Method for calibrating roundness of large-diameter thick-wall round pipe

A large-diameter, round tube technology, applied in the field of rounding of large-diameter thick-walled round tubes, can solve the problems of increased scrap rate, time-consuming and laborious, and inability to meet the accuracy requirements of the round tube, ensuring the accuracy of the round tube and ensuring correct recovery. , the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

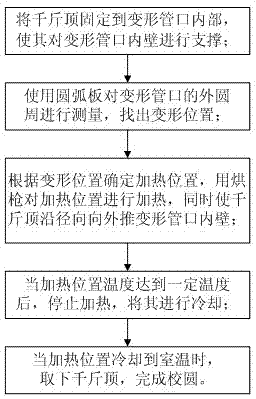

[0020] Such as figure 1 Shown is a method for adjusting the circle of a large-diameter thick-walled circular pipe, the method comprising the following steps:

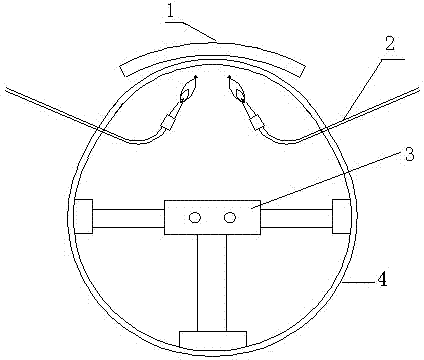

[0021] (1) Fix the jack inside the deformed nozzle to support the inner wall of the deformed nozzle. By using a jack to support the inside of the nozzle, there is a radially outward force on the inner wall of the nozzle. The jack can correct the deformation position when the stress is released at the deformation position of the nozzle.

[0022] (2) Use the arc plate to measure the outer circumference of the deformed nozzle to find out the deformed position. Specifically, the diameter of the arc plate is equal to the diameter of the outer wall of the circular tube. By sequentially measuring the outer circumference of the deformed nozzle with the arc plate, the position that does not match the diameter of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com