table base 1, a guide rod support seat 2, a guide rod 3, a motor installation base 4, a motor support 5, a vibration source motor 6, a swing arm 7, a connecting rod 8, Vibration table 9, linear bearing slider 10, vibration isolator installation base plate 11, vibration isolator 12 and connecting rod hinged seat 13. The function of the vibration source table is to provide a vibration source with adjustable amplitude and frequency as the input vibration of the vibration isolator under test.

[0022] Such as image 3 As shown, a guide rod support seat 2 is installed on the base 1 of the vibration source table, and the guide rod 3 is vertically fixed in the guide rod support seat 2 . A motor installation base 4 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com