Abrasion-resistant antistatic odorless shoe sole rubber and its preparation method and application

An anti-static, odorless technology, applied in the field of rubber processing, can solve the problems of reduced service life, odor, and frosting of rubber shoes, and achieve good wear resistance, wide material sources, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

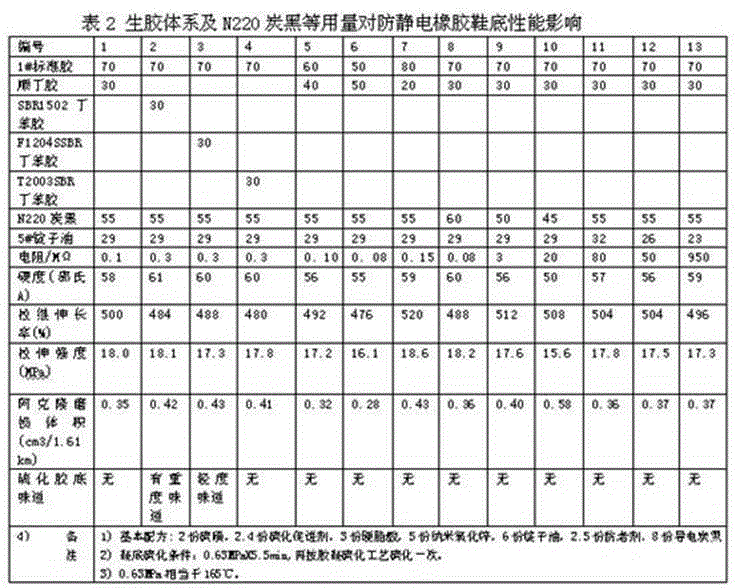

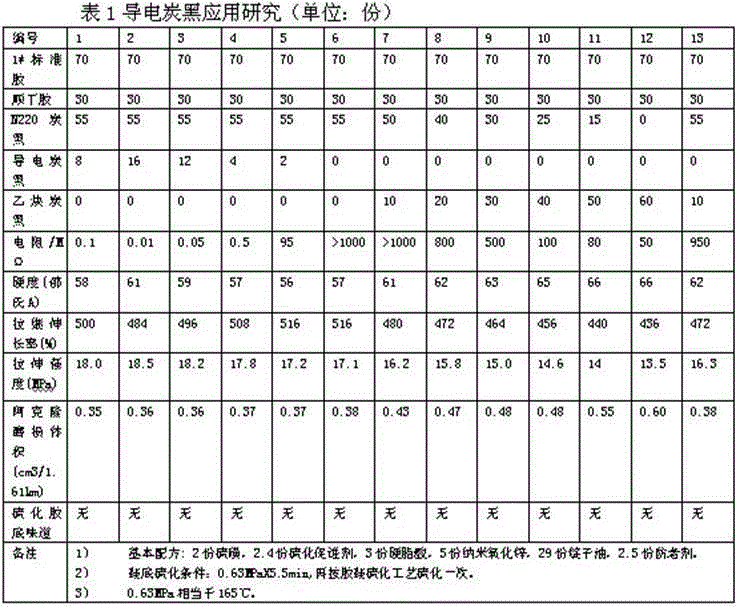

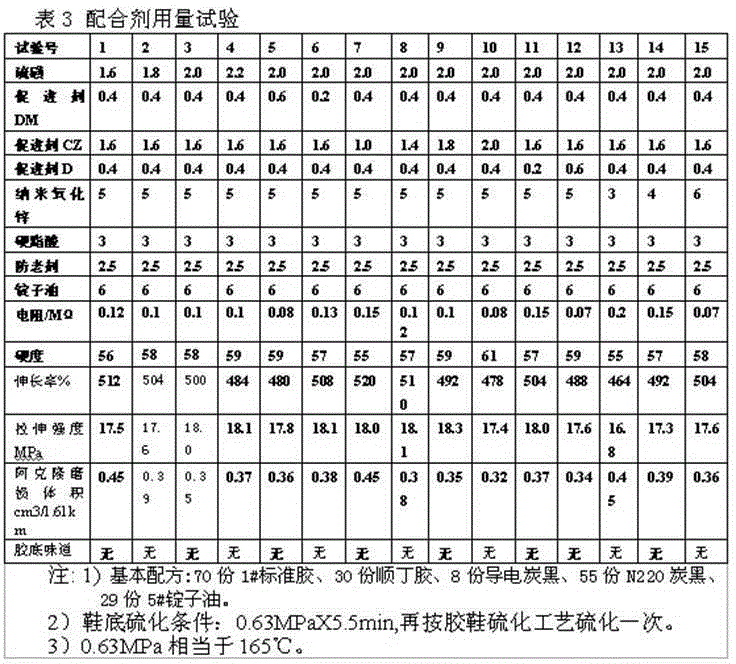

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention: wear-resistant antistatic tasteless sole rubber, calculated by weight fraction, more preferred technical scheme is, calculated by weight fraction, comprises 70 parts of 1# standard rubber, 30 parts of butadiene rubber, 2 parts of sulfur, 2.4 parts of vulcanization accelerator, 3 parts of stearic acid, 5 parts of nano zinc oxide, 29 parts of 5# spindle oils, 55 parts of N220 carbon black, 2.5 parts of anti-aging agent and 8 parts of conductive carbon black; Described vulcanization accelerator is, Every 2.4 parts of vulcanization accelerator is made up of 0.4 part of accelerator DM, 1.6 parts of accelerator CZ and 0.4 part of accelerator D; the described anti-aging agent is that every 2.5 parts of anti-aging agent is composed of 0.5 part of anti-aging agent H and 0.5 part of anti-aging agent RD And 1.5 parts of anti-aging agent KY-405L.

[0027] The preparation method of wear-resistant, anti-static and odorless shoe sole rubber, 1) P...

Embodiment 2

[0029] Embodiment 2 of the present invention: wear-resistant antistatic tasteless shoe sole rubber, calculated by weight fraction, more preferred technical scheme is, calculated by weight fraction, comprises 65 parts of 1# standard rubber, 35 parts of butadiene rubber, 1.8 parts of sulfur, 2.6 parts of vulcanization accelerator, 2.5 parts of stearic acid, 4.5 parts of nano zinc oxide, 25 parts of 5# spindle oils, 50 parts of N220 carbon black, 2 parts of anti-aging agent and 7 parts of conductive carbon black; Described vulcanization accelerator is, Every 2.4 parts of vulcanization accelerator is made up of 0.4 part of accelerator DM, 1.6 parts of accelerator CZ and 0.4 part of accelerator D; the described anti-aging agent is that every 2.5 parts of anti-aging agent is composed of 0.5 part of anti-aging agent H and 0.5 part of anti-aging agent RD And 1.5 parts of anti-aging agent KY-405L.

[0030] The preparation method and application are the same as in Example 1.

Embodiment 3

[0031]Embodiment 3 of the present invention: wear-resistant antistatic odorless sole rubber, calculated by weight fraction, more preferred technical scheme is, calculated by weight fraction, comprises 75 parts of 1# standard rubber, 25 parts of butadiene rubber, 2.2 parts of sulfur, 2.2 parts of vulcanization accelerator, 3.5 parts of stearic acid, 5.5 parts of nanometer zinc oxide, 32 parts of 5# spindle oils, 60 parts of N220 carbon black, 3.0 parts of antioxidant and 9 parts of conductive carbon black; Described vulcanization accelerator is, Every 2.4 parts of vulcanization accelerator is made up of 0.4 part of accelerator DM, 1.6 parts of accelerator CZ and 0.4 part of accelerator D; the described anti-aging agent is that every 2.5 parts of anti-aging agent is composed of 0.5 part of anti-aging agent H and 0.5 part of anti-aging agent RD And 1.5 parts of anti-aging agent KY-405L.

[0032] The preparation method and application are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com