Alloy-fluororesin double-layer self-lubricating wear-resistant composite material, preparation method and friction pair thereof

A composite material and fluororesin technology, which is applied in the field of alloy-fluororesin double-layer self-lubricating wear-resistant composite materials and friction pairs, which can solve the problems of precision and mechanical operation, large amount of wear and influence on relative spatial position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing an alloy-fluororesin double-layer self-lubricating and wear-resistant composite material, comprising the following steps:

[0025] A) Pretreating the surface of the alloy matrix to obtain an alloy matrix with a surface roughness of Ra;

[0026] B) applying the fluororesin mixture on the surface of the alloy matrix with a roughness of Ra, and performing stepwise vacuum sintering to obtain an alloy-fluororesin double-layer self-lubricating wear-resistant composite material;

[0027] The fluororesin mixture includes first fluororesin particles with a particle size of 0.5-1.2 times Ra and second fluororesin particles with a particle size of 2.5-4.0 times Ra.

[0028] In the present invention, the alloy matrix is preferably a copper alloy, more preferably a wear-resistant copper alloy such as tin bronze, copper-nickel-tin, the thickness of the copper alloy matrix layer is 0.05-5mm, and the Sn content in the tin bronze is 4 ~ 1...

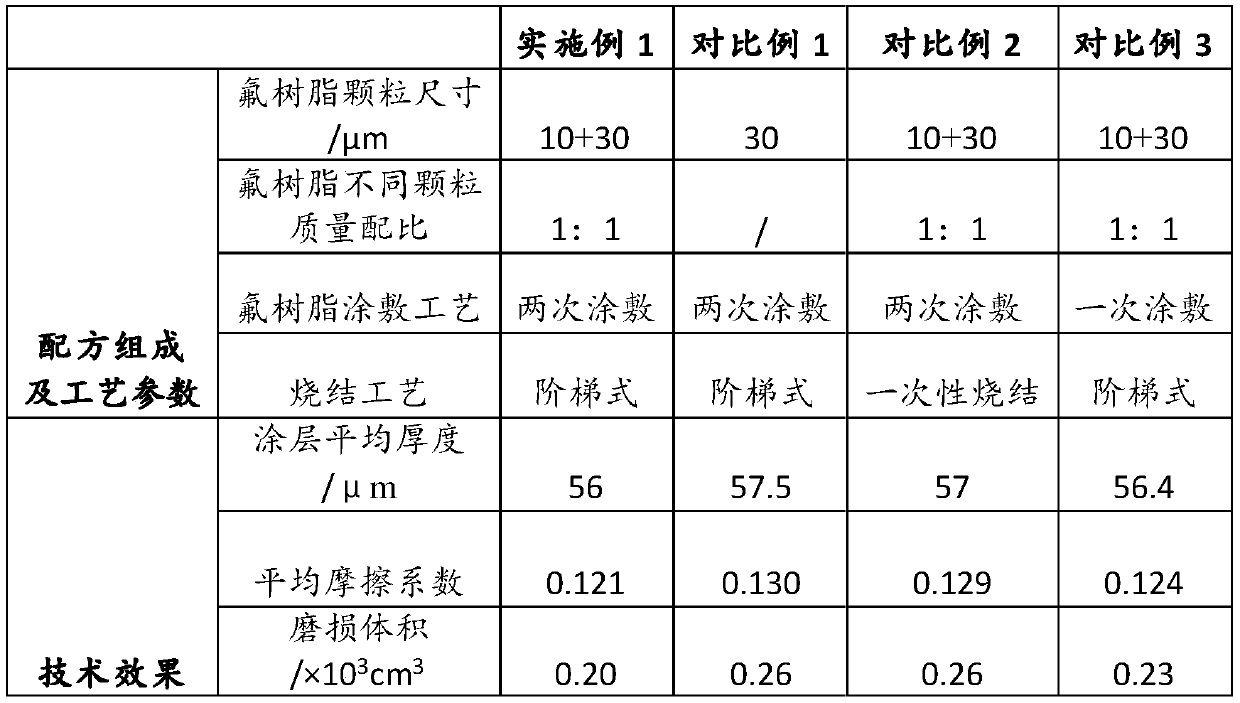

Embodiment 1

[0052] The copper alloy ZCuSn5Pb5Zn5 is made into a copper strip with a length of 50 mm, a width of 20 mm and a thickness of 0.1 mm. The surface of the copper strip is rolled to obtain a porous and loose structure with a surface roughness of Ra 12.5.

[0053] Degrease and perform ultrasonic cleaning, dry and put into graphite mold; dissolve tetrafluoroethylene and hexafluoropropylene copolymer (FEP) in polytetrafluoroethylene (PTFE) suspension, mass ratio 1:1, polytetrafluoroethylene (PTFE) has an average particle size of 10 microns, tetrafluoroethylene and hexafluoropropylene copolymer (FEP) has an average particle size of 30 microns, and is fully stirred and mixed to form a paste mixture; the mixture is pressed into the surface of the copper alloy strip by cold pressing, double The layer material is first dried in a vacuum sintering furnace to remove moisture and organic solvents. The drying temperature is 180 ° C, the drying time is 2 hours, the furnace is naturally cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com