Plastic garbage treatment system

A technology for plastic waste and treatment systems, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve problems such as equipment not working, equipment explosion, land occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

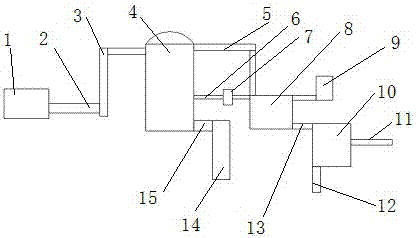

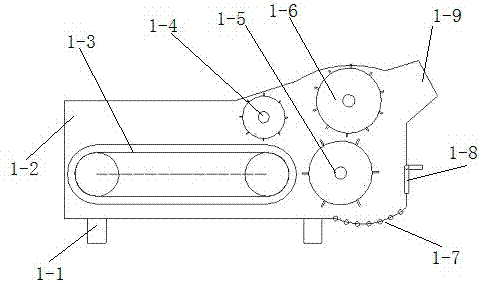

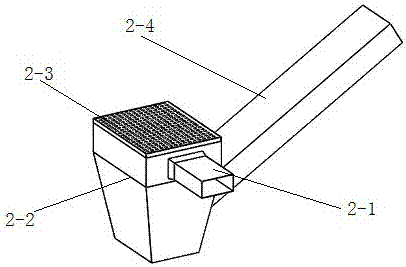

[0042] In order to further illustrate the technical solutions of the present invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings, such as Figure 1-8 , in this example, a rack commonly used in the industry is selected as rack 1-1, and rack 1-1 is installed on the equipment foundation to support and install the entire functional components; a steel plate with a thickness of 1 mm is used to make the shell 1-1 2. Install the shell 1-2 on the frame 1-1; select the chain conveyor belt commonly used in this industry as the conveyor belt 1-3, install the conveyor belt 1-3 on one end of the frame 1-1, and connect it with the The power and control system are connected, which can send the plastic waste to be processed from the feeding port of the sorting equipment to the feeding wheel 1-4; in this example, a hollow cylinder is used as the main body of the feeding wheel 1-4, and the two ends are Set the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com