Automatic CKD (completely knock down)/SKD (semi knock down) inventory generation method

An automatic generation and checklist technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, batch rework, etc., and achieve the effect of avoiding low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

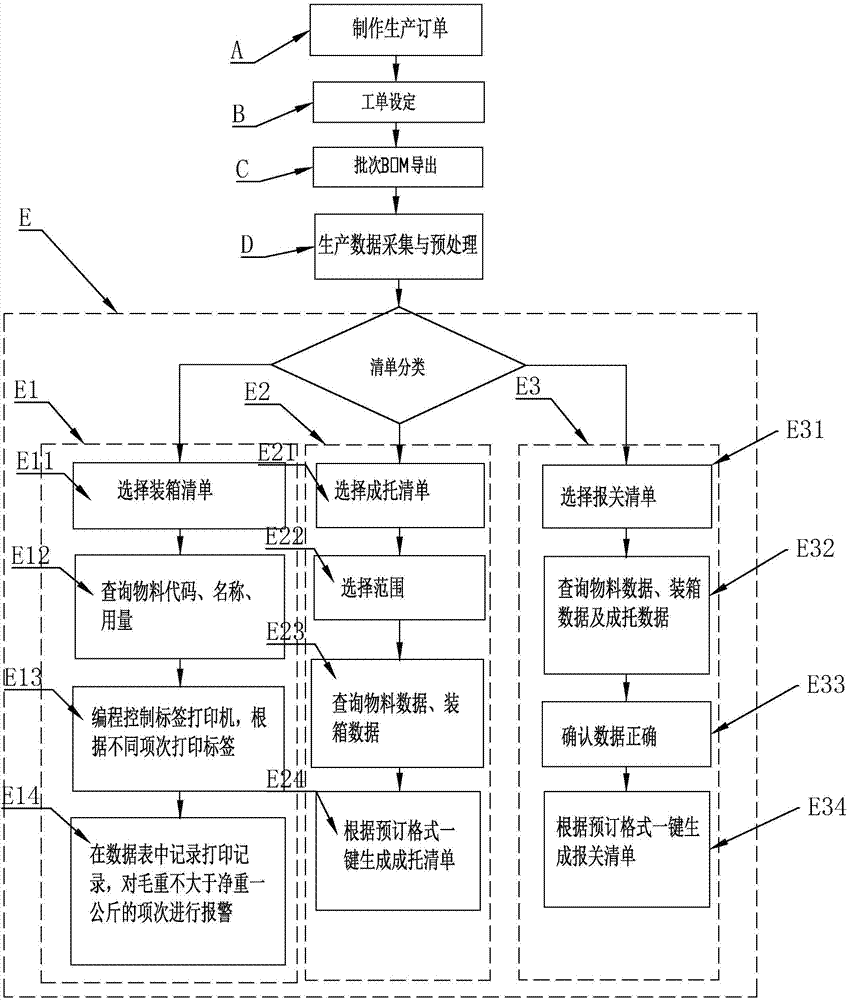

[0035] refer to figure 1 As shown, it is the automatic generation method of CKD / SKD list of the present invention, based on the database of production materials, the database contains the corresponding relationship between various materials and material parameters, wherein the material parameters include the code, batch, weight, Quantity, size, and foreign language translation include the following steps:

[0036] A makes a production order;

[0037] B sets a work order according to the production order, and the work order contains at least one batch of material list;

[0038] C Export all BOMs contained in the work order;

[0039] D Production data collection and preprocessing, that is, sorting, statistics, and translation of material descriptions for the bill of materials;

[0040] E Determine the BOM category and print it.

[0041] Among them, step E includes: E1 packing list printing, E2 palletizing list printing, E3 customs declaration list printing and other three au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com