The transmission mechanism of the pulsator washing machine with safety protection

A pulsator washing machine and safety protection technology, applied in the field of washing machines, can solve the problems of hanging, low reliability of safety means, bypassing of children, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

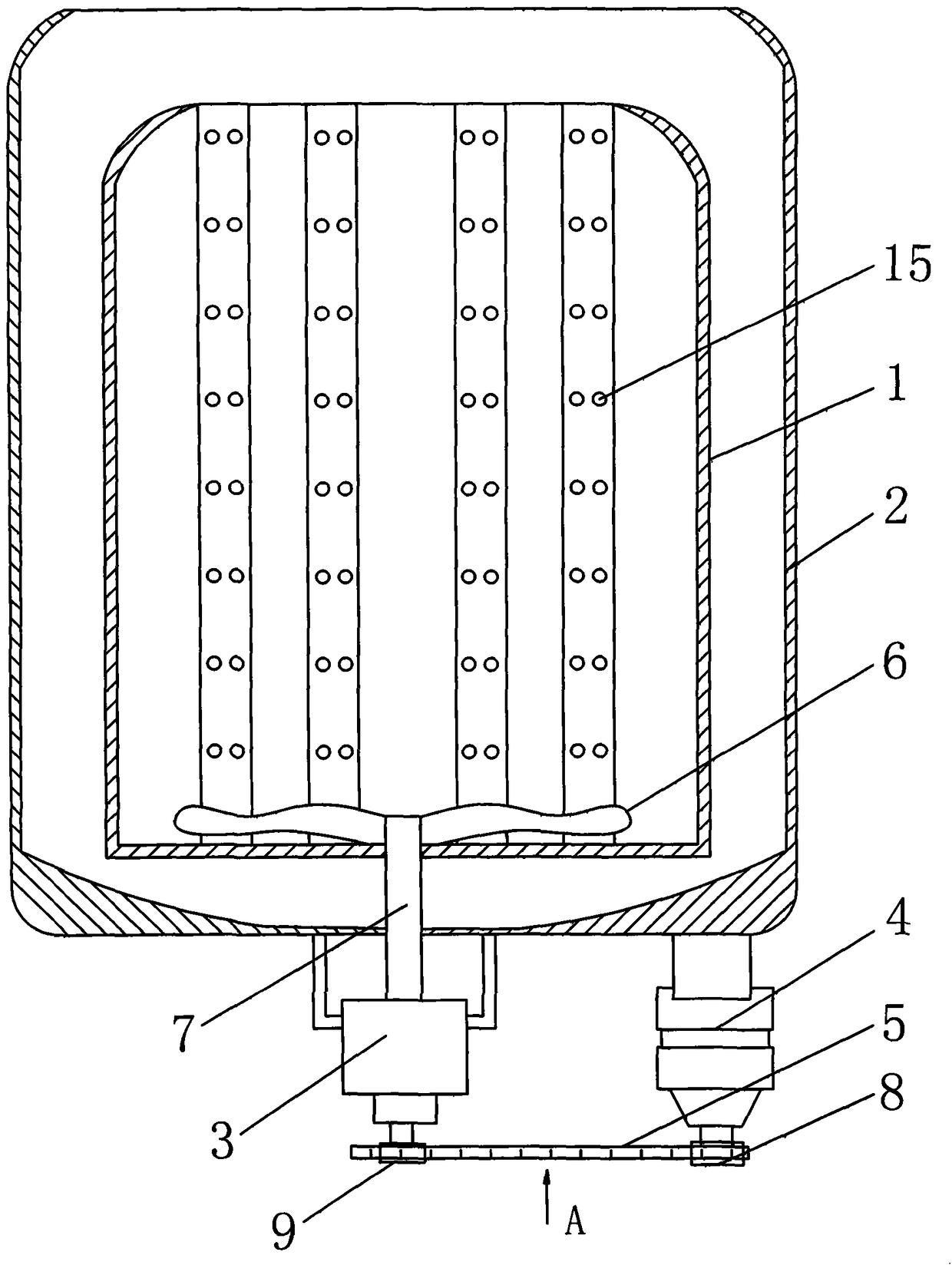

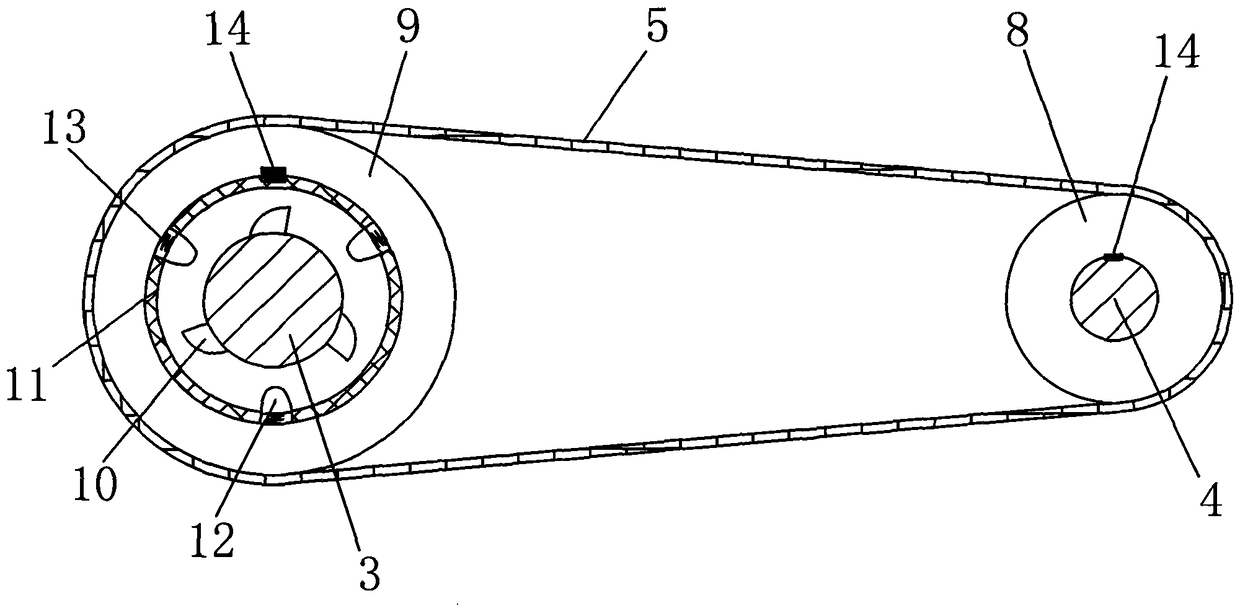

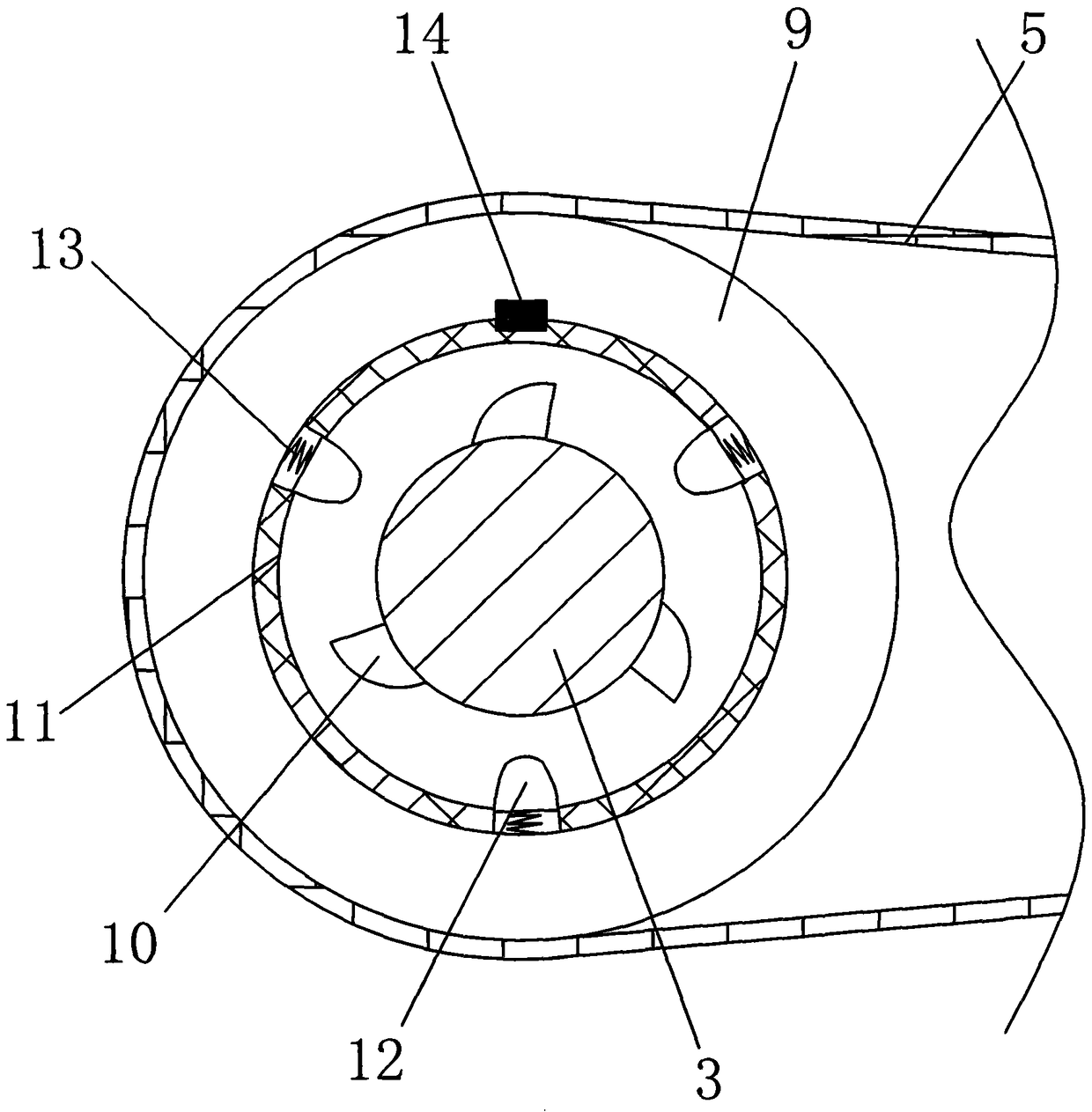

[0015] Such as figure 1 As shown, a safety protection pulsator washing machine transmission mechanism includes an inner cylinder 1, an outer cylinder 2, a clutch 3, a motor 4, a belt 5 and a pulsator 6, and the inner cylinder 1 is set inside the outer cylinder 2 , the clutch 3 and the motor 4 are fixedly installed on the bottom of the outer wall of the outer cylinder 2 through a support, the pulsator 6 is arranged at the bottom of the inner cylinder 1, and the lower end of the rotating shaft 7 of the pulsator 6 passes through the outer cylinder 2 and the clutch The output shafts of 3 are connected; the output shaft of the motor 4 is equipped with a driving pulley 8, and the input shaft of the clutch 3 is equipped with a driven pulley 9, and the driving pulley 8 and the driven pulley 9 are connected and driven by a belt 5. At least one inner ring of the driving pulley 8 and the driven pulley 9 is equipped with an overload protection mechanism;

[0016] In this example, if fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com