High-compressive hydraulic cylinder

A technology of hydraulic cylinder and cylinder block, applied in the direction of engine, wind power generation, wind engine control, etc., can solve the problems of unsatisfactory sealing effect, low reliability, low stability, inability to withstand high pressure, etc., and achieve guaranteed performance. , good wear resistance, increase the effect of dynamic and static sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

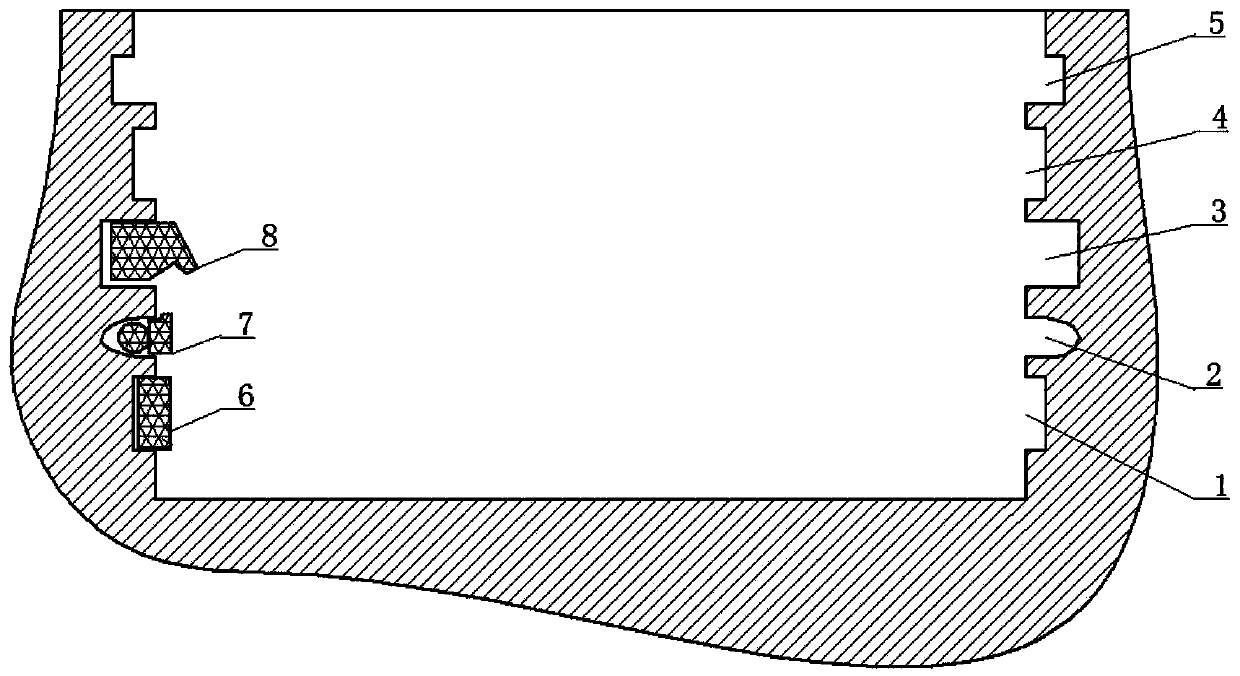

[0014] As shown in Figure 1, a high-pressure hydraulic cylinder includes a U-shaped cylinder body, and the inner wall of the cylinder body has a bottom guide ring groove 1, a sealing ring groove 2 and a dust-proof ring groove 5 from bottom to bottom, and guides at the bottom. The guide ring 6 is embedded in the ring groove 1, the sealing ring groove 2 is U-shaped, the sealing ring 7 is embedded in the sealing ring groove 2, and the sealing ring 7 is a Ster seal sealing ring. There is also a secondary sealing ring groove 3 in between, the secondary sealing ring groove 3 is a square structure, the secondary sealing ring groove 3 is inlaid with a secondary sealing ring 8, and the part embedded in the secondary sealing ring groove 3 is a square structure, protruding Some are inverted V-shaped structures.

[0015] Among them, the Ster seal sealing ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com