Accumulation mechanism of accumulation type conveyor

A technology of accumulating and releasing conveyors and driving motors, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of equipment stability, motor energy consumption, and high maintenance costs, so as to reduce maintenance costs and save money. Energy, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

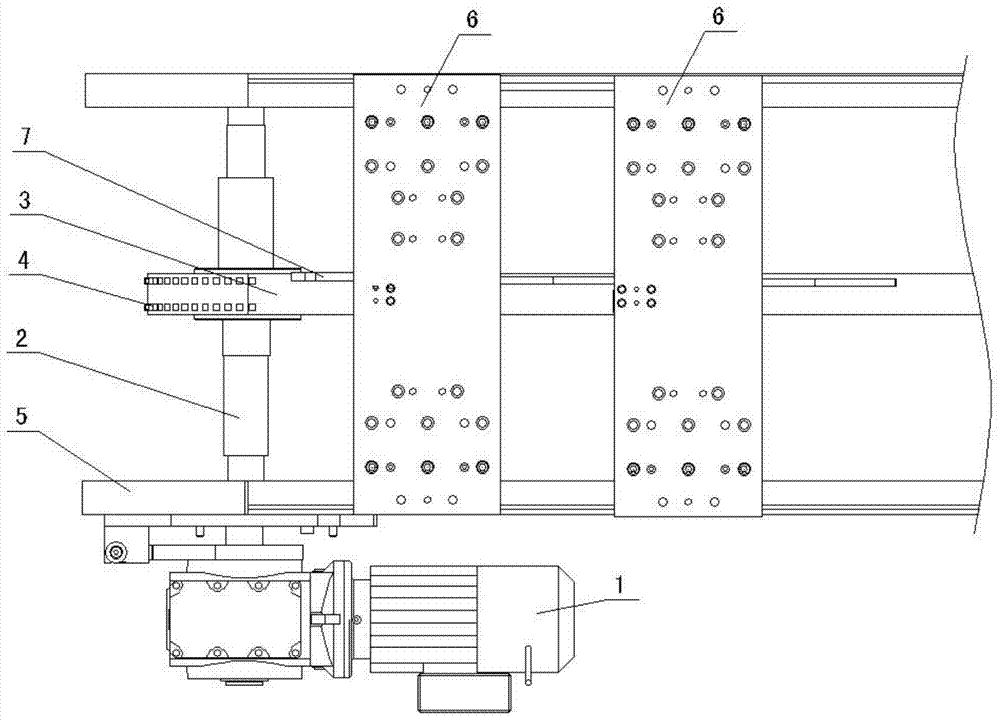

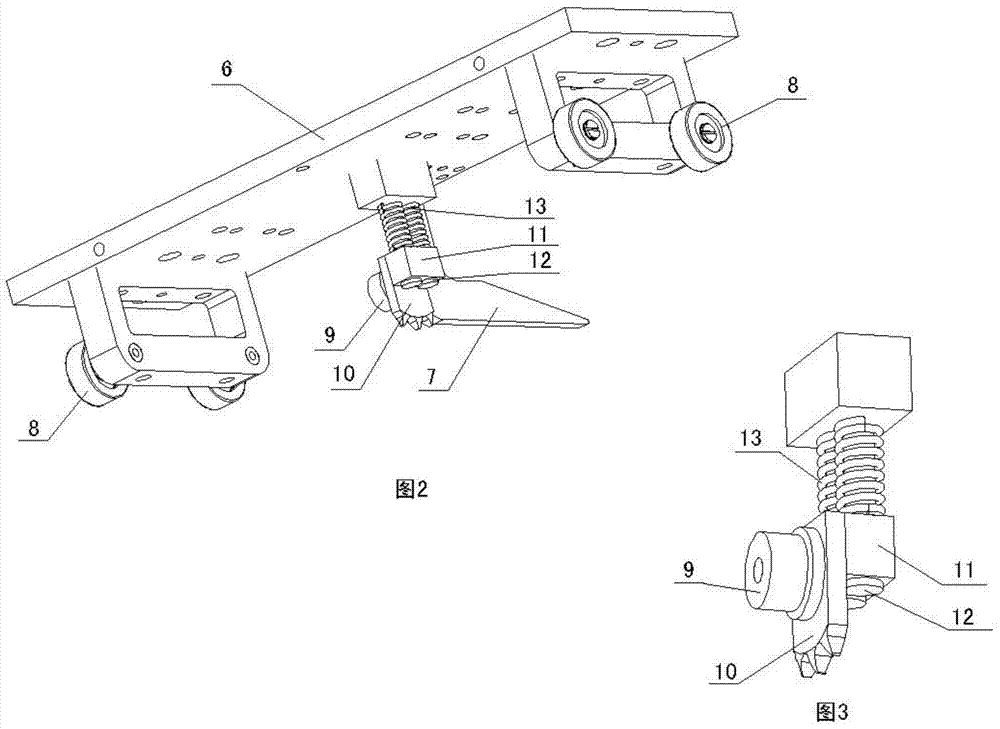

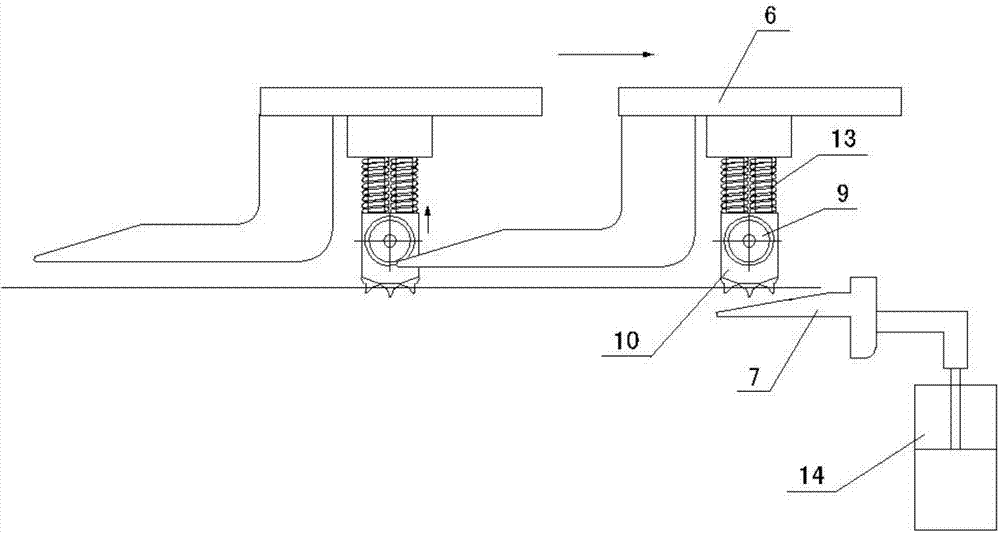

[0016] The structural form of the accumulation mechanism of the accumulation type conveyor in the present embodiment is:

[0017] Labels in the figure: 1 driving motor, 2 transmission shaft, 3 endless chain, 4 transmission sprocket, 5 track bed, 6 pallet trolley, 7 wedge-shaped pallet, 8 roller, 9 rotating wheel, 10 side vertical tooth plate, 11 Slide block, 12 sliding posts, 13 springs, 14 stop cylinders, 6a front pallet dolly, 6b rear pallet dolly, 7a front car wedge-shaped clamping plate, 9b rear pallet dolly's rotating wheel.

[0018] Such as figure 1 As shown, the drive motor 1 is fixedly installed on the rail bed 5, and the drive sprocket 4 fixed on the drive shaft 2 is driven by the drive motor 1 to rotate, and the drive sprocket 4 is driven by the drive sprocket 4 and is arranged on the endless chain 3 to circulate.

[0019] Such as figure 1 , figure 2 and image 3 As shown, the pallet trolley 6 is supported by rollers 8, and the rollers 8 are distributed at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com