Safety monitoring and auxiliary operation method of petrochemical plant based on cloud computing

A technology for safety monitoring and petrochemical equipment, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., to achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

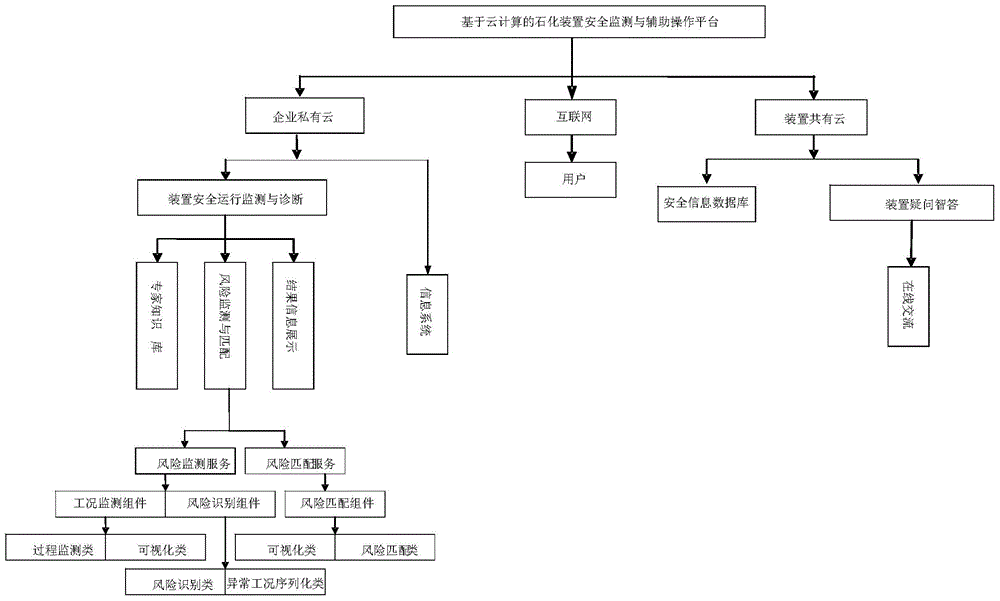

[0028] The petrochemical plant safety monitoring and auxiliary operation method based on cloud computing provided by this patent mainly includes enterprise private cloud and device shared cloud, users connect to the platform through the Internet, and enterprise private cloud mainly includes device safety operation monitoring and diagnosis module and information system Module, the device shared cloud mainly includes the device question answering module and the safety information database. The device safety operation monitoring and diagnosis module mainly includes three levels: risk monitoring and matching, expert knowledge base and result information display. The device question answering module mainly includes The information search engine and online communication platform based on cloud computing, the data retrieved by the information search engine based on cloud computing comes from the security information database and the information system.

[0029]The safety operation mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com