Full-automatic sausage casing surface hair removal equipment

A fully automatic, casing technology, used in sausage casings, processing animal intestines, slaughtering and other directions, can solve the problems of casings that do not meet food hygiene standards, difficult to remove completely, and labor-intensive, etc., to ensure complete removal and work efficiency. High, improve the effect of rapid feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

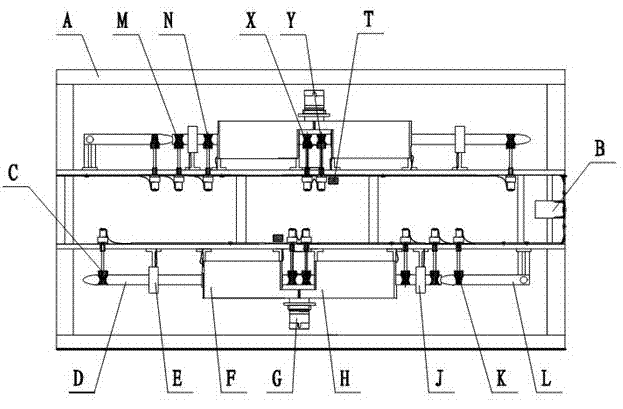

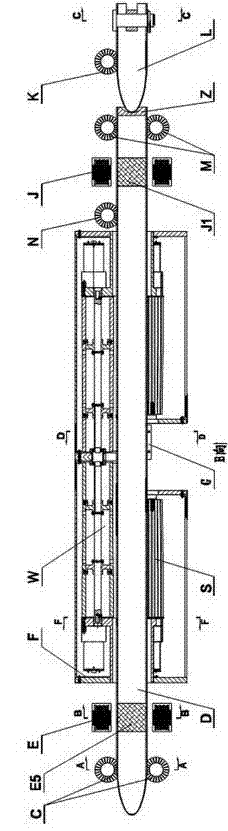

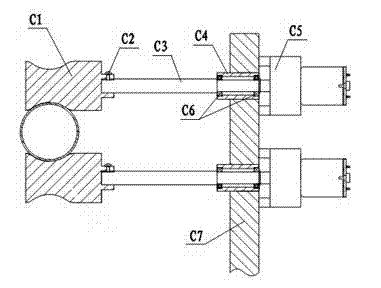

[0029] see Figure 1~Figure 13 A fully automatic casing surface hair removal equipment, including base A, equipment controller B, front feed device C, suspension shaft D, front magnetic support device E, primary circumferential drive device F, razor servo control device G , Two-stage circumferential drive device H, rear-end magnetic support device J, front-end differential feed drive device X, rear-end differential feed drive device Y, single-side same-speed feed drive device N, rear-end feed device M, one-side same-speed feeding drive device K for tail material, L storage device for tail material, combined sensor T, roller drive device W, roller drive device R, roller drive device S, and through-axis top block Z.

[0030] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com