A centralized treatment method and device for kitchen waste and drainage

A kitchen garbage and centralized treatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to reduce workload, protect the environment, and relieve traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

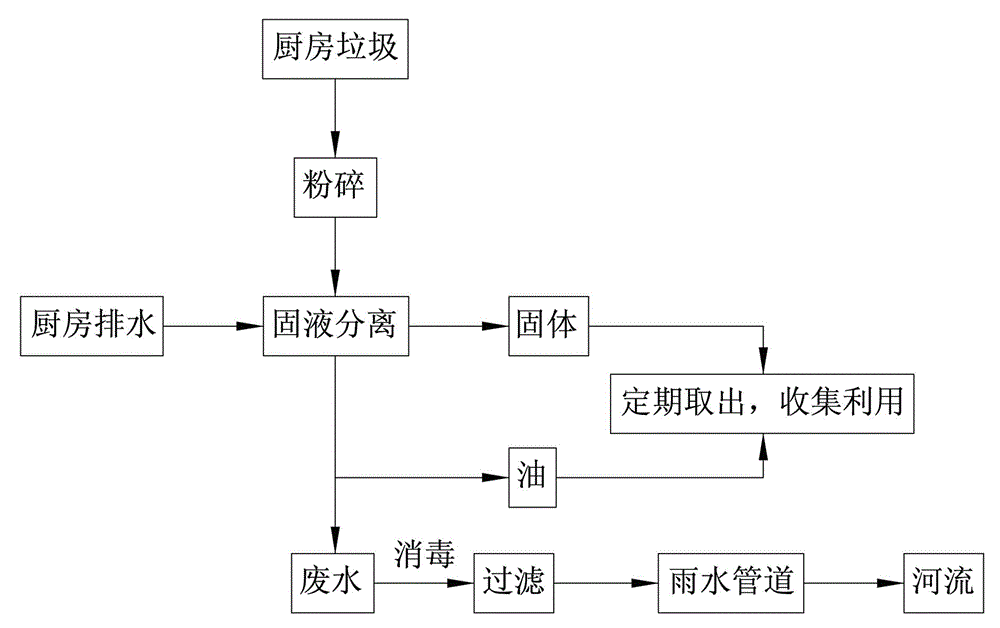

[0044] see figure 1 , the centralized treatment method of kitchen garbage and drainage of the present invention, comprises the following steps:

[0045] 1) Collect the sewage discharged from the kitchen and the crushed kitchen waste, filter it immediately, and separate the solid waste from the liquid;

[0046] 2) For the separated liquid, the separation of oil and water is realized according to the difference in specific gravity of oil and water;

[0047] 3) For the waste water after oil-water separation, first carry out disinfection treatment, and then perform a second filtration to separate the soluble fine solid particles in the sewage from the liquid again;

[0048] 4) After further advanced treatment, the sewage after the second filtration treatment is discharged or reused up to the standard.

Embodiment 2

[0050] The centralized treatment method for kitchen waste and drainage in this embodiment differs from that in Embodiment 1 in that: the sewage is further treated in depth by adopting the ecological treatment method of surface greening: making full use of the greening of the community, and adopting shallow ditches for filtering on the surface. The bottom of the ditch and the wall of the ditch are provided with a water-resisting layer, and the filling layer, the filter layer, and the covering soil layer are successively arranged in the ditch from bottom to top. Substances such as phosphorus are removed, and osmotic filtration is performed at the same time.

Embodiment 3

[0052] The centralized treatment method for kitchen garbage and drainage in this embodiment is different from that in Embodiment 1 or Embodiment 2 in that: the advanced treatment includes the step of filtering sewage by using a filter pipe, and the filter pipe is divided into sections Fill the filter material, follow the direction of the filter pipe, and the pore distribution of the filter material filled in sections is that the water inlet end is large and the water outlet end is small, and nitrogen-loving and phosphorus-loving microorganisms are put in at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com