Matrix material suction distributor

A dispenser, matrix technology, applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., can solve problems such as non-conformity and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

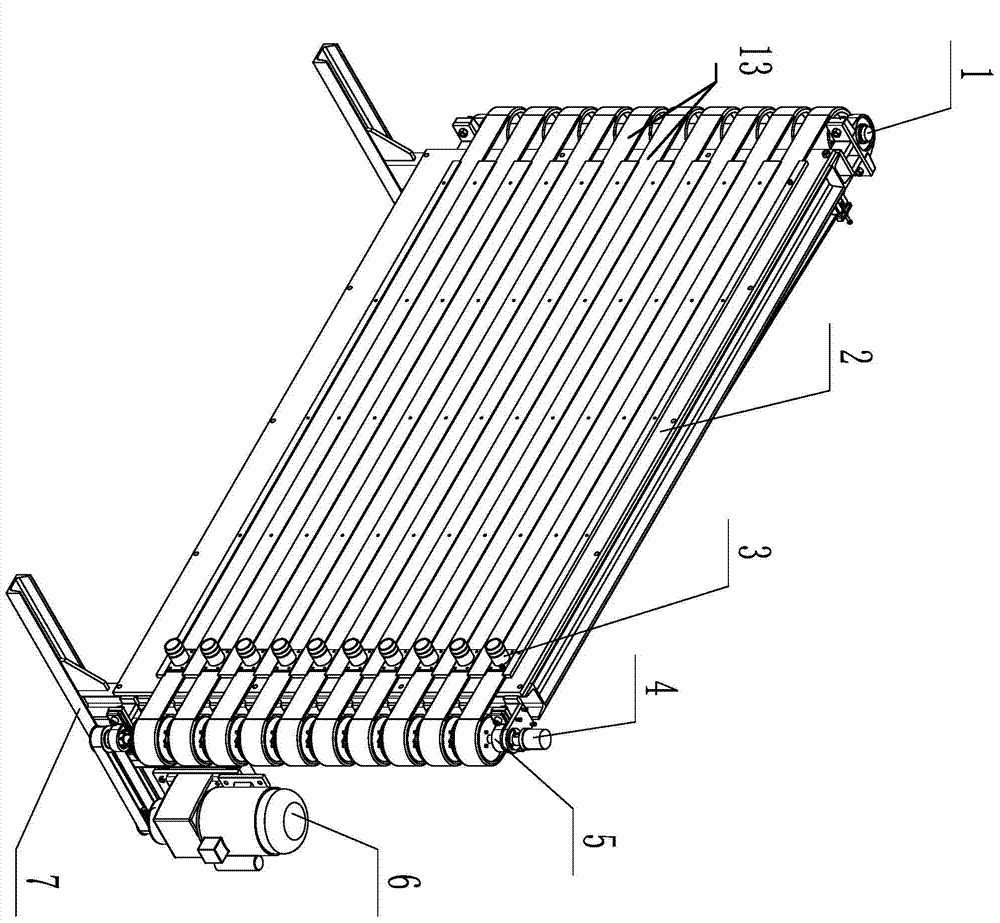

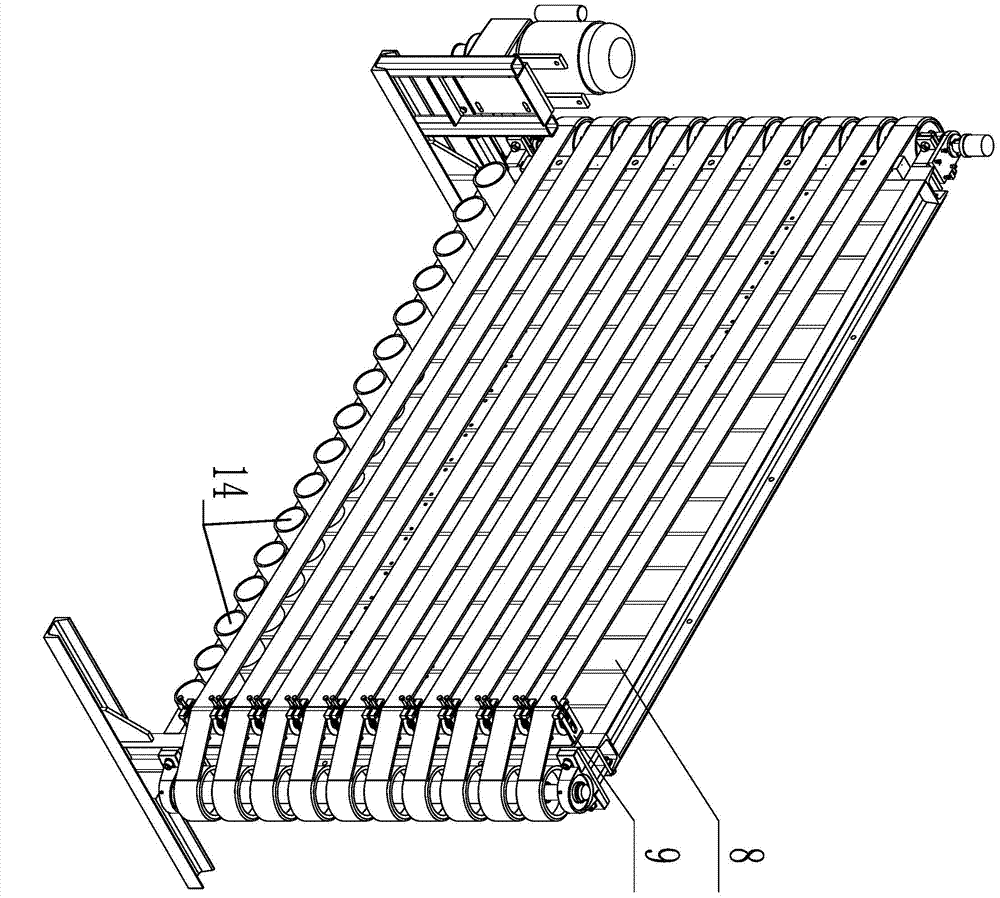

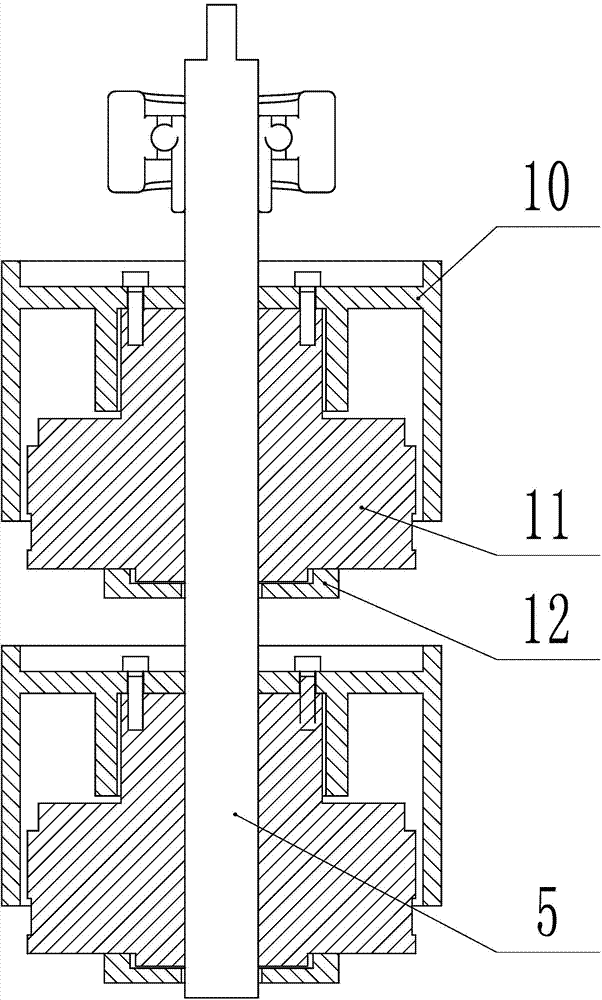

[0013] like Figure 1-5 As shown, the present invention includes a flat pulley embedded electromagnetic clutch structure, a flat belt self-sealing discharge port structure, a modular assembly of the material distribution box, and the positioning of the position encoder of the feeding port. Both sides of the frame 7 are provided with a driving shaft 5 and a driven shaft 1, a flat pulley 10 is arranged on the driving shaft and the driven shaft at intervals, and a flat belt 13 is arranged at intervals around the flat pulley in the horizontal direction. There is a panel 2 and a material distribution box 8 between the moving shafts. Each flat belt is provided with a discharge port 3 connected to the machine material barrel. The panel is located on one side of the material discharge port. The splicing structure, the bottom of each strip groove is provided with a feeding port 14 connected to the silo, and the horizontal and vertical panels are provided with through holes 15 matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com