Fermentation process of neomycin

A fermentation process and neomycin technology are applied in the biological field to achieve the effects of improving titer, improving fermentation production level and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

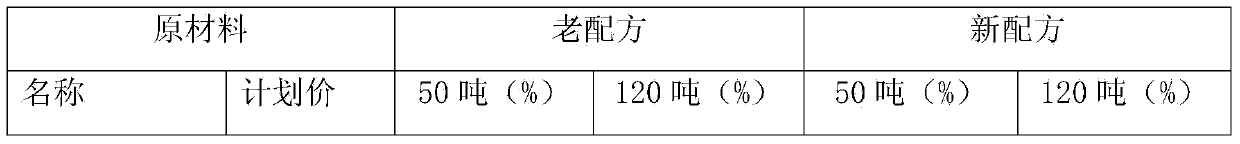

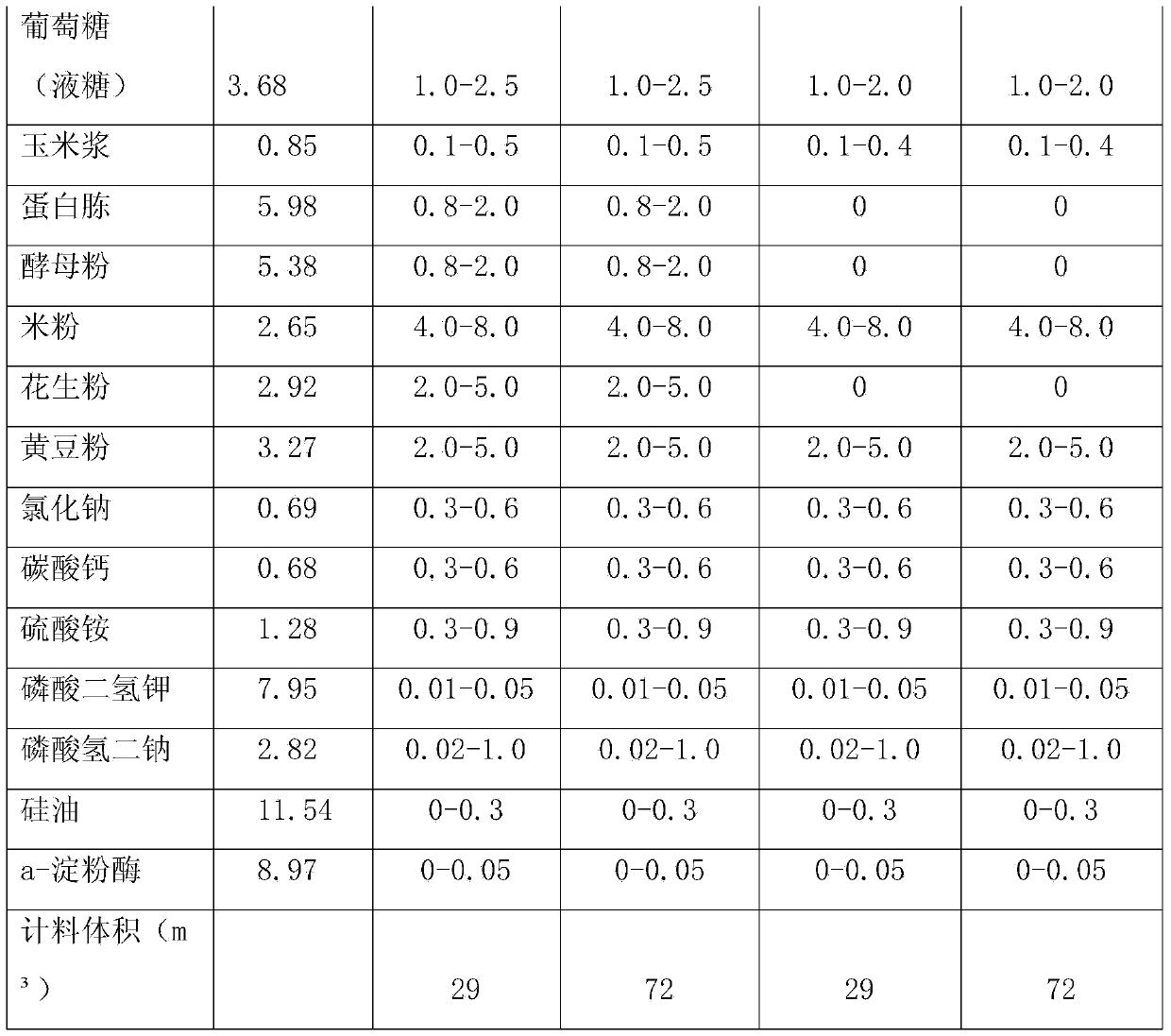

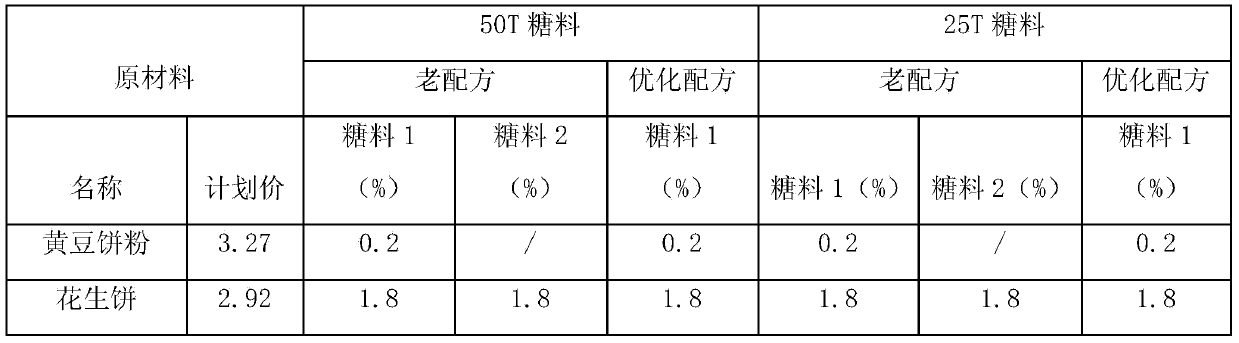

Method used

Image

Examples

Embodiment 1

[0033] 1. Seal the sandy soil spores, dry them, store them at 4°C for 10 days, then place them at 28±2°C for 10 days to prepare the inclined plane spore suspension;

[0034] 2. The slant spore suspension was put into a seed tank with a seed medium set in advance and cultivated for 48 hours to obtain a culture solution. The mass content of soybean powder in the seed tank was 3.3% of the seed medium.

[0035] 3. Send the seed culture liquid that obtains through step 2 into the fermentor that pre-sets fermentation medium to inoculate, wherein the mass content of glucose is 1.0% of the fermentation medium quality, and the mass content of corn steep liquor is 0.18% of the fermentation medium quality %, fermented at 30-35°C to obtain a fermented liquid; after the seed culture liquid enters the fermenter, air is introduced, and the flow rate of the air is controlled to 500 3 / h, control the inlet for 9h; control the air inlet flow rate to 1600m 3 / h, control the access time to 29h, ...

Embodiment 2

[0040] 1. Seal the sandy soil spores, dry them, store them at 0°C for 5 days, then place them at 28±2°C, and cultivate them for 12 days to prepare the inclined plane spore suspension;

[0041] 2. Put the slant spore suspension into a seed tank with a seed medium set in advance and cultivate it for 36 hours to obtain a culture solution. The mass content of soybean powder in the seed tank is 1.3% of the seed medium.

[0042] 3. Put the seed culture solution obtained in step 2 into a fermenter with a pre-set fermentation medium for inoculation, and ferment at 30-35°C to obtain a fermentation solution. After the seed culture solution enters the fermenter, air is introduced to the Air inlet flow control is 680m 3 / h, and pass through for 16h; increase the flow rate of air, and control the flow rate of air flow to 16000m 3 / h, and feed in for 22h, and add sugar; further increase the air intake, and control the air intake flow rate to 3000m 3 / h, and pass through for 42h, and contr...

Embodiment 3

[0047] 1. Seal the sandy soil spores, dry them, store them at 2°C for 7 days, and then culture them at 28±2°C for 8 days to prepare the inclined plane spore suspension;

[0048] 2. Put the slant spore suspension into a seed tank with a seed medium set in advance and cultivate for 40 hours to obtain a culture solution. The mass content of soybean powder in the seed tank is 2.4% of the seed medium.

[0049] 3. Put the seed culture solution obtained in step 2 into a fermenter with a pre-set fermentation medium for inoculation, and ferment at 30-35°C to obtain a fermentation solution. After the seed culture solution enters the fermenter, air is introduced to the Air inlet flow control is 500m 3 / h, and pass through for 30h; increase the flow of air, and control the flow rate of air flow to 1500m 3 / h, and feed in for 30h, and add sugar; further increase the air intake, and control the air intake flow rate to 2800m 3 / h, and pass through for 50h, and control the viscosity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com