A waste tire cracking and discharging process and equipment

A technology for waste tires and processes, which can be used in feeding devices, petroleum industry, fibrous fillers, etc., and can solve problems such as increasing production costs, production processes, and difficulty in discharging materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

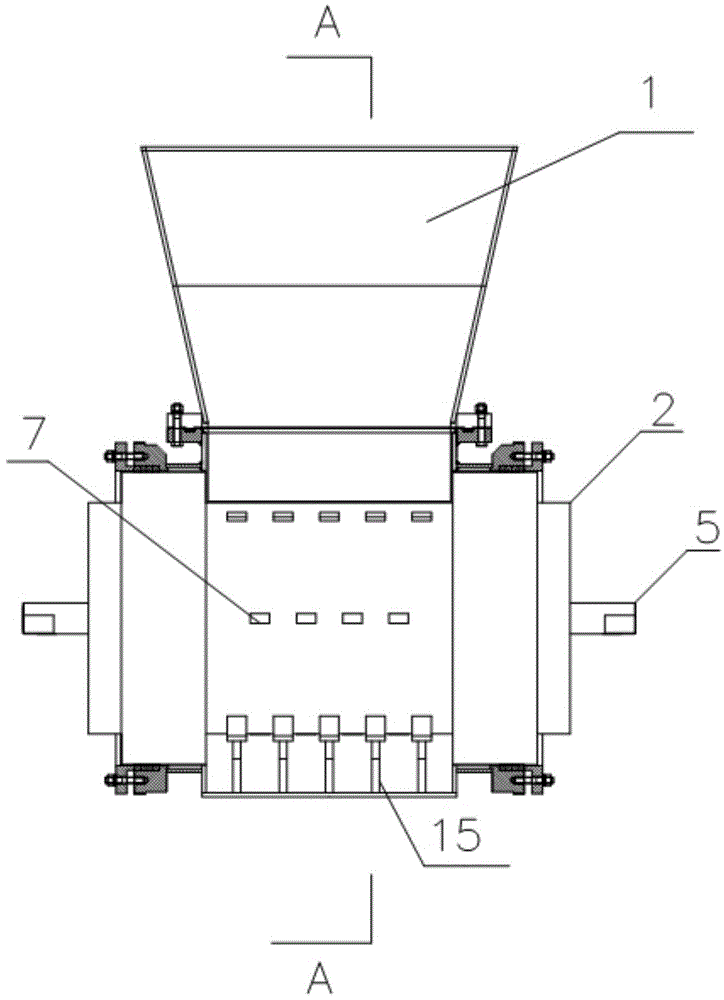

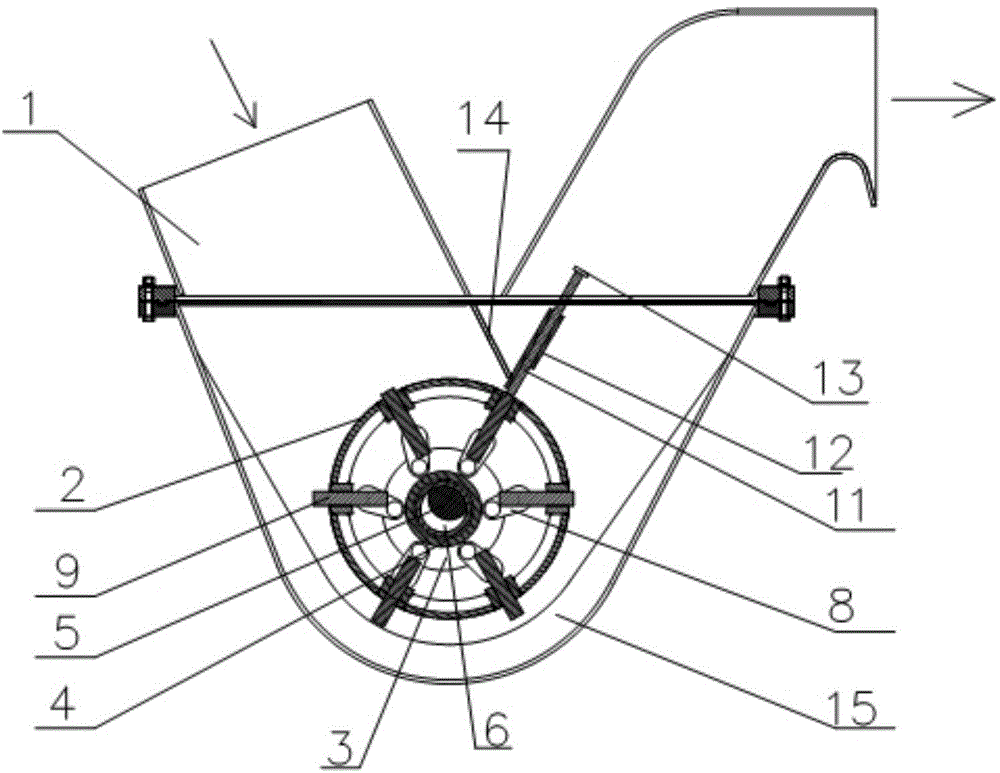

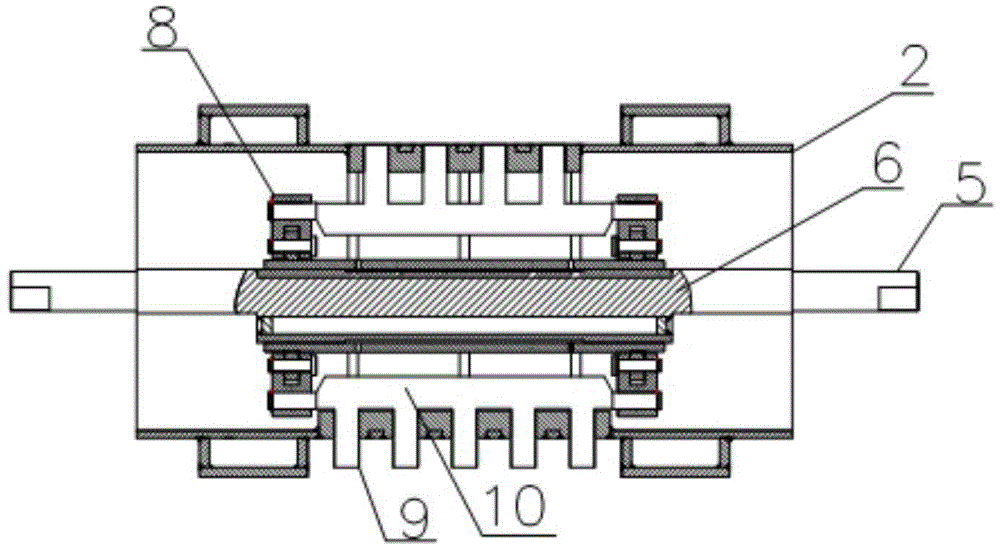

[0024] A kind of waste tire cracking and discharging equipment, including a silo, which is equipped with a discharging mechanism, a sealing device and a baffle; There is a rotating sleeve in between; the eccentric shaft is composed of shaft I and shaft II placed in one body; the axis of shaft I is above the axis of shaft II, and the rotating cylinder is concentric with shaft I; the turntable is sleeved at both ends of shaft II and concentric with shaft II There are openings on the rotating cylinder, connecting rods on the rotating disc, and a telescopic rod set movable embedded in the opening between the connecting rods of the two rotating discs; the bottom end of the baffle is connected with a sealing device, and the sealing device and the baffle are arranged on the rotary The telescopic rod on the barrel is the shortest.

[0025] The telescopic rod set includes a telescopic rod and a base for fixing the telescopic rod, the connecting rod is connected with the base, and the t...

Embodiment 2

[0032] A kind of waste tire cracking and discharging equipment, including a silo, which is equipped with a discharging mechanism, a sealing device and a baffle; There is a rotating sleeve in between; the eccentric shaft is composed of shaft I and shaft II placed in one body; the axis of shaft I is above the axis of shaft II, and the rotating cylinder is concentric with shaft I; the turntable is sleeved at both ends of shaft II and concentric with shaft II There are openings on the rotating cylinder, connecting rods on the rotating disc, and a telescopic rod set movable embedded in the opening between the connecting rods of the two rotating discs; the bottom end of the baffle is connected with a sealing device, and the sealing device and the baffle are arranged on the rotary The telescopic rod on the barrel is the shortest.

[0033] The telescopic rod set includes a telescopic rod and a base for fixing the telescopic rod, the connecting rod is connected with the base, and the t...

Embodiment 3

[0042] A kind of waste tire cracking and discharging equipment, including a silo, which is equipped with a discharging mechanism, a sealing device and a baffle; There is a rotating sleeve in between; the eccentric shaft is composed of shaft I and shaft II placed in one body; the axis of shaft I is above the axis of shaft II, and the rotating cylinder is concentric with shaft I; the turntable is sleeved at both ends of shaft II and concentric with shaft II There are openings on the rotating cylinder, connecting rods on the rotating disc, and a telescopic rod set movable embedded in the opening between the connecting rods of the two rotating discs; the bottom end of the baffle is connected with a sealing device, and the sealing device and the baffle are arranged on the rotary The telescopic rod on the barrel is the shortest.

[0043] The telescopic rod set includes a telescopic rod and a base for fixing the telescopic rod, the connecting rod is connected with the base, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com