Pressure sensor array and manufacturing method thereof

A pressure sensor and array technology, applied in the sensor field, can solve the problems of sensitivity and low resolution of the pressure sensor, and achieve the effects of saving preparation cost, simple preparation process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

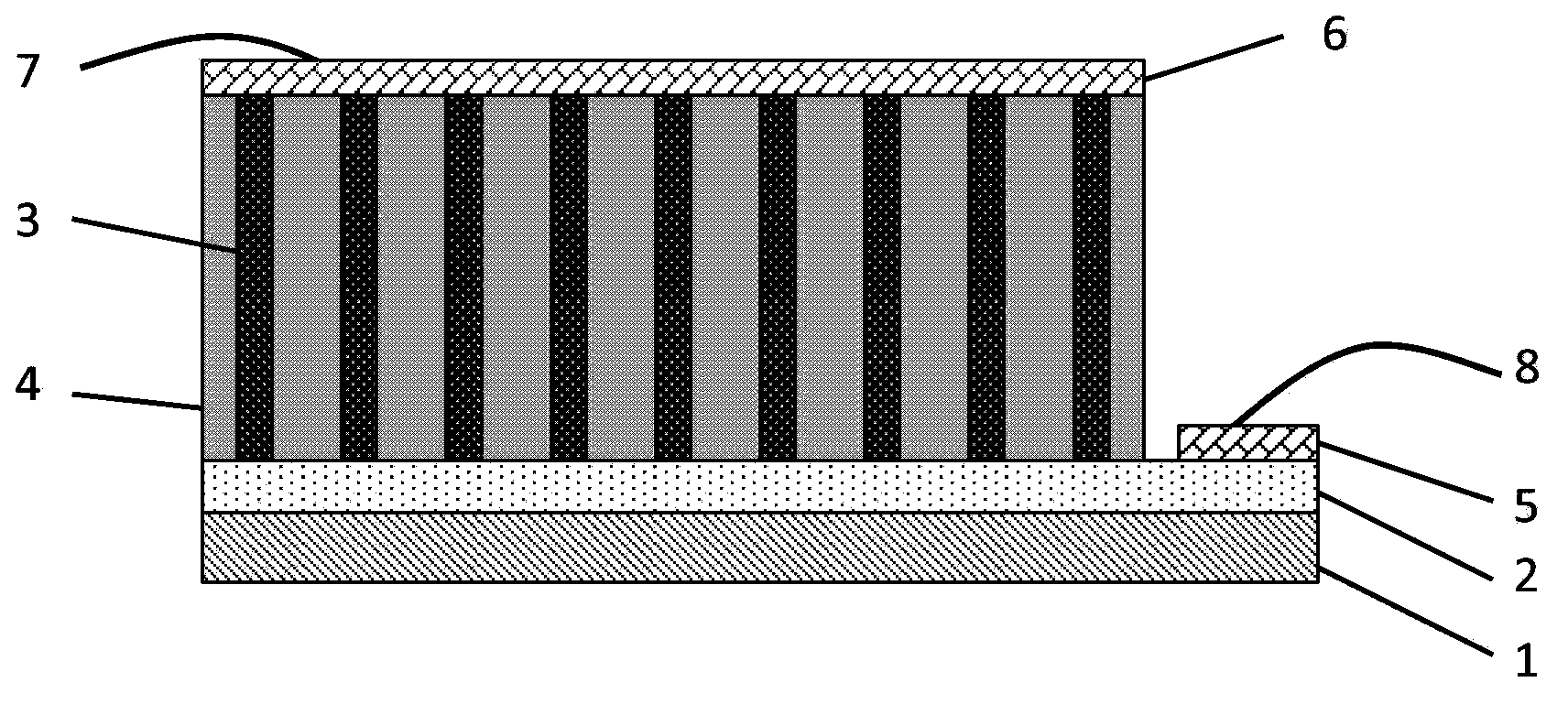

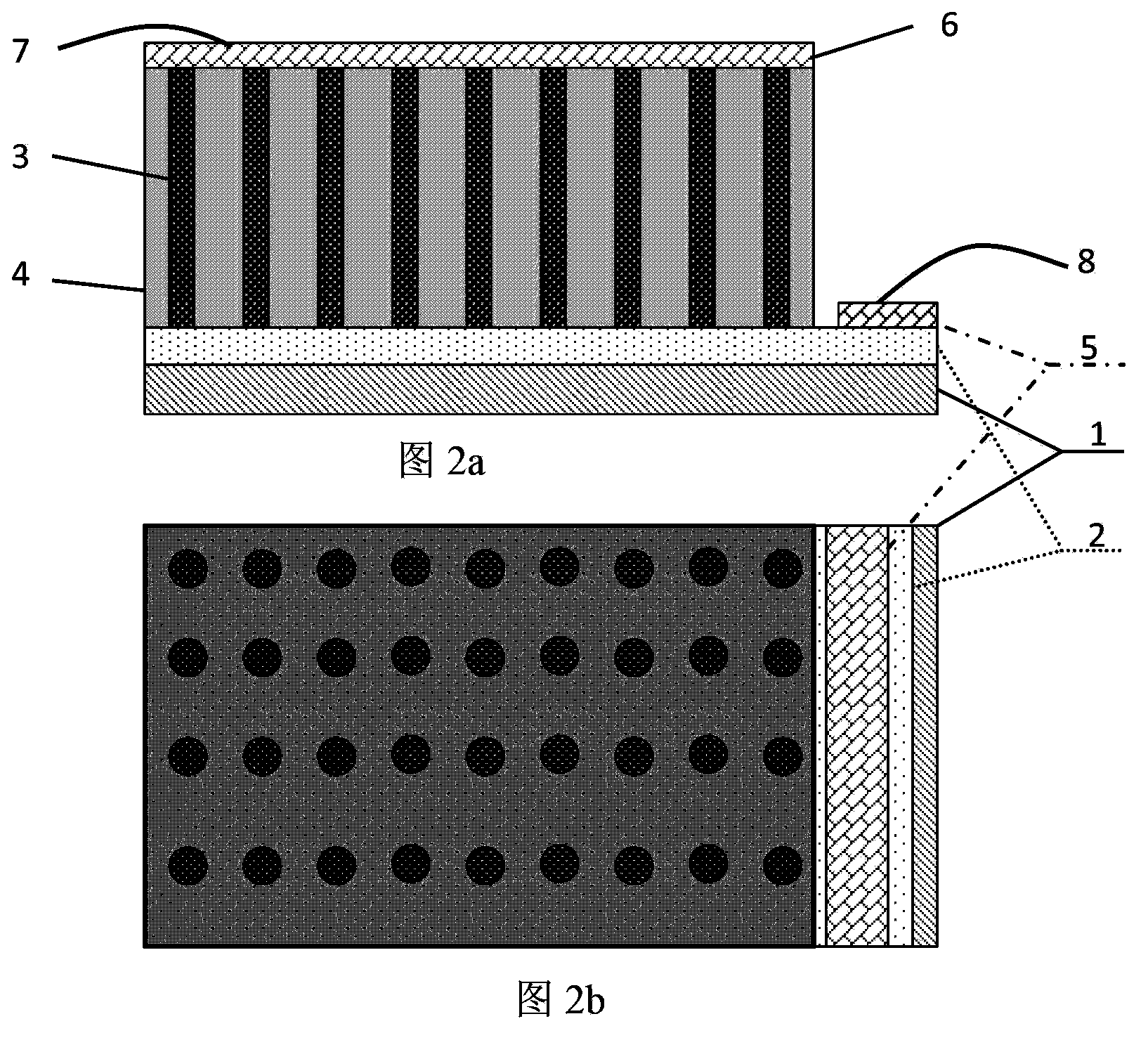

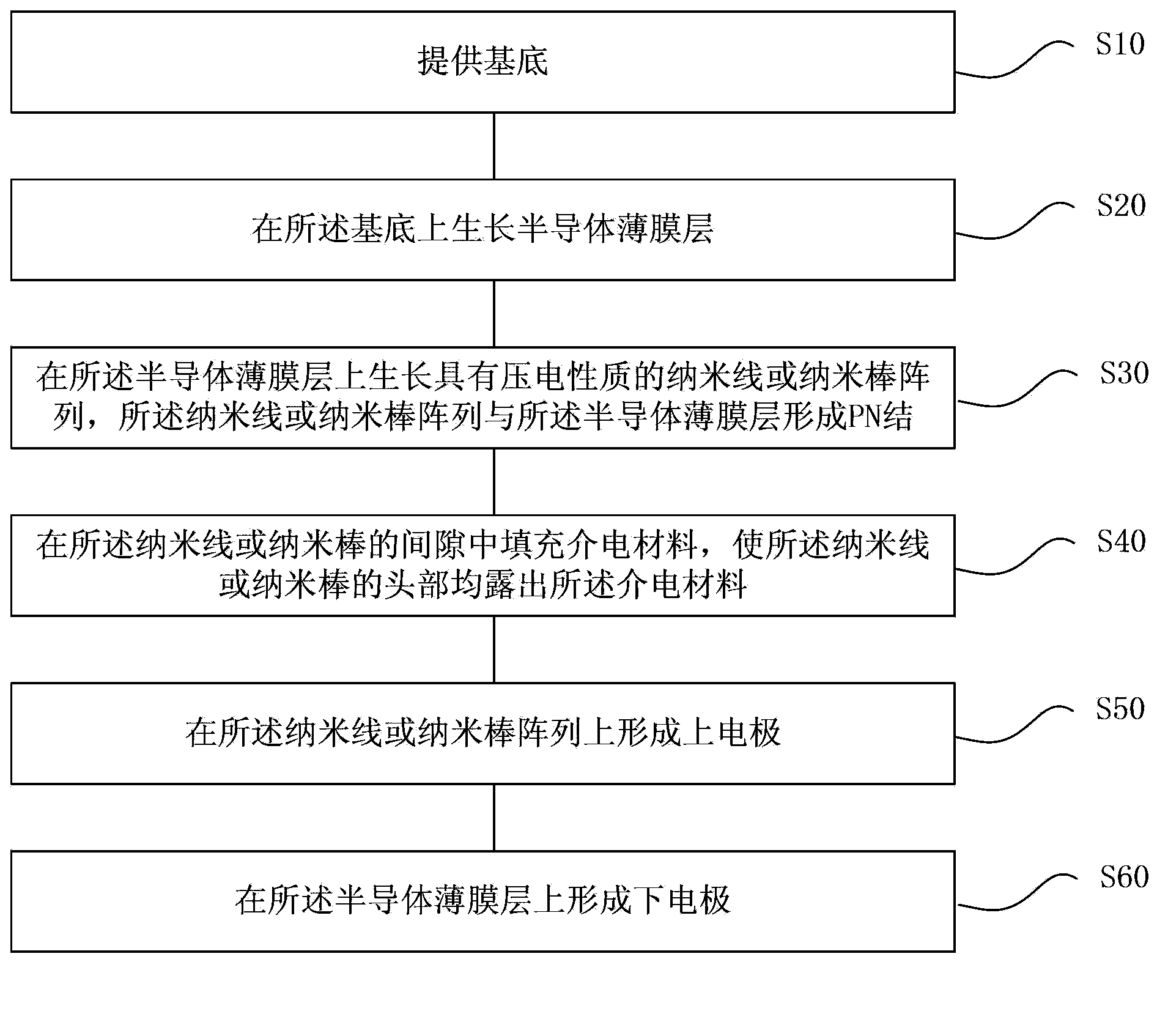

[0037] For the pressure sensor array in this embodiment, see figure 1 and Fig. 2, including: substrate 1; semiconductor film layer 2 on the substrate; nanowires or nanorod arrays 3 with piezoelectric properties on the semiconductor film layer 2; gaps between nanowires or nanorod arrays 3 are filled with dielectric Material 4, the dielectric material may be transparent or non-transparent or translucent; an upper electrode 6 on the nanowire or nanorod array 3; and a lower electrode 5 on the semiconducting thin film layer 2. Wherein, the nanowire or nanorod array 3 forms a luminescent PN junction with the semiconductor thin film layer 2 . The pressure sensor array also includes upper electrode lead-out wires 7 and lower electrode lead-out wires 8 which are necessarily related to the pressure sensor array according to the present invention, and are used for applying driving voltage to the pressure sensor array device.

[0038] Since the nanowire or nanorod array 3 forms a lumines...

Embodiment 2

[0068] For the pressure sensor array in this embodiment, see Figure 4 , fabricated on the substrate 11, including: the bottom electrode 21 on the substrate 11, the sensing cell array on the bottom electrode 21 and the top electrode 61 on the sensing cell array, wherein the sensing cell is composed of the region 31 and the region 41 to form a light-emitting PN junction, wherein the material of the P-type region and / or N-type region of the PN junction is a piezoelectric material; the gap of the sensing unit is filled with a dielectric material 51, and the dielectric material 51 can be Transparent or opaque or translucent. The pressure sensor array also includes wires 71 and wires 81 drawn from the bottom electrode 21 and the top electrode 61 , which are necessarily related to the pressure sensor array according to the present invention. In the present invention, the light-emitting diode (PN junction) is used as the basic pixel unit, and the driving voltage is applied to the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com