Main shaft of plastic garbage cracking furnace

A technology for plastic waste and cracking furnaces, which is applied in coking ovens, incinerators, and the preparation of liquid hydrocarbon mixtures, and can solve problems such as large environmental impacts, long time periods, and equipment explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

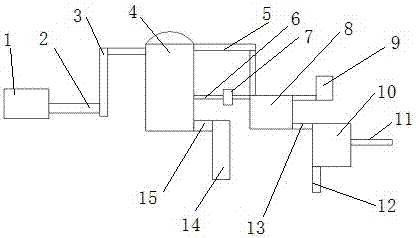

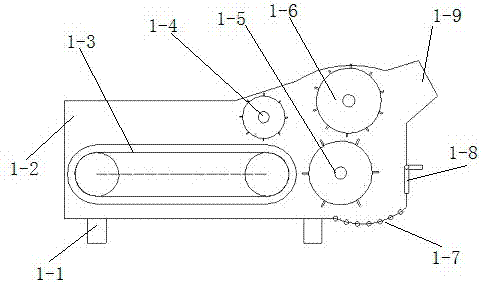

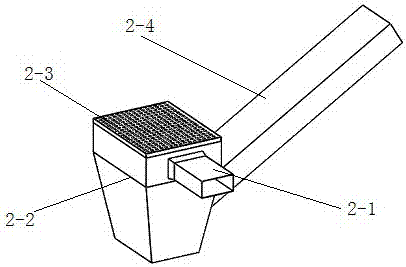

[0042] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1-8 , in this example, a common rack in this industry is selected as the rack 1-1, and the rack 1-1 is installed on the equipment foundation to support and install the entire functional components; the shell 1-1 is made of a steel plate with a thickness of 1 mm 2. Install the shell 1-2 on the frame 1-1; choose the chain conveyor belt commonly used in this industry as the conveyor belt 1-3, install the conveyor belt 1-3 on one end of the frame 1-1, and connect it with the The power and control system are connected, and the plastic waste to be processed can be sent from the feed port of the sorting equipment to the 1-4 of the material; in this example, a hollow cylinder is selected as the main body of the 1-4 of the material, and the two ends Rotating shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com