Parking braking pawl of automatic gearbox

An automatic transmission and pawl technology, applied in the fields of pawl, automatic transmission parking brake, and automatic transmission parking brake pawl, can solve problems such as pawl breakage, achieve high safety factor, reduce fracture risk, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

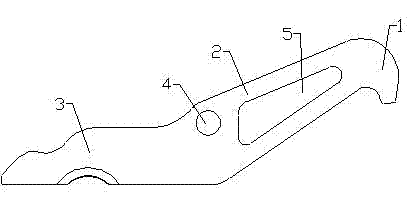

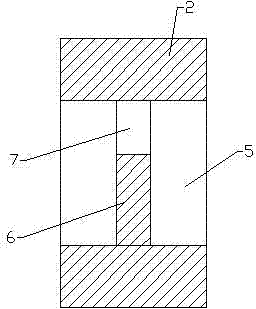

[0023] Example 1, such as image 3 and Figure 4 As shown, a parking brake pawl for an automatic transmission includes a pawl head 1, a pawl body 2 and a pawl tail 3, a pin hole 4 is provided on the pawl, and a pawl body 2 at the front end of the pin hole 4 A cavity 5 is provided. In order to reduce the fracture risk of the ratchet, a reinforcing rib 6 is provided in the middle of the cavity 5. The thickness of the reinforcing rib 6 is 2.54 mm. A torsion spring mounting hole 7 runs through the reinforcing rib 6. The torsion spring installation hole 7 is used for installing a torsion spring, and the center of gravity of the pawl is located at the rear end of the pin hole 4 .

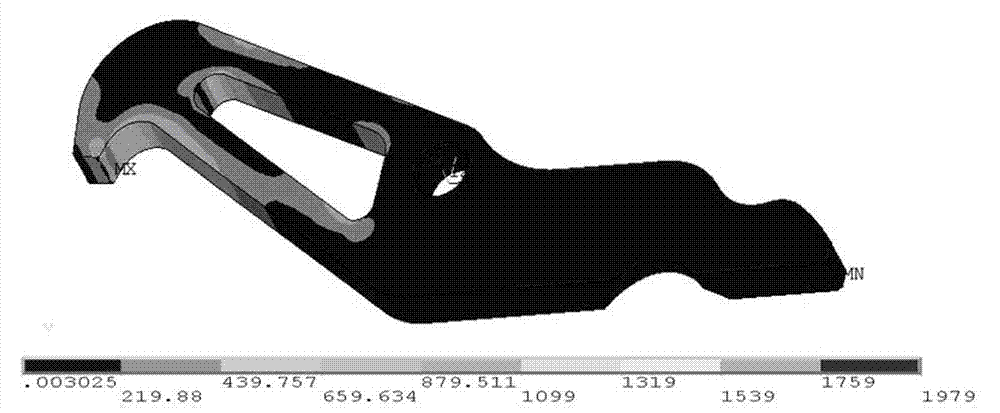

[0024] like Figure 5 As shown, under the same force, the stress of the ratchet head is basically the same as that of the prior art, but in the counterweight region, the stress of the ratchet is lower than 250MPa, and the safety factor High, not easy to break.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com