Degradation model consistency testing method catering to space shapes and error ranges

A technology of degradation model and error range, which is applied in the field of degradation model consistency inspection, can solve the problem that it is difficult to meet the requirements of engineering evaluation, failure to consider the degradation model consistency inspection method from other factors, failure to reflect the degradation model change process and Law and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

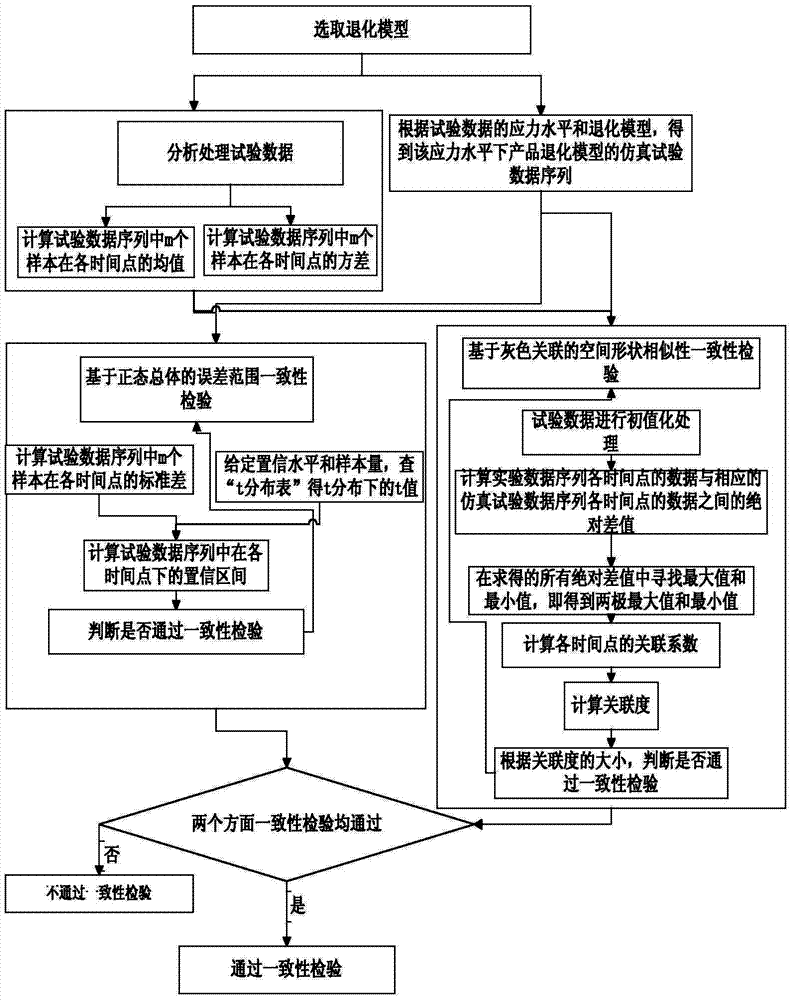

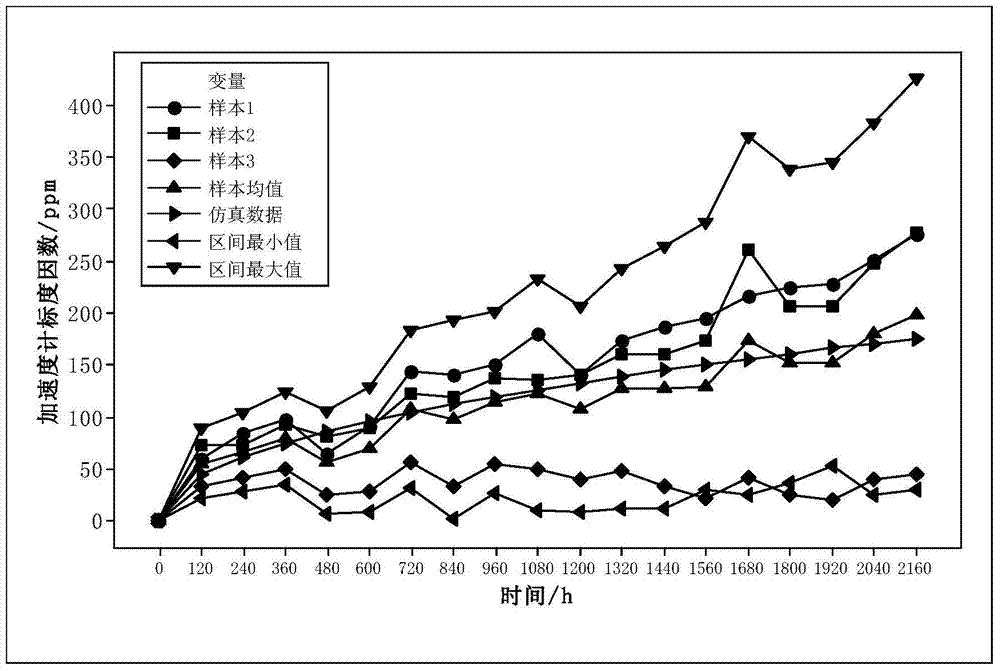

[0062] The following examples are based on the attached figure 1 The flow shown is implemented, and the present embodiment selects the degradation model of the accelerometer scale factor as an implementation example, and the scale factor is used as one of the key performance parameters of the accelerometer. an effective way.

[0063] See figure 1 , 2 As shown, the present invention is a method for checking the consistency of the degradation model for spatial shape and error range. Taking a certain accelerometer scale factor as an example, its specific implementation steps are as follows:

[0064] Step 1: Select the degradation model of the accelerometer scale factor as

[0065] K 1 = ( 0.152 e - 2704....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com