Hopper anti-blocking device

An anti-blocking and silo technology, applied in the direction of packaging, transportation, packaging, containers, etc., can solve the problems of unfavorable transportation, easy agglomeration and blockage of raw material silos, and achieve the effect of ensuring fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

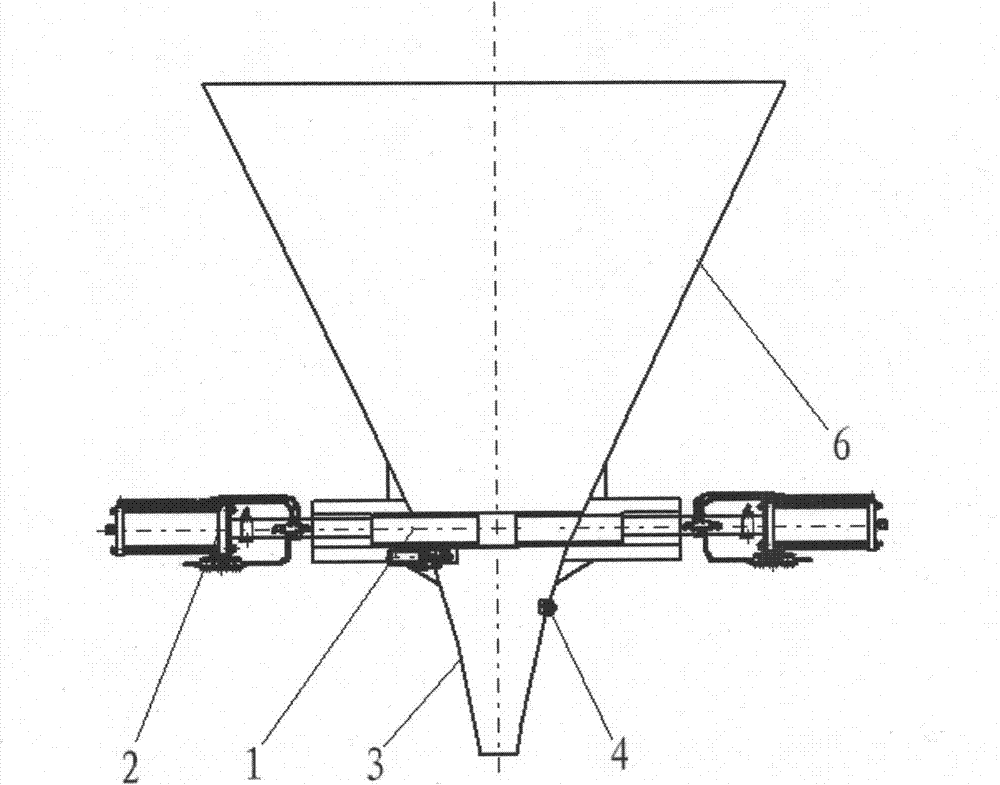

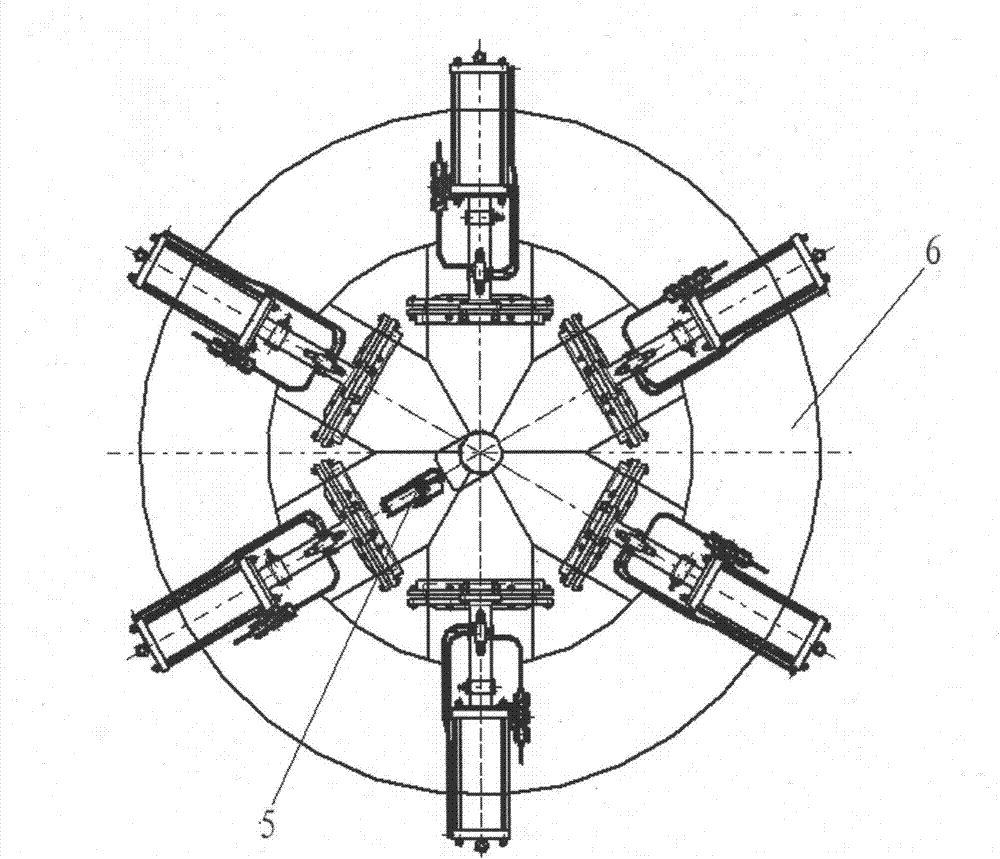

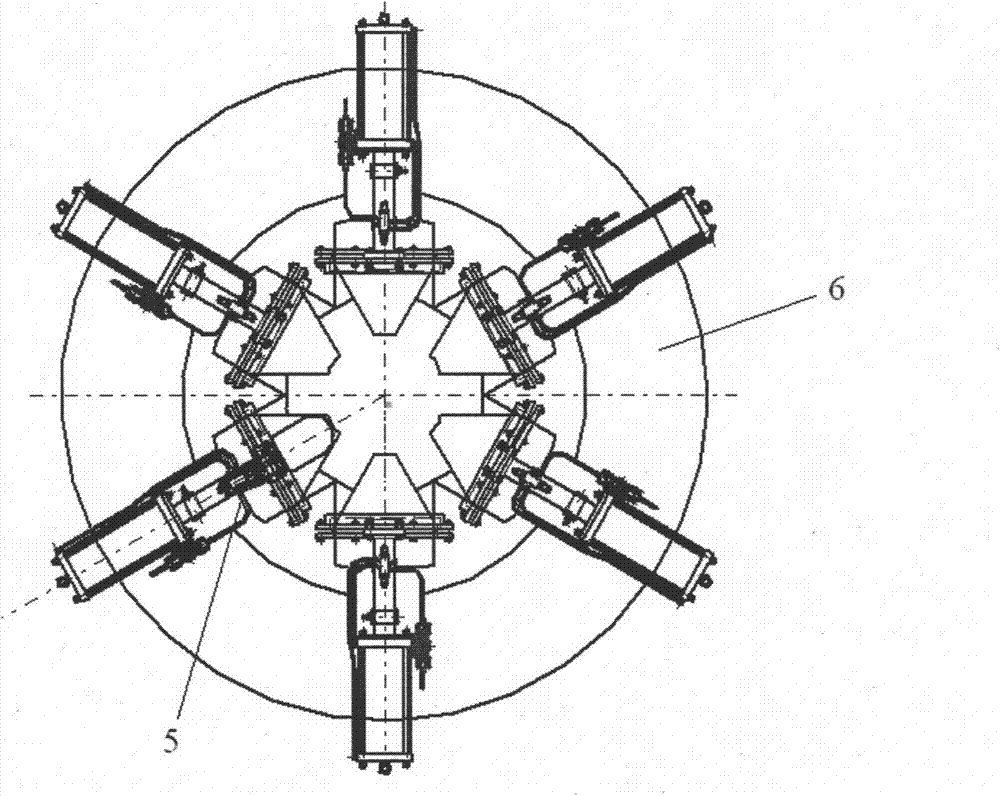

[0012] Such as Figure 1-2 As shown, the structure schematic diagram of the silo anti-blocking device provided by the present invention includes an intermediate silo 3 communicated with the raw material silo 6, and the intermediate silo 3 is provided with a sensor 4; between the raw material silo 6 and the intermediate silo 3 There is at least one set of anti-blocking components, each set of anti-blocking components includes pneumatic / electric actuator 2, control regulating valve 1, the valve plate of control regulating valve 1 is connected with the connecting rod of pneumatic / electric actuator 2, and is executed through pneumatic / electric The device 2 opens or closes the control regulating valve 1; the lower part of the control regulating valve 1 is provided with a compound gate valve 5, which is fixed on the bottom of the control regulating valve 1 valve plate.

[0013] Use the control regulating valve 1 to open or close the valve (not all shut off) from all directions throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com