Bush-type pile shoe jetting system for self-elevating drilling platform

A drilling platform, jack-up technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of subsea soil blockage of branch pipelines and main pipes of the pile punching system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

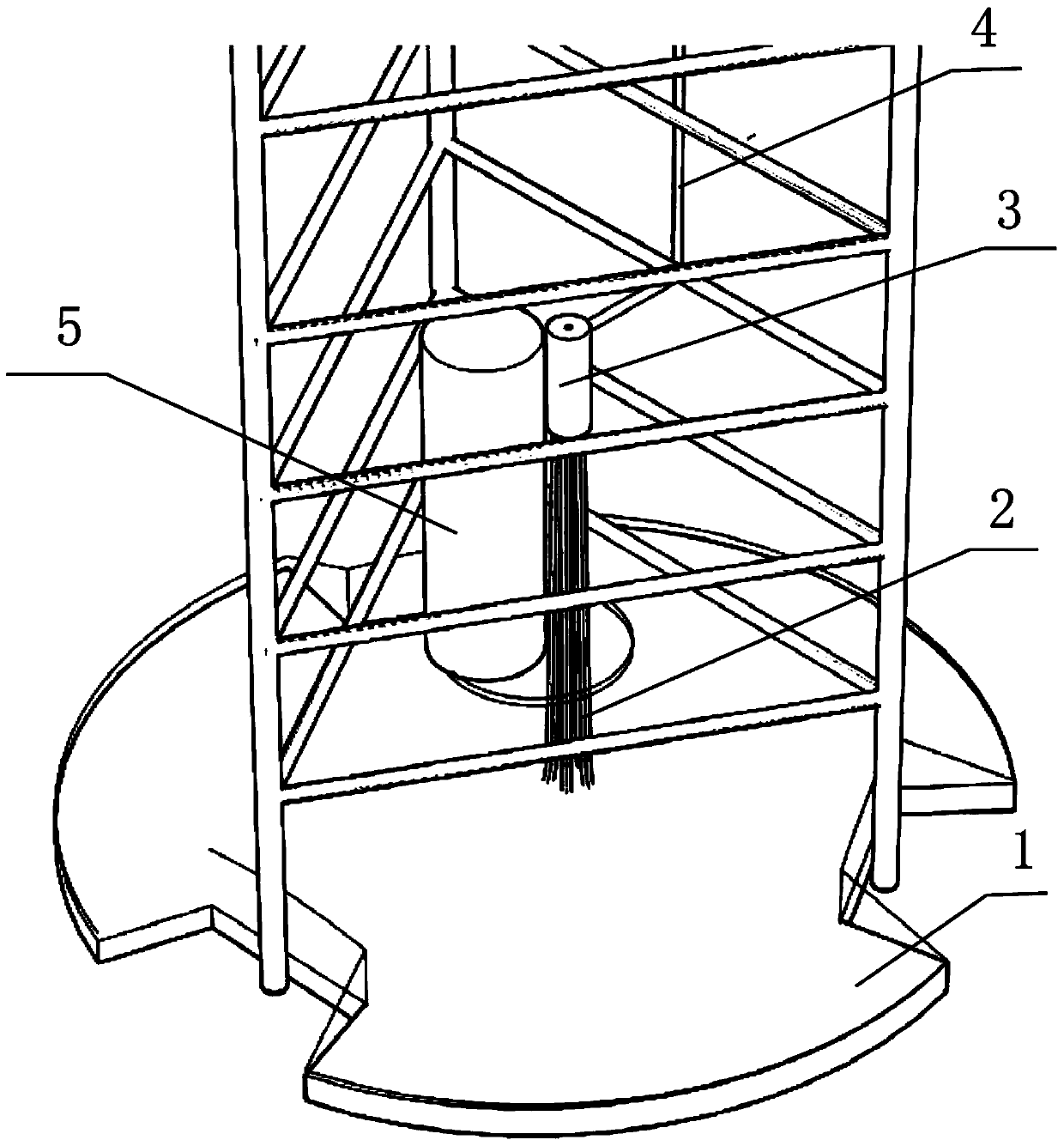

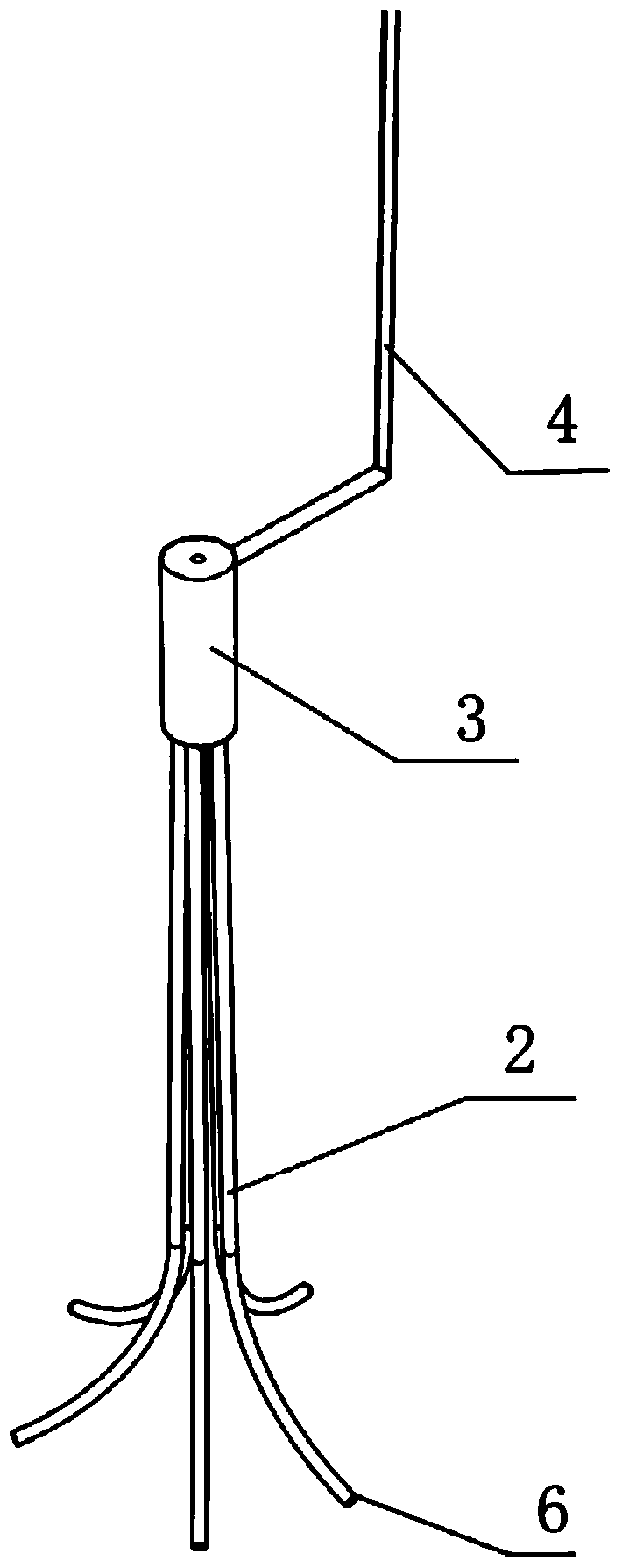

[0021] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the following in conjunction with the attached Figure 1-2 The embodiments of the present invention are described, and it should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0022] like Figure 1-2 As shown, it is a schematic diagram of an embodiment of the bush-type spud-can pile flushing system of the self-elevating drilling platform of the present invention, including the spud can 1, the spud legs arranged on the spud can 1, and the spud shoe manhole 5 arranged on the spud can 1 . The system also includes at least one group of bundled header modules, especially more than two groups ( figure 1 Only one set is shown). Each group of bundled main pipe modules includes a bundled main pipe 3, a plurality of branch pipes 2 in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com