Milling machine sprinkler control system and its control method

A control system and milling machine technology, applied in the milling machine control system, milling machine sprinkler control system and its control field, can solve the problems of delaying construction progress, wasting water resources, increasing the number of water additions, etc., to reduce the number of water additions , Improve construction progress and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

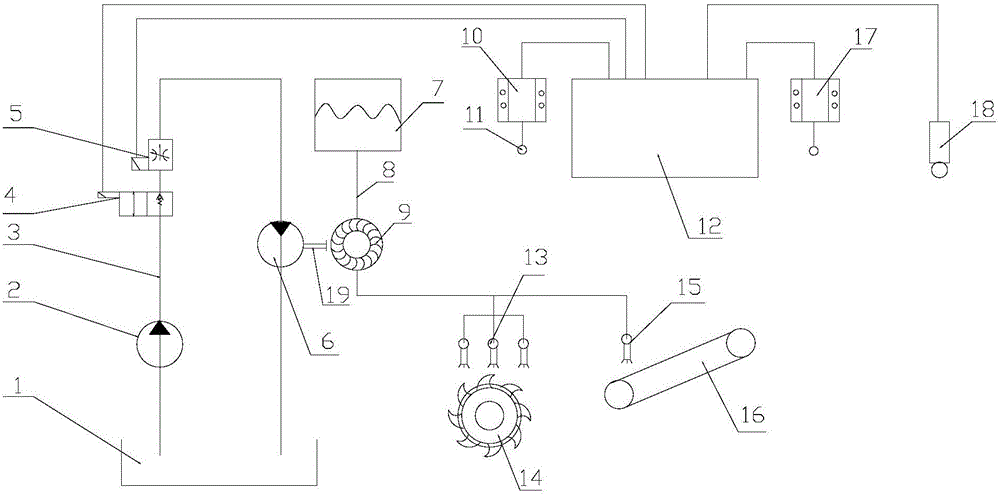

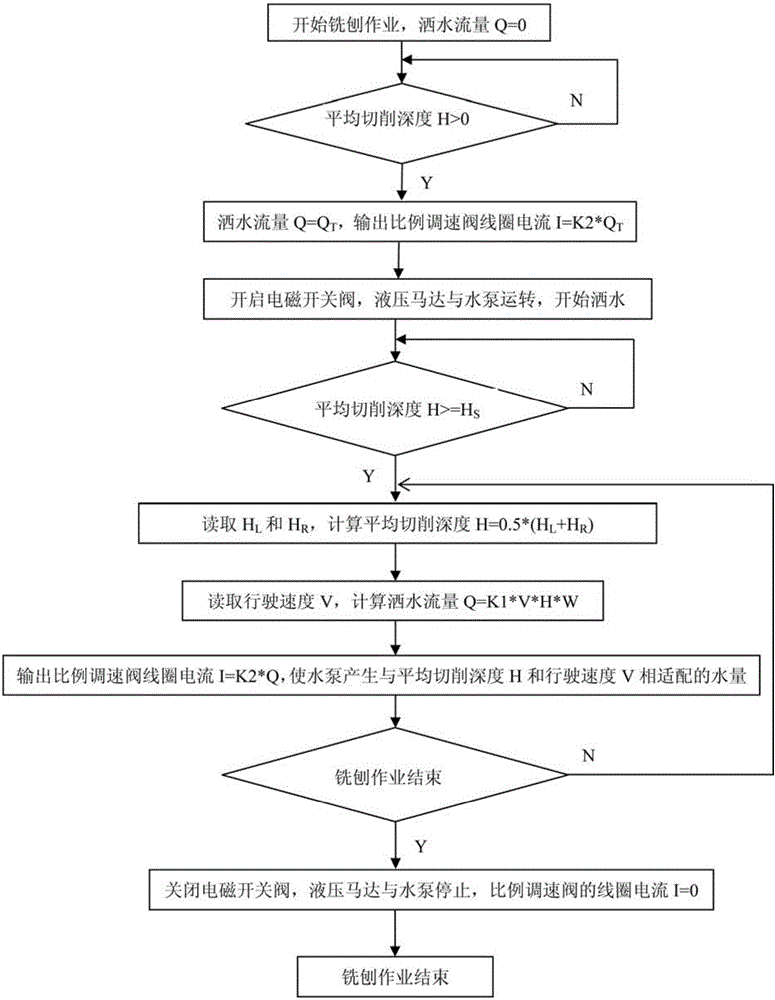

[0030] like figure 1 As shown, the milling machine sprinkling control system of the present invention includes a hydraulic control circuit and a water circuit arranged on the milling machine body (not shown in the figure), wherein the water circuit includes a water pump 9 and a water sprinkling device connected to the water pump 9 A waterway pipeline 8, one end of the waterway pipeline 8 is connected to a water source; the hydraulic control circuit includes a hydraulic oil pipeline 3 whose oil inlet and oil outlet are connected to the hydraulic oil tank 1 located on the milling machine body, and the hydraulic oil pipeline 3 is connected From one end of the oil inlet, a hydraulic pump 2 and a hydraulic motor 6 for driving the water pump 9 to run at the same speed are arranged in sequence. In this embodiment, the two ends of the hydraulic control pipeline 3 need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com