A kind of asphalt mixture for suppressing reflective cracks of pavement and its preparation method and application

A technology of asphalt mixture and reflective cracks, which is applied in the field of building materials, can solve the problems of increasing the cost of renovation projects in purchase prices, restricting urban road renovation projects, etc., achieving good economic and environmental benefits, and suppressing reflective cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides an asphalt mixture for suppressing reflective cracks on the road surface. The raw materials used are as follows:

[0031] Aggregate: Coarse aggregate and fine aggregate are limestone, the nominal maximum particle size is 19mm, coarse aggregate and fine aggregate account for 76.2% and 12.5% of the mass of the mixture respectively;

[0032] Filler: limestone powder, accounting for 4.2% of the mass of the mixture;

[0033] Fiber stabilizer: lignin fiber, with an average length of about 4mm, accounting for 0.3% of the mass of the mixture;

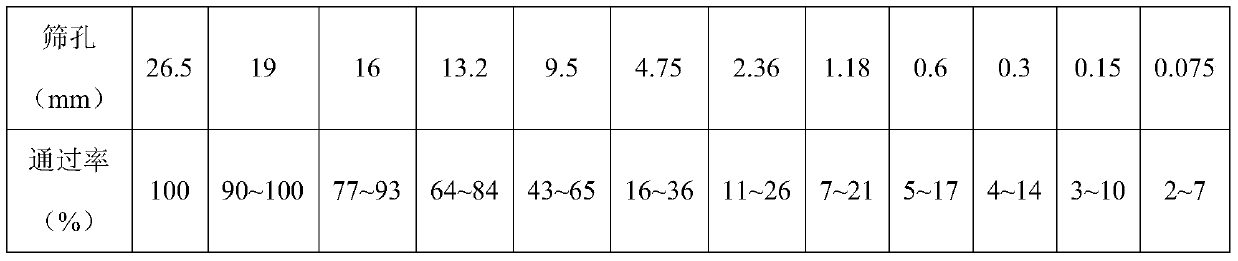

[0034] The ore grading is:

[0035] Sieve hole (mm)

26.5

19

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate(%)

100.0

95.1

81.6

65.5

45.1

19.7

14.6

11.4

8.9

7.5

6.7

5.9

[0036] High-viscosity asphalt binder: accounting for 6.5% of the mass of the mixture, modified from Tepco 70# asphalt 77.3%, 60-80 mesh waste...

Embodiment 2

[0042] Aggregate: Coarse aggregate and fine aggregate are limestone, the nominal maximum particle size is 19mm, coarse aggregate and fine aggregate account for 72.9% and 14.9% of the mass of the mixture respectively;

[0043] Filler: limestone powder, accounting for 5.1% of the mass of the mixture;

[0044] Fiber stabilizer: lignin fiber, with an average length of about 5mm, accounting for 0.4% of the mass of the mixture;

[0045] The ore grading is:

[0046] Sieve hole (mm)

26.5

19

16

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing rate(%)

100.0

95.2

82.1

66.4

46.1

21.6

16.1

12.4

9.4

7.9

6.9

6.0

[0047] High-viscosity asphalt binder: accounting for 6.7% of the mass of the mixture, composed of 77.1% of Korean SK70# asphalt, 14.9% of 60-80 mesh waste rubber powder, 2‰ of industrial grade sulfur, 3.8% of warm mixing agent and high-viscosity asphalt modifier 4% composition, among wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com