Inlet tongue plate for rotary kiln

A technology of rotary kiln and tongue, which is applied in the field of rotary kiln inlet tongue, which can solve the problems of weak connection, short service life, affecting production, etc., and achieve the effects of good fixing effect, fast heat dissipation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

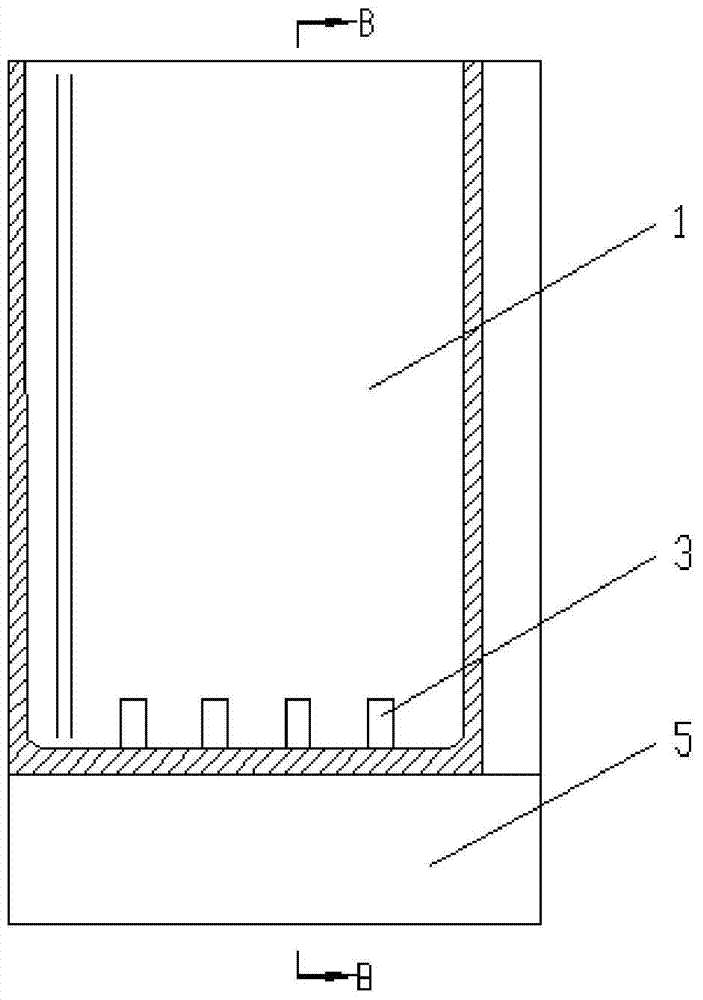

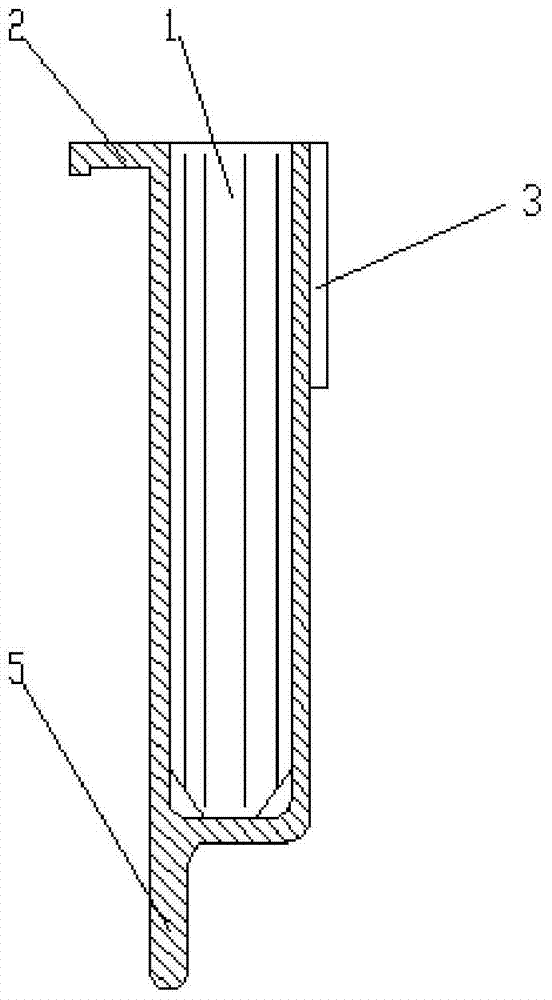

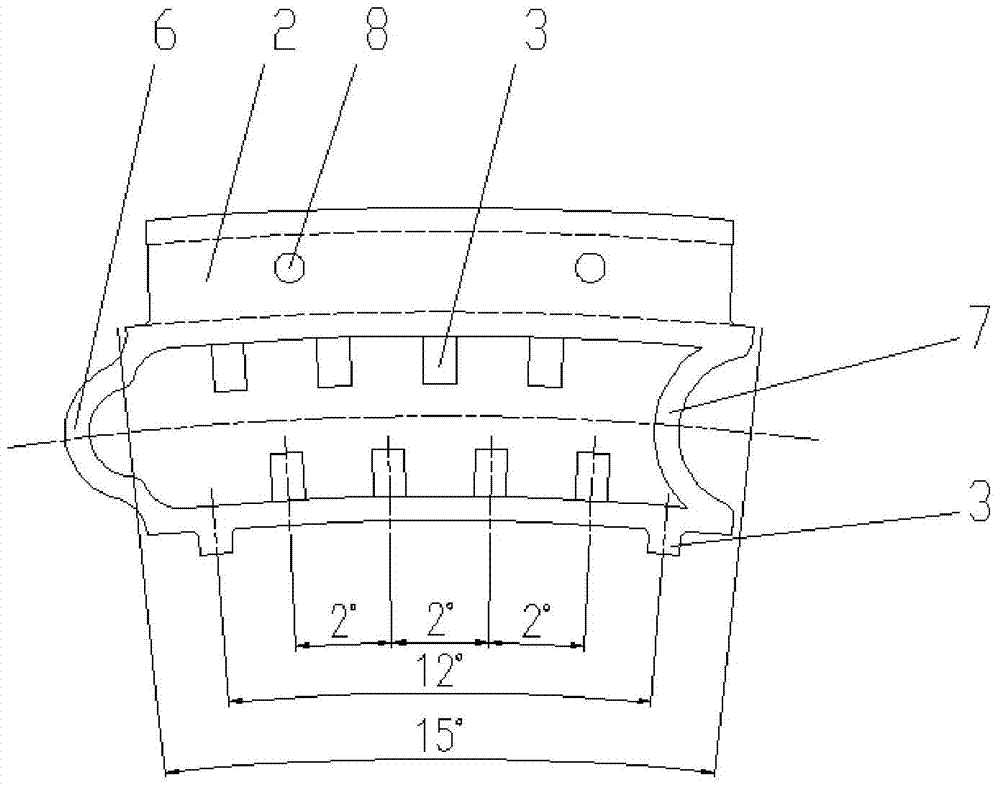

[0018] Such as Figure 1 to Figure 3 As shown, a tongue plate at the entrance of a rotary kiln includes a main body 1, a fixed connection flange 2 arranged on the top of the main body 1, a bolt hole 8 on the fixed connection flange 2, and a guide supporting plate 5 arranged at the bottom end of the main body 1; The interior of the main body 1 is hollow, and the top end of the hollow part is open. The opposite side walls of the main body 1 form a concave surface 7 and a convex surface 6 that can engage with each other.

[0019] In order to better improve the strength of the tongue plate, make the tongue plate evenly stressed and ensure the service life, preferably, the radial angle between the concave surface 7 and the convex surface 6 on the main body 1 is 15 degrees.

[0020] In order to increase the strength of the tongue plate, further, a plurality of ribs 3 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com