Hydrogenated nitrile rubber material for manipulator clamping jaw of wire drawing machine, and preparation method thereof

A hydrogenated nitrile rubber and manipulator technology, which is applied in the field of optical fiber manufacturing and processing, can solve problems such as short service life, poor wear resistance, and high surface viscosity, and achieve reduced surface contact and cortical wear, excellent wear resistance, and wire drawing The effect of process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

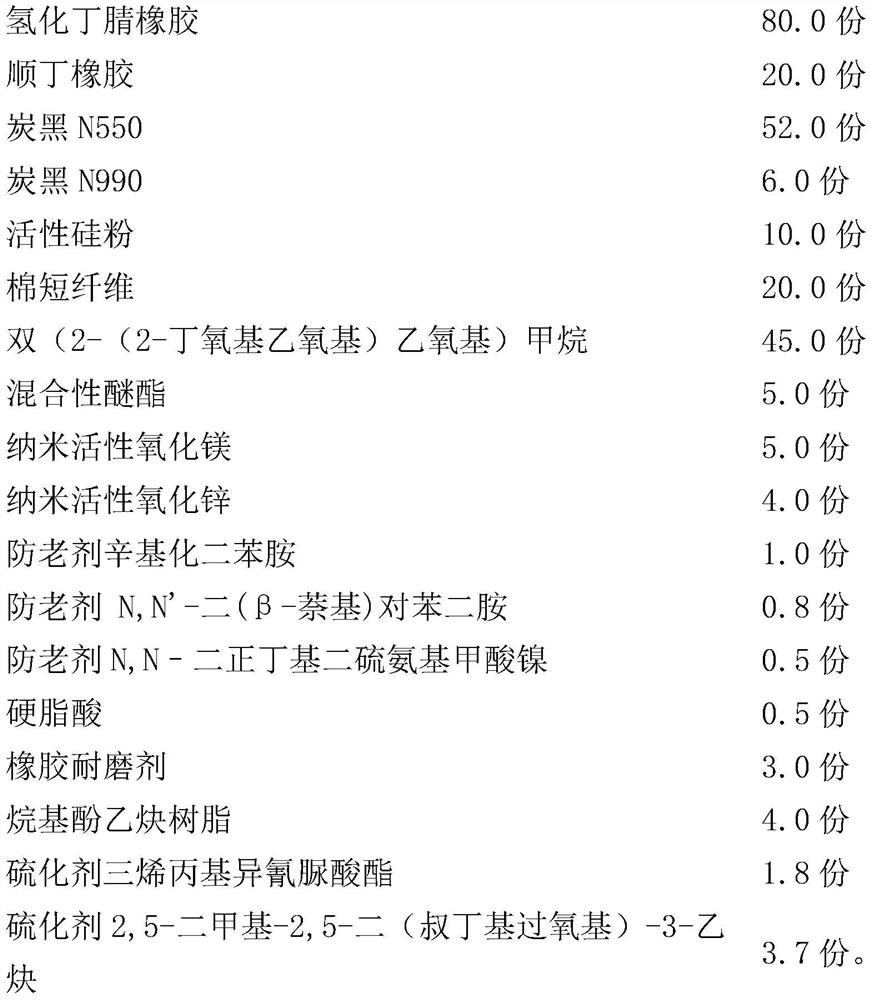

Embodiment 1

[0081] A kind of preparation method of the hydrogenated nitrile butadiene rubber material that is used for wire drawing machine manipulator jaw, comprises the following steps:

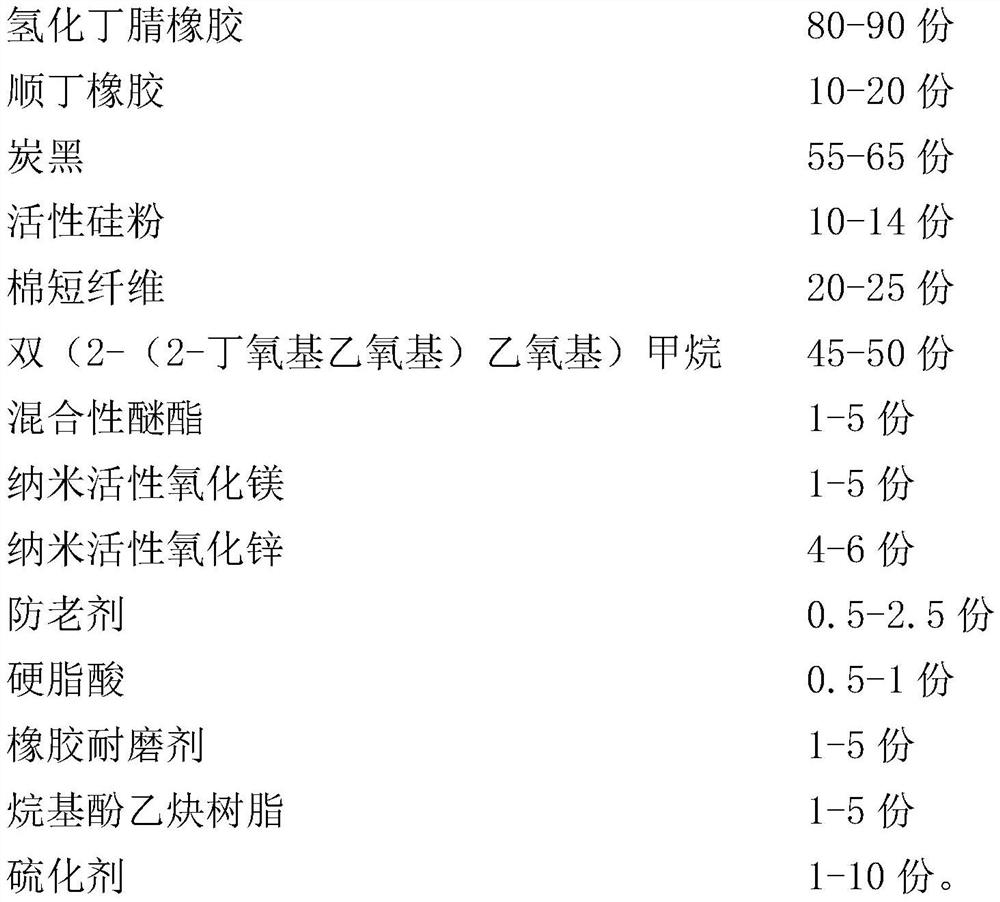

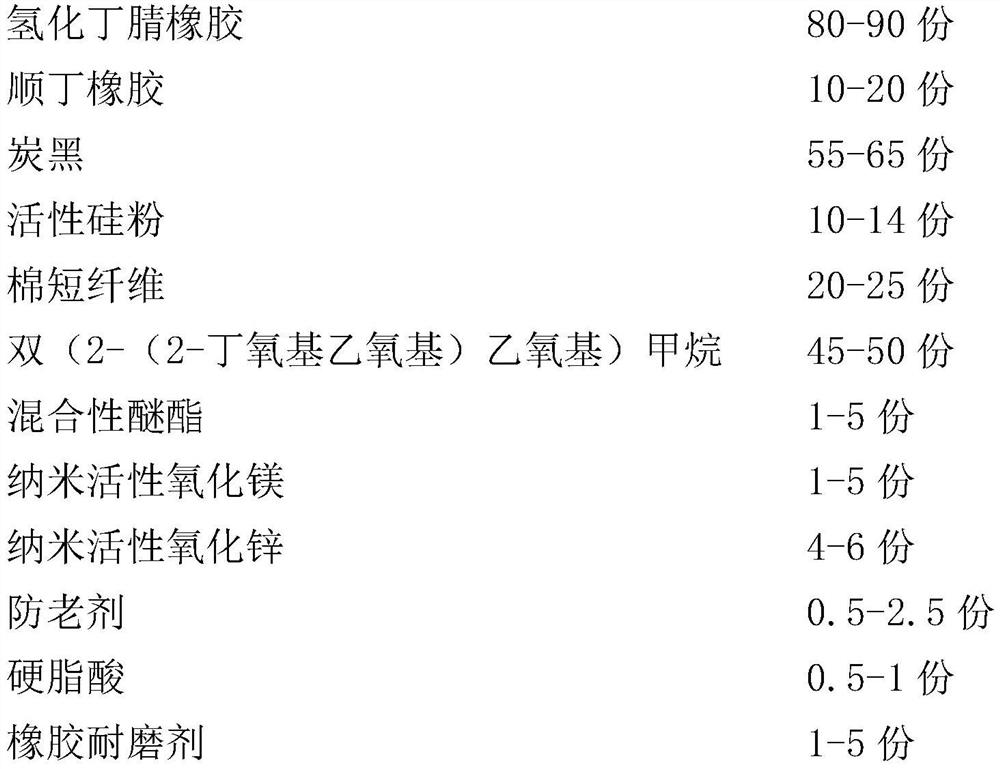

[0082] (1) carry out the batching of raw material according to the composition of each component that table 1 provides;

[0083] (2) 80kg hydrogenated nitrile rubber and 20kg cis-butadiene rubber are placed in the internal mixer for plasticating and mixing, add 52kg carbon black N550, 6kg carbon black N990, 10kg active silicon powder, 20kg cotton short fiber, 45kg double (2 -(2-butoxyethoxy)ethoxy)methane, 0.5kg stearic acid, 1kgODA, 0.8kgDNP kg and 0.5kgNBC of anti-aging agent, mix well; then add 5kg nano active magnesium oxide, 4kg nano active zinc oxide , 5kg of mixed ether ester, 3kg of rubber wear-resistant agent SD1513, 4kg of alkylphenol acetylene resin HY-2006, mix evenly, and then release the sheet to obtain the mixed rubber; place the mixed rubber for 36 to 48 hours in the banburying In the ...

Embodiment 2

[0086] Carry out the batching of raw material according to the composition of each component that table 1 provides; Preparation method is identical with embodiment 1, and difference is that mixed ether ester is selected from dibutyl phthalate;

[0087] Among them, the roll temperature of the open mixer with vulcanizing agent is 50°C; the temperature of the internal mixing chamber of the internal mixer without vulcanizing agent is 140°C.

Embodiment 3

[0089] Carry out the batching of raw material according to the composition of each component that table 1 provides; Preparation method is identical with embodiment 1, and difference is that mixed ether ester is selected from dioctyl adipate;

[0090] Among them, the roll temperature of the open mill with vulcanizing agent added is 80°C; the temperature of the internal mixing chamber of the internal mixer without vulcanizing agent is 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com