Solenoid valve assembly for a seat of a vehicle

A solenoid valve assembly and armature technology, applied in vehicle seats, vehicle components, special positions of vehicles, etc., can solve the problems of reducing plunger acceleration, delaying plunger movement, and weakening plunger movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

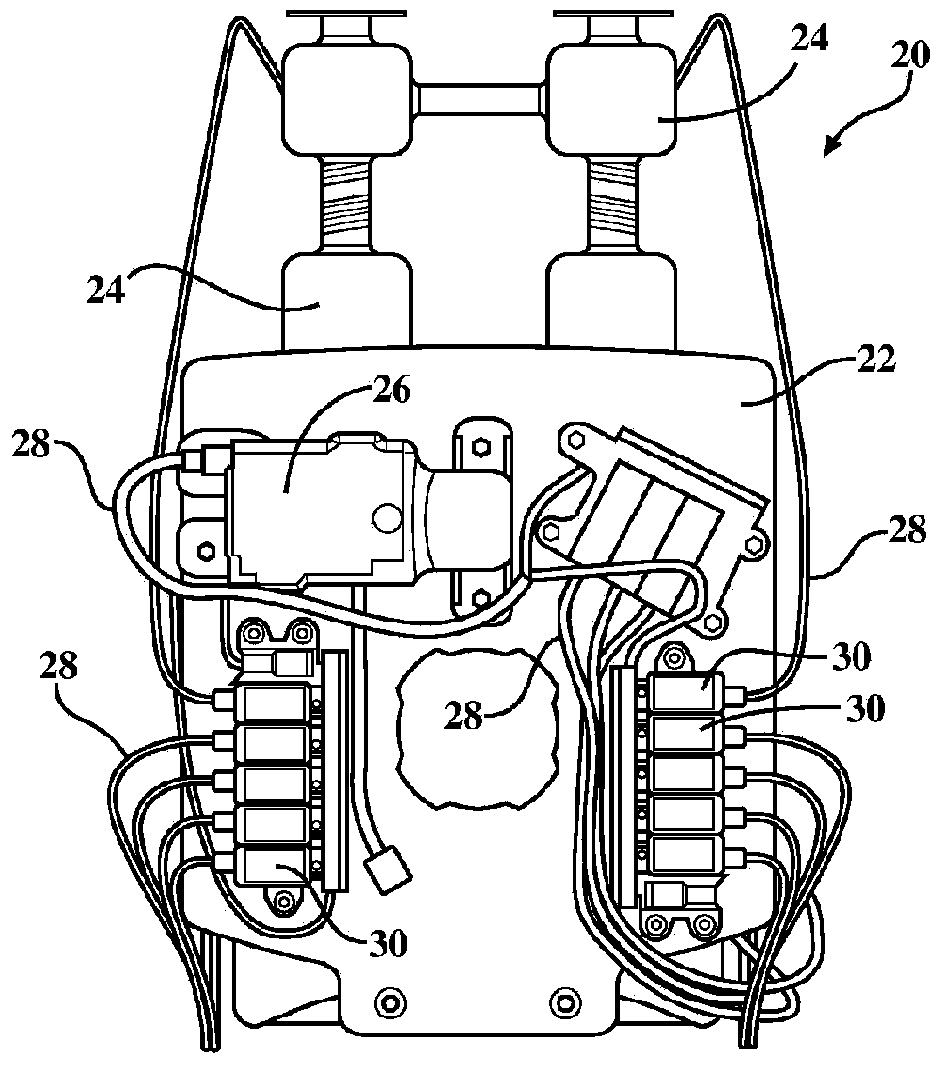

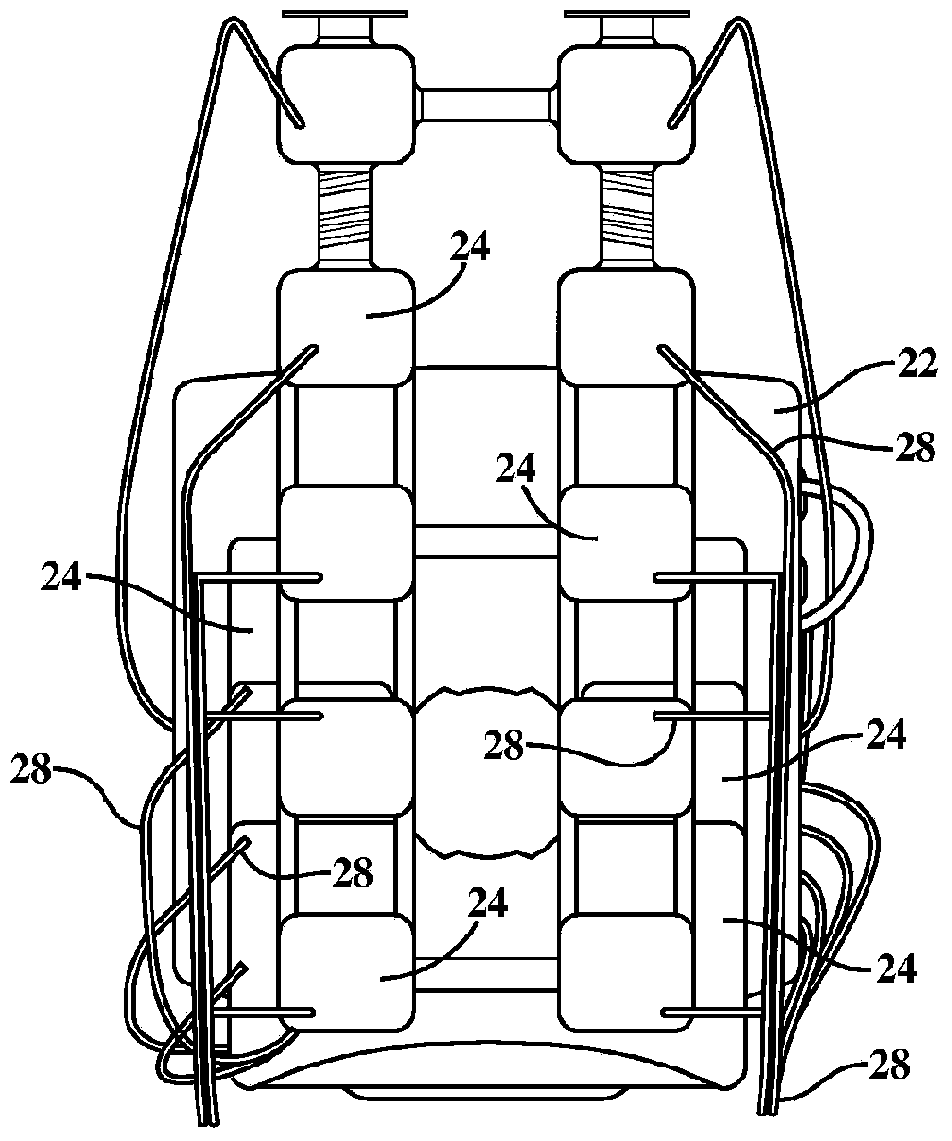

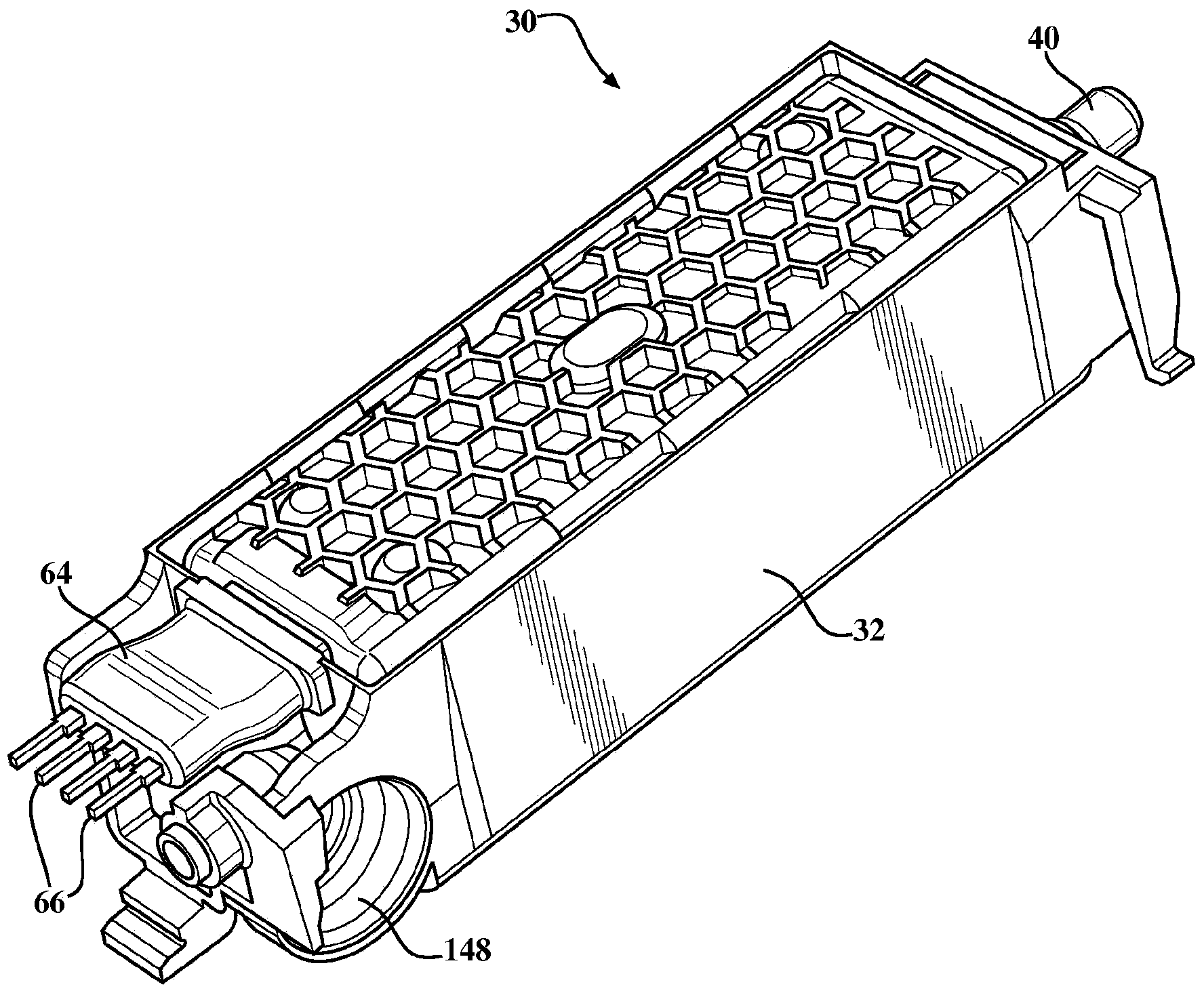

[0021] Referring to the drawings, in which like reference numerals denote like or corresponding parts throughout the several views, figure 1 A seat assembly 20 for a vehicle (not shown) is generally shown.

[0022] also refer to figure 2 , the seat assembly 20 includes a seat frame 22 . The seat assembly 20 may include a seat with a seat frame 22 disposed within the seat. More specifically, the seat may include a back for supporting the user's back and a bottom for supporting the user's legs. The seat frame 22 may be disposed within the back and / or bottom of the seat. It should be understood that the seat frame 22 may be of any suitable configuration.

[0023] Seat assembly 20 includes an air bag 24 coupled to seat frame 22 . The airbag defines an expanded position when the airbag 24 is inflated and a deflated position when the airbag 24 is deflated. It should be understood that the balloon 24 may be partially inflated and partially deflated. Thus, the expanded positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com