Noodle making device

A noodle making device and noodle technology, applied in the direction of dough extruder, etc., can solve the problems of waste of resources, slow speed of noodles, fast speed of bread machine, etc., and achieve the effect of less space, increased torque and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

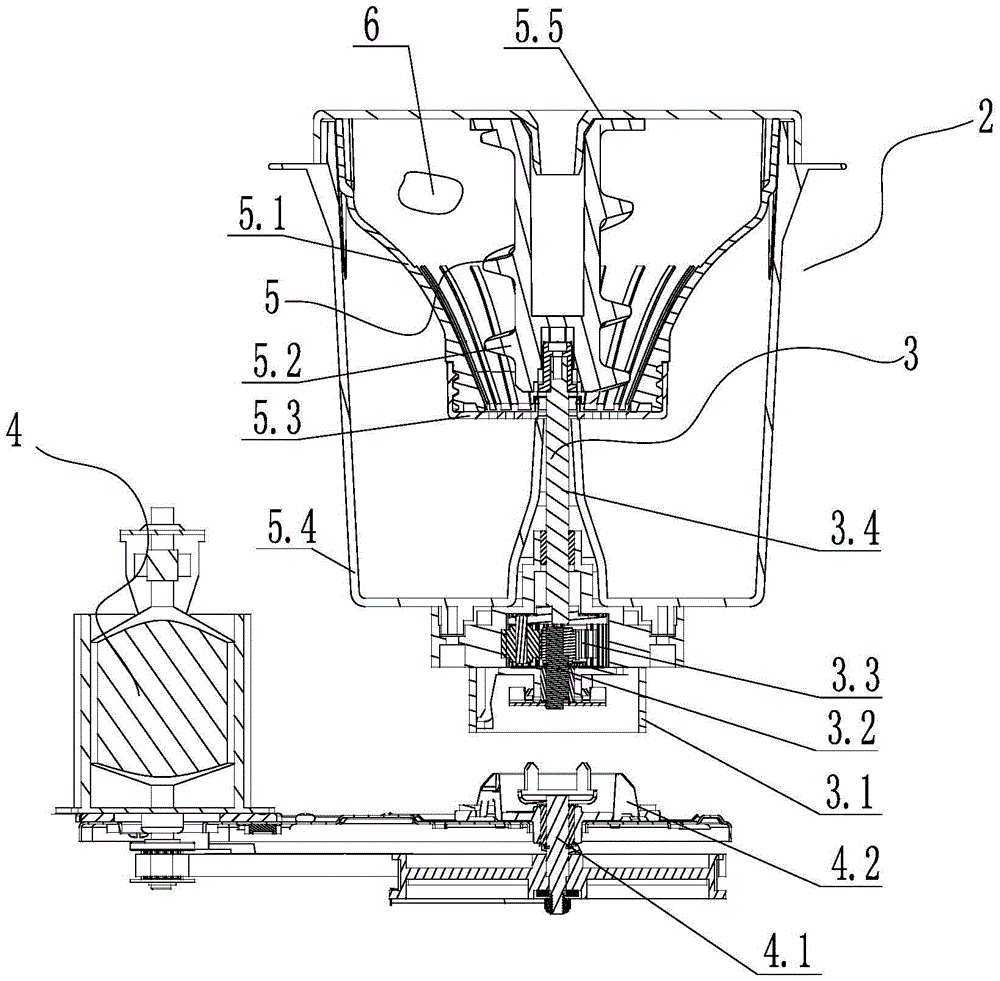

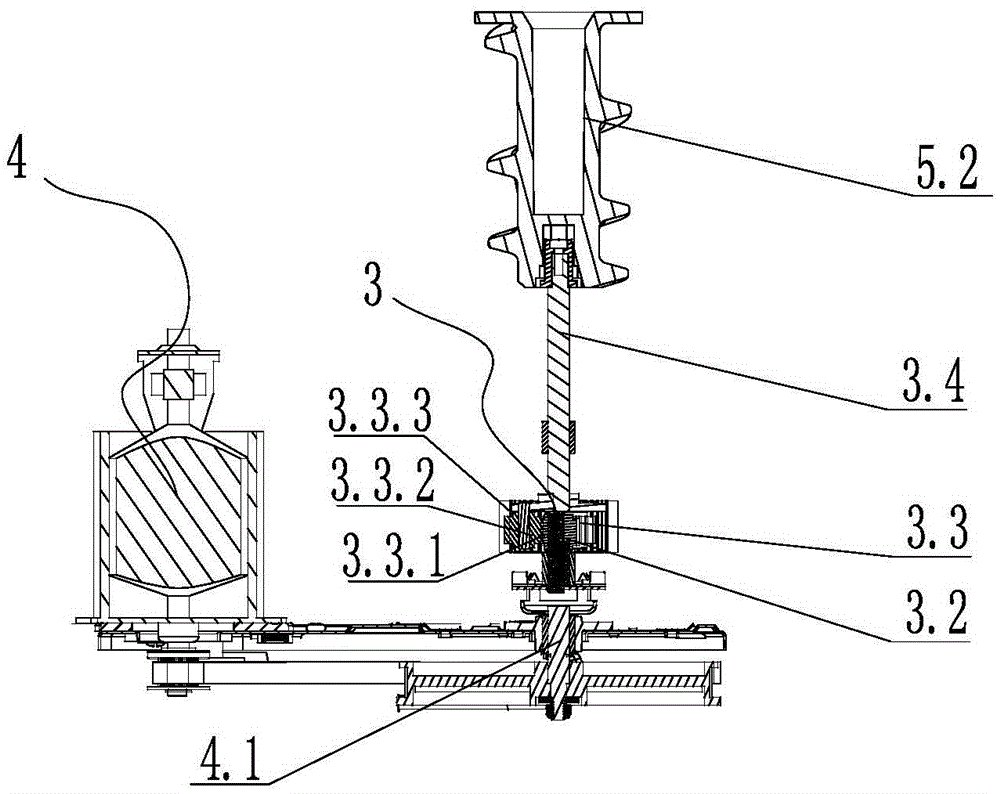

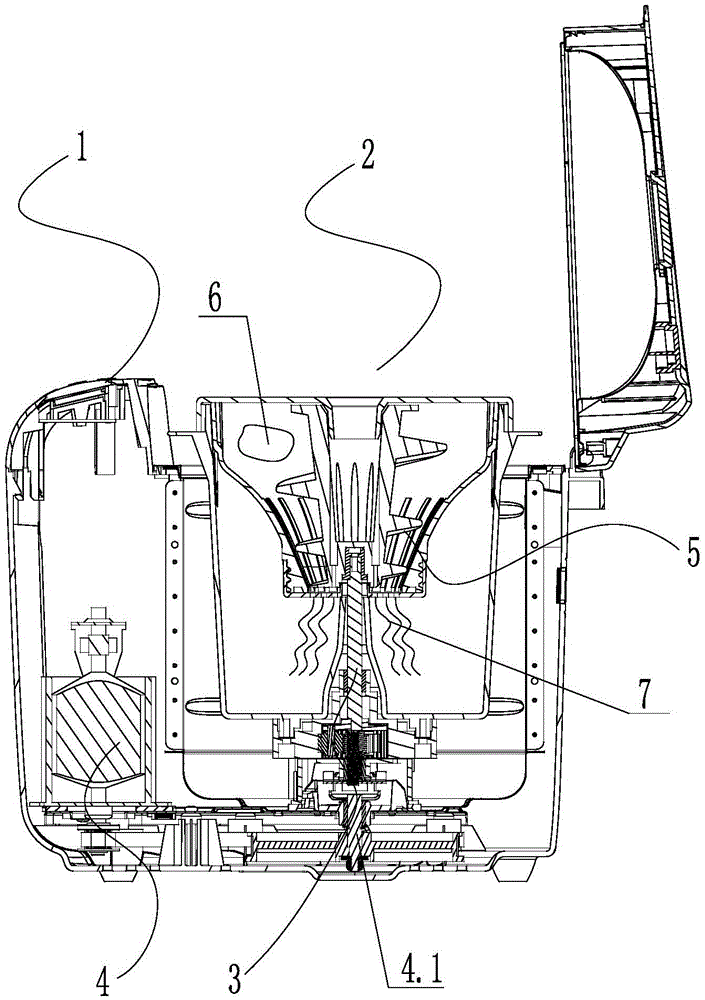

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0051] like Figure 1 to Figure 6 Shown is one embodiment of the invention. In this embodiment, the noodle making device 2 includes a connection deceleration assembly 3 detachably connected to the driving mechanism 4 of the bread machine 1, the connection deceleration assembly 3 serves to reduce the output speed and increase the output torque; and The noodle forming assembly 5 whose axis is parallel to or coaxial with the fork shaft 4.1 of the drive mechanism 4 is used to connect with the deceleration assembly 3 to make noodles 7 .

[0052] like figure 1 , figure 2 and image 3 As shown, in this embodiment, the connection deceleration assembly 3 includes:

[0053] bucket seat 3.1;

[0054] Stirring shaft 3.2 fixedly connected with bucket seat 3.1;

[0055] The stirring shaft 3.2 in the bucket seat 3.1 is detachably connected with the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com