Abrasion wheel and sample preparation method for Akron abrasion test

An abrasive wheel and experimental technology, applied in the preparation of test samples, instruments, measuring devices, etc., can solve problems such as unstable bonding effect, damage at joints, loss of abrasive wheel quality, etc., to avoid poor bonding effect Stabilize, reduce experimental error, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

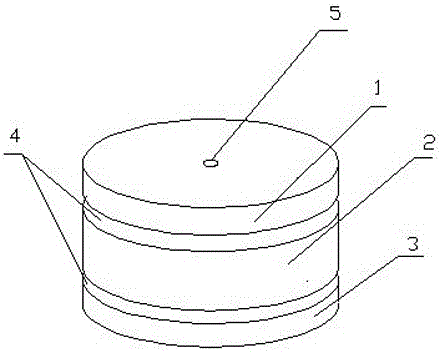

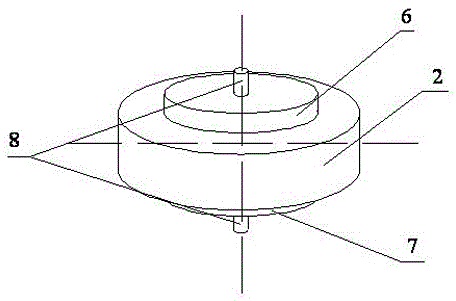

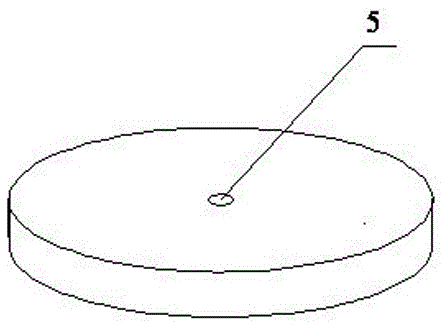

Image

Examples

Embodiment 1

[0036] Using the above-mentioned technical scheme of the sample preparation method for the Akron abrasion test, use the rubber compound A to wrap the experimental rubber strip on the metal wear wheel for vulcanization, use the overflow rubber groove to remove the excess waste rubber, and wrap the experimental rubber strip Direct vulcanization Akron abrasion experiments were performed on metallic abrasive wheels.

Embodiment 2

[0038] This embodiment adopts the same method as that of Embodiment 1, the difference is that rubber compound B is used.

[0039] Akron abrasion data are shown in Table 1 below.

[0040] Table 1. Acron Abrasion Data

[0041]

[0042] It can be seen from Table 1 that, in the case of the same test rubber, the stability of the experimental data using the new method is significantly higher than that of the original method, and the wear volume decreases, reducing the error caused in the sample preparation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com