Grinding vertical-type grain polisher

一种碾谷机、立式的技术,应用在谷物处理、谷物去荚、谷物脱壳等方向,能够解决调整需要较长时间、产生碎米等问题,达到结构简单、构造简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (the whole frame)

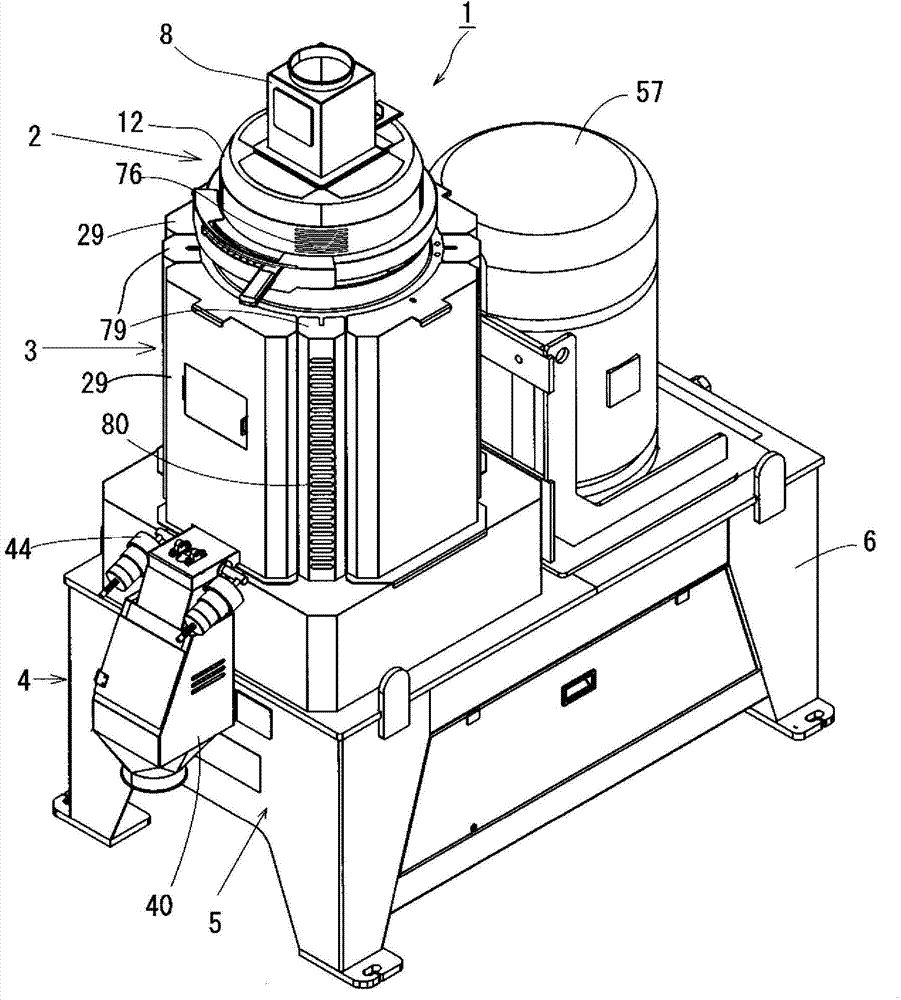

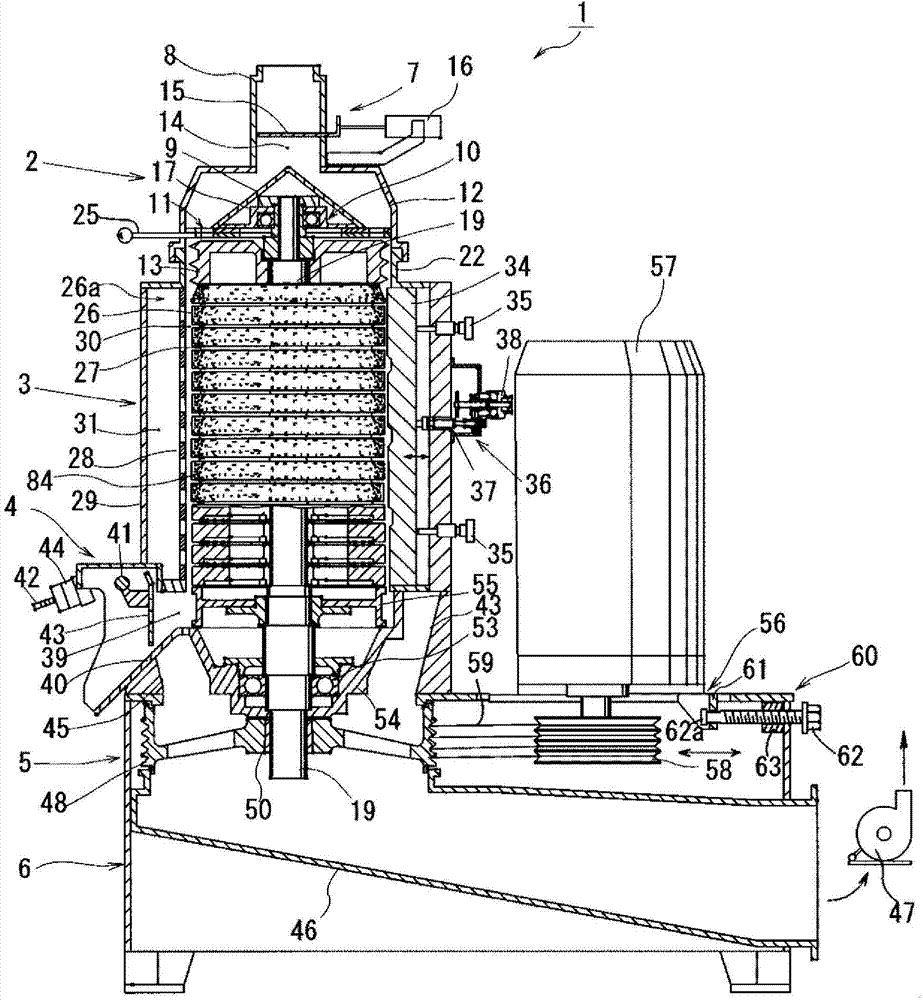

[0049] Such as figure 1 , figure 2 As shown, the grinding type vertical rice milling machine 1 according to one embodiment of the present invention is provided with the following main constituent elements and constitutes: a grain supply part 2 that supplies raw material grain grains that should be milled; The grain milling part 3 that carries out milling while the grain grain that receives is moved downward; Bran collecting part 5 ( figure 2 ); and the main body base portion 6 for supporting the body and the motor as a driving source.

[0050] (Grain Supply Department)

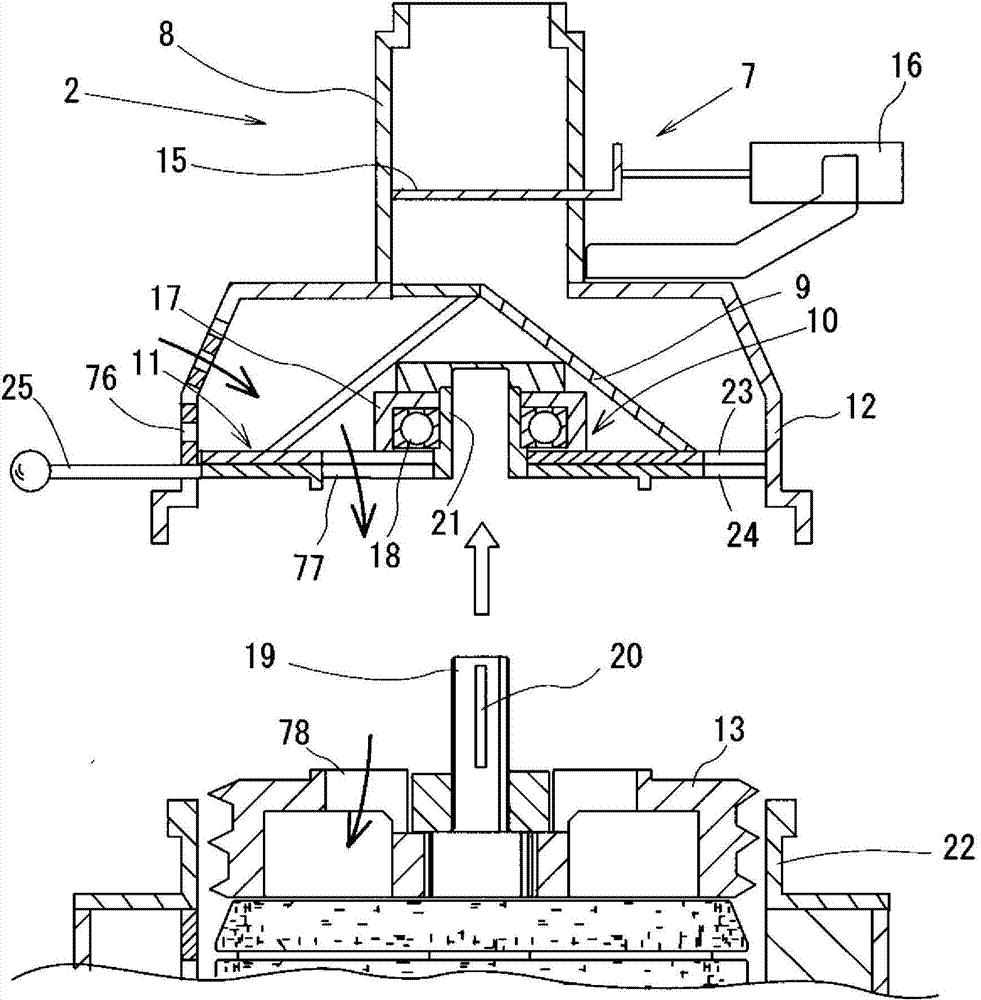

[0051] The above-mentioned grain supply unit 2 includes: a grain supply cylinder 8 for receiving raw material grains supplied from a raw material box (not shown) etc.; The opening and closing plate mechanism 7 ( figure 2 ); the conical guide body 9 that radially disperses the grain grains received from the grain supply cylinder 8 in the circumferential direction; the upper ...

Embodiment 2

[0088] Figures 9 to 12 Main part of Example 2 is shown. The overall structure of the grinding type vertical rice miller 1 in this embodiment, the structure of the grain supply part, the grinding mill part, the grain discharge part, the bran collection part, and the main body base part are the same as the above-mentioned embodiment 1. Same notation, but quoting instructions.

[0089] Compared with Example 1, Example 2 has features in the resistance body device 36 and the external air intake structure.

[0090] 〔Resistance body device〕

[0091] The resistance body device 36 is longer in the axial direction of the main shaft 19, and has a length spanning substantially the entire length of the grinding fine white roller body 84 ( Figure 10 ).

[0092] refer to Figure 10 , 11 The internal mechanism of the resistance body device 36 will be described.

[0093] The cover body 36a of the resistance body device 36 is fixed on the pillar 33 on which the above-mentioned bran rem...

Embodiment 3

[0103] Figure 13 , 14 Main part of Example 3 is shown. The overall structure of the grinding type vertical rice miller 1 in this embodiment, the structure of the grain supply part, the grinding mill part, the grain discharge part, the bran collection part, and the main body base part are the same as the above-mentioned embodiment 1. The same symbols, and the reference description.

[0104] Compared with Example 2, Example 3 is characterized in that the urging structure of the urging device 85 is an air pressure structure in the resistance body device 36 and the external air intake structure.

[0105] 〔Resistance body device〕

[0106] As in the case of the first embodiment, the resistance body device 36 is long in the axial direction of the main shaft 19 and has a length spanning substantially the entire length of the polished white roller body 84 .

[0107] refer to Figure 13 , 14 The internal mechanism of the resistance body device 36 will be described.

[0108] A co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com