Rough and fine combined reflecting mirror attitude quantitative adjusting method and device

A technology of quantitative adjustment and adjustment method, applied in installation, optics, instruments, etc., can solve the problems of limited adjustment efficiency by the technical level and work experience of the adjustment personnel, difficulty in real-time reading display, affecting system performance, etc. Feed resolution capability, high axial feed resolution capability, and the effect of achieving smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

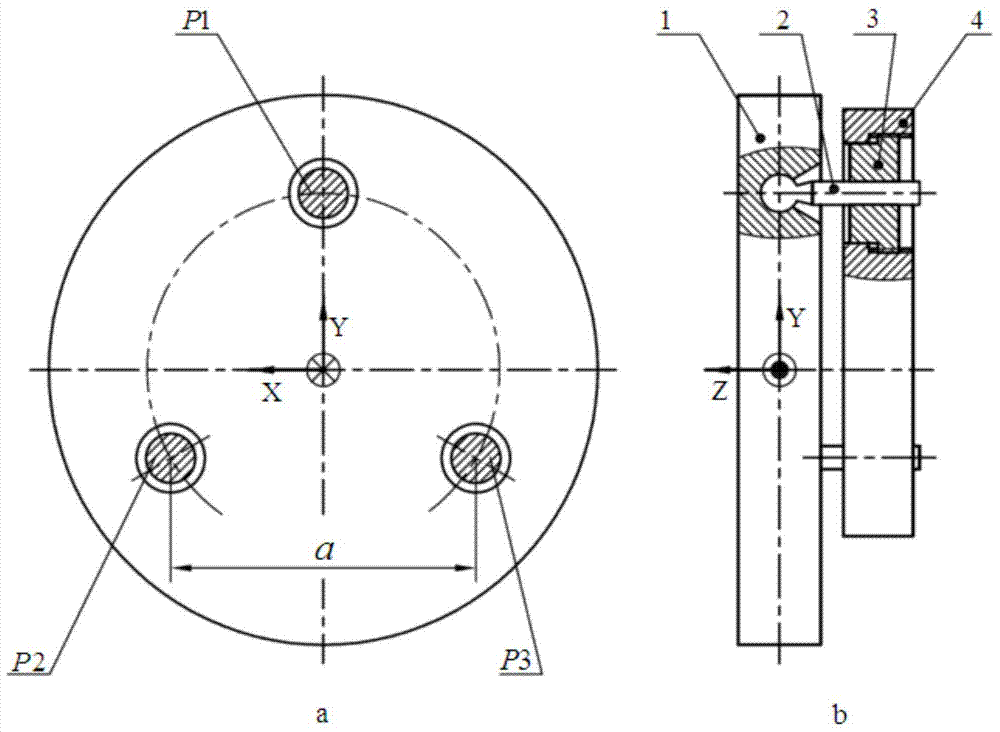

[0029] Such as figure 1 As shown, a in the figure shows that the reflector 1 adopts a three-point support form on the back, and the reflector 1 is supported by three support rods 2 uniformly distributed on the back to the mirror fixing bracket 4 through the adjustment mechanism 3, as shown in b in the figure, the support rod 2 It is connected with the reflector 1 by a ball joint. The translation of the mirror 1 along the normal direction (Z direction) and the degree of freedom adjustment of the tilt of the mirror surface around the X-axis and Y-axis are realized by controlling the different feed amounts of each support rod 2 by the adjustment mechanism 3 .

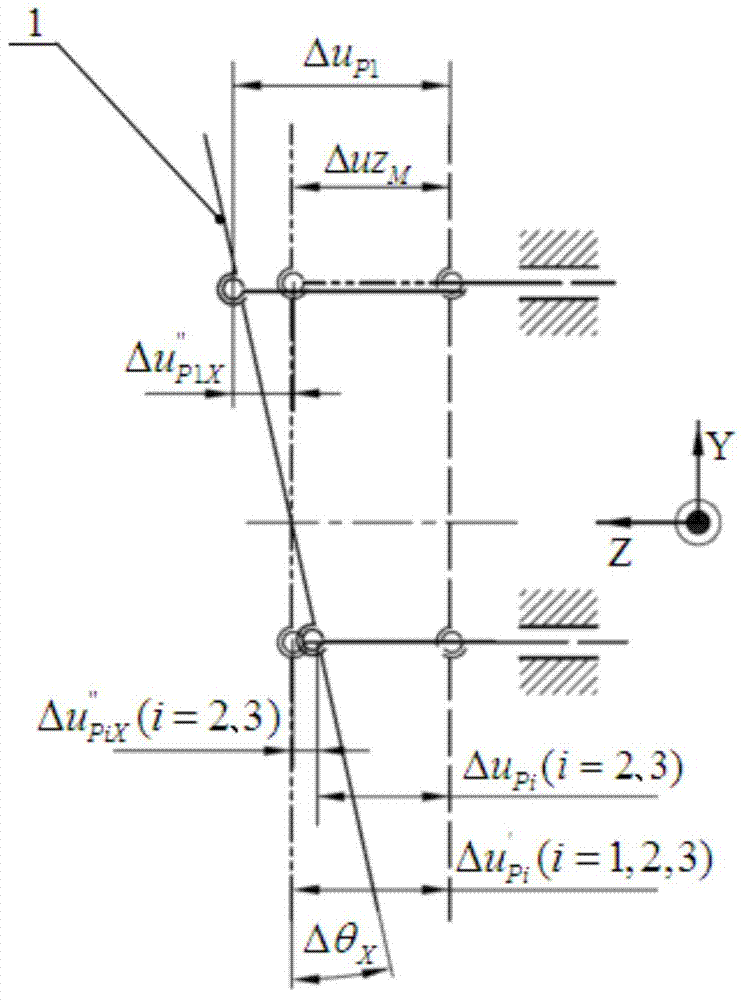

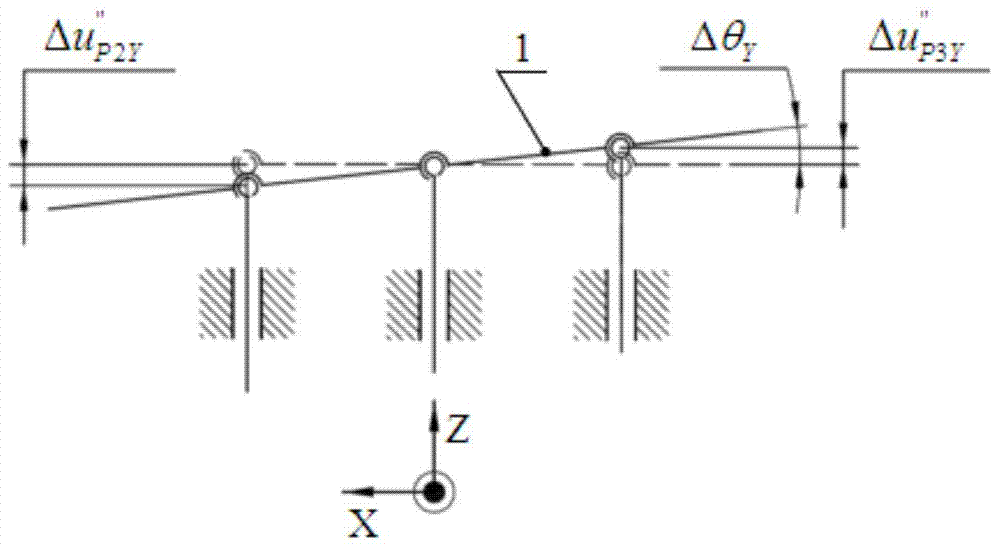

[0030] The calculation process of the translation of the mirror 1 along the normal direction of the mirror surface, the adjustment of the tilt attitude around the X and Y axes of the mirror surface, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com