Contingency plan co-simulation method for chemical laboratory hazardous material management and systems thereof

A chemical laboratory and emergency plan technology, which is applied in the field of collaborative simulation of chemical laboratory dangerous goods management emergency plan and chemical laboratory dangerous goods management emergency plan collaborative simulation system, can solve the problem that the number of drills is limited, and various situations cannot be truly simulated. It is difficult to quickly improve the practical emergency skills of the trainees to achieve the effect of improving fidelity and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

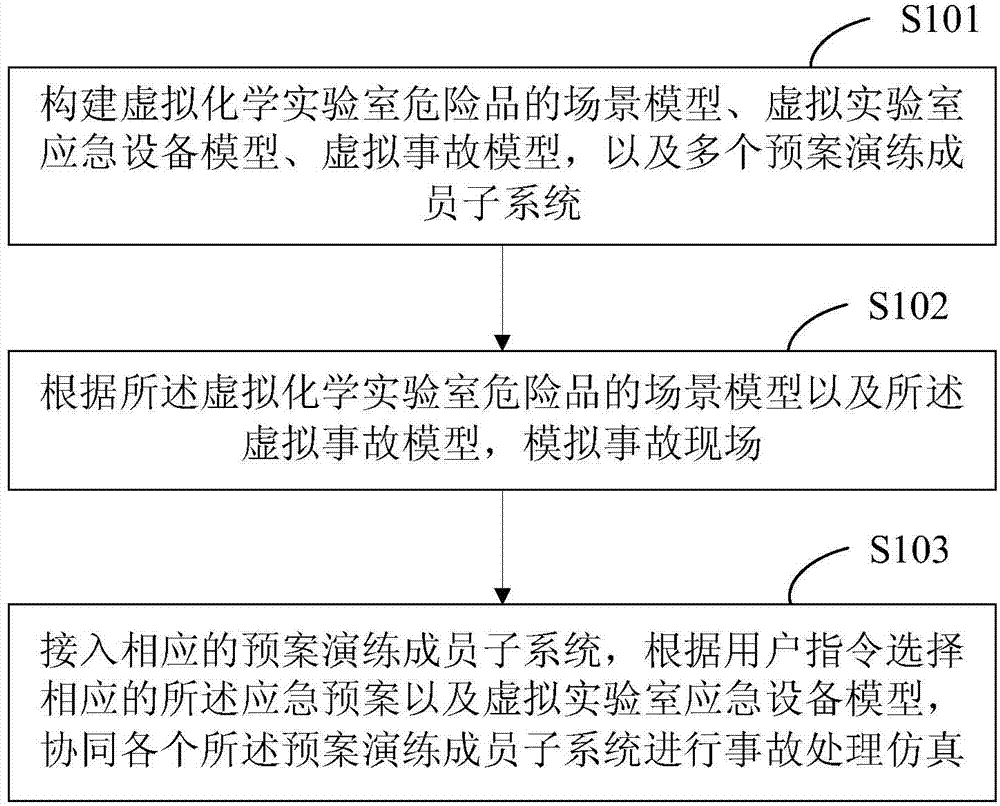

[0019] see figure 1 , figure 1 It is a schematic flow chart of the collaborative simulation method for the emergency plan of the chemical laboratory dangerous goods management of the present invention.

[0020] The chemical laboratory dangerous goods management emergency plan collaborative simulation method includes the following steps:

[0021] S101, constructing a scene model of dangerous goods in the virtual chemical laboratory, a virtual laboratory emergency equipment model, a virtual accident model, and multiple member subsystems for contingency plans;

[0022] S102, simulating an accident scene according to the scene model of the dangerous goods in the virtual chemical laboratory and the virtual accident model;

[0023] S103, access the corresponding plan drill member subsystem, select the corresponding emergency plan and virtual laboratory emergency equipment model according to the user instruction, and cooperate with each plan drill member subsystem to perform accide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com