Electric kettle thermostat

A technology for electric kettles and thermostats, applied in the direction of thermal switch parts, etc., can solve problems such as height not meeting the standard, high processing technology, interference fit or excessive fit, etc., to achieve firm and stable screw connection and structural installation. The effect of firm and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

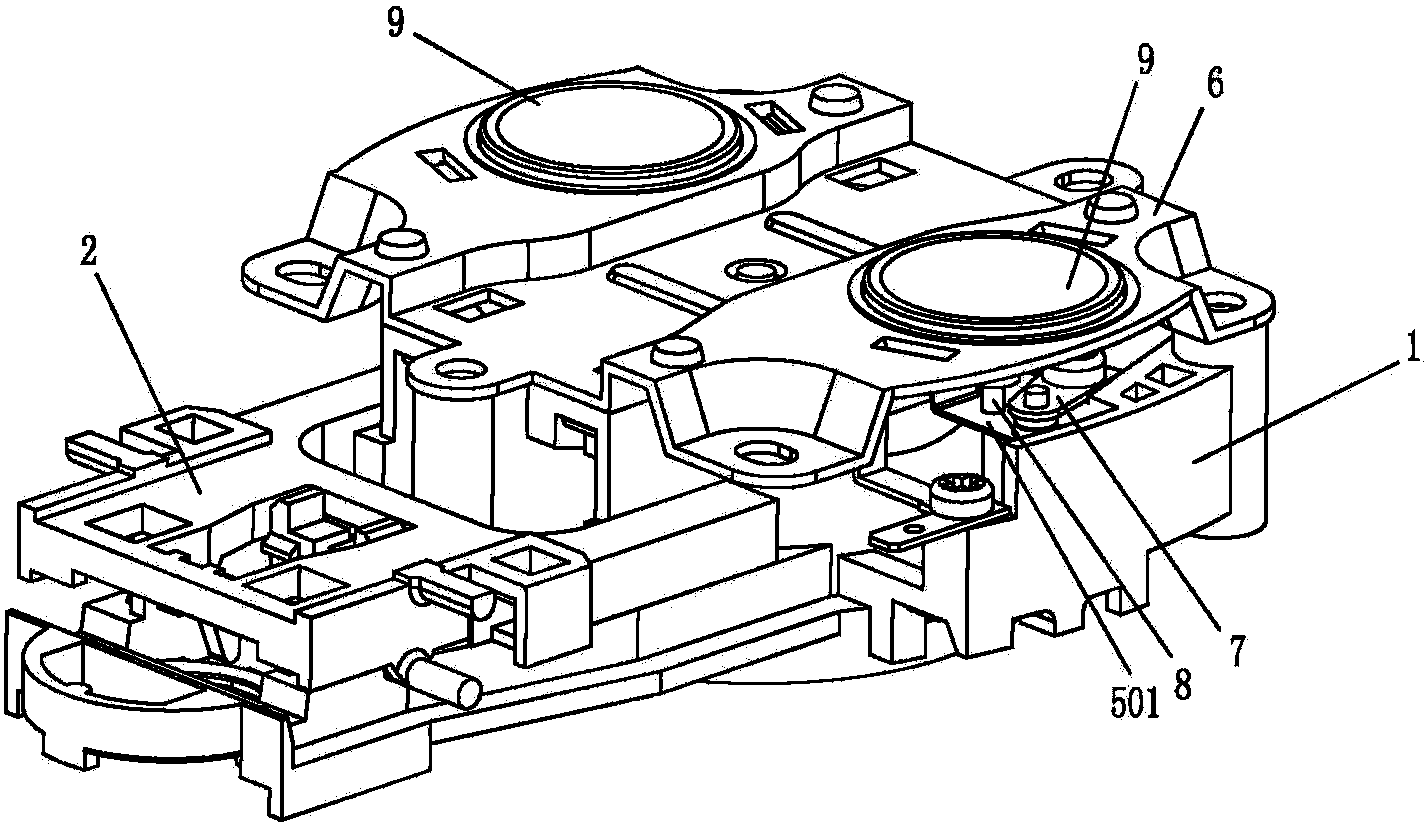

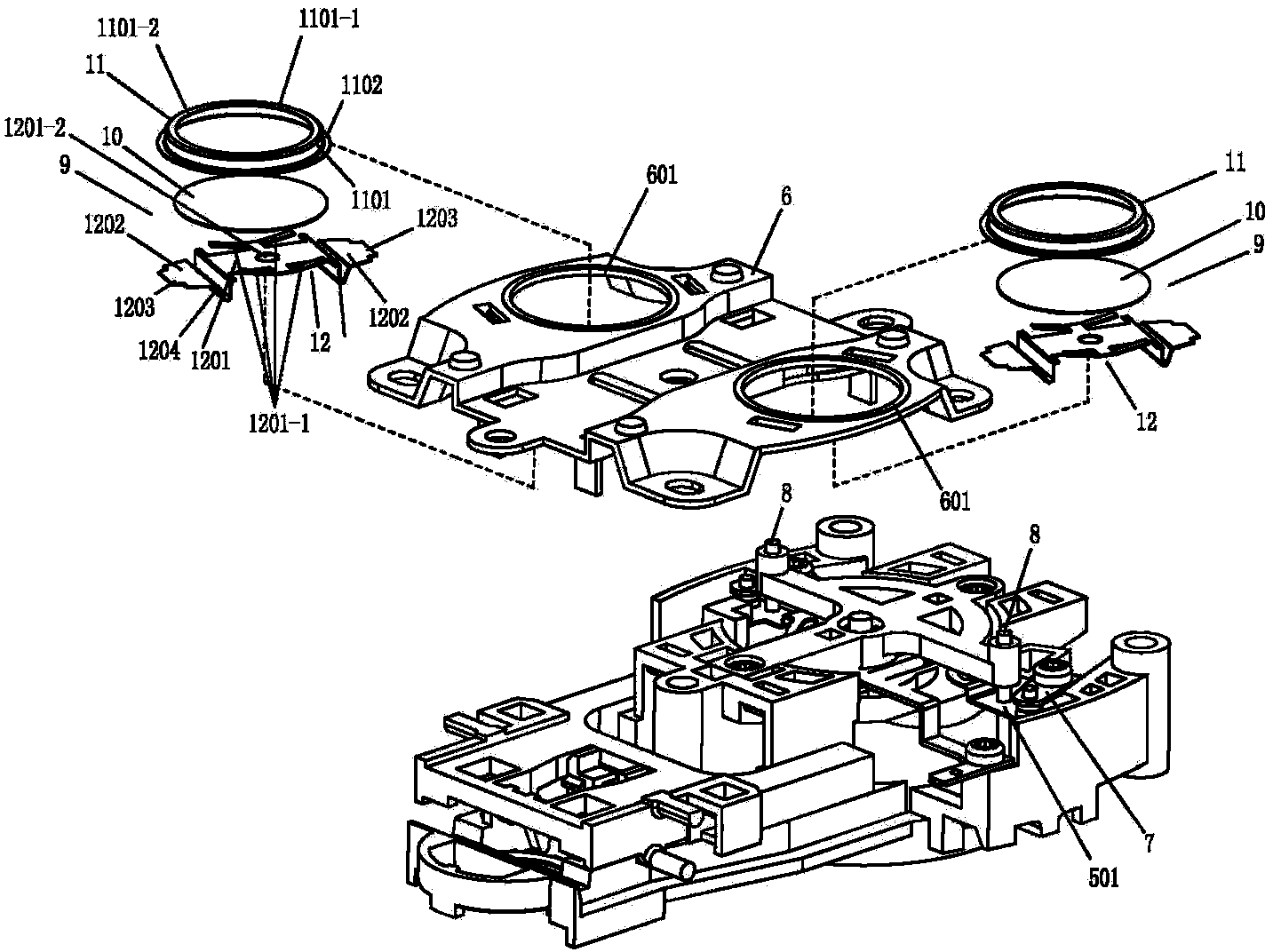

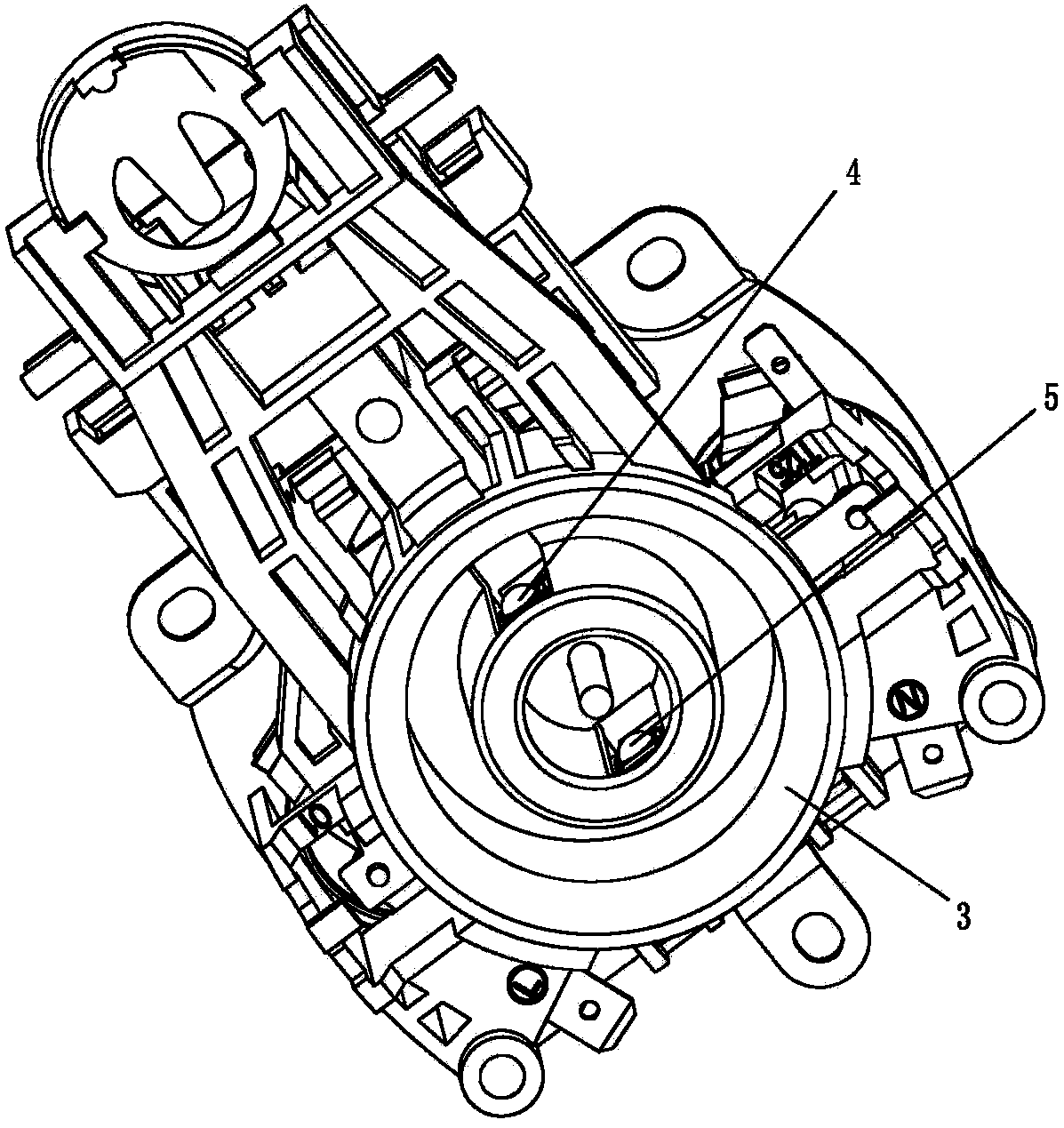

[0038] Such as Figure 1 to Figure 8 As shown, an electric kettle thermostat includes a plastic upper seat 1 and a rocker 2. The bottom end of the plastic upper seat 1 is provided with an insertion part 3, and the live wire shrapnel 4 and the neutral wire shrapnel 5 are installed on the insertion part 3. The plastic upper seat 1. The top end is connected with an insulating cover plate 6, which is characterized by;

[0039]Two through holes 601 are respectively opened on both sides of the insulating cover plate 6, the plastic upper seat 1 below the insulating cover plate 6 is provided with a positioning platform 101, and the live wire shrapnel 4 and the neutral wire shrapnel 5 are respectively provided with live wires extending to the positioning platform 101. The positioning conductive sheet 401 and the neutral line positioning conductive sheet 501, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com