Outer rotor synchronous magnetic resistance motor rotor

A synchronous reluctance motor and outer rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of unspecified thickness, width, distribution, strength of magnetically conductive and non-magnetically conductive channels. and stiffness, reduce reluctance torque and other problems, to achieve the effect of convenient manufacturing, improve reluctance torque, improve inductance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

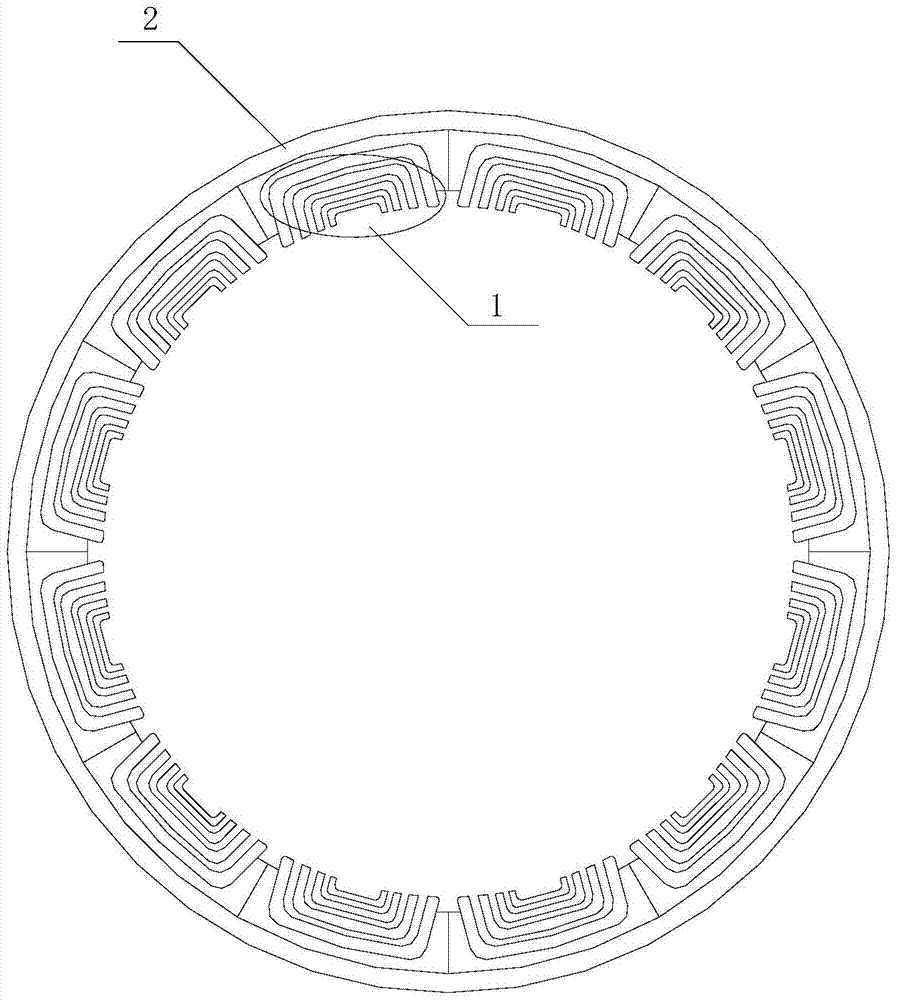

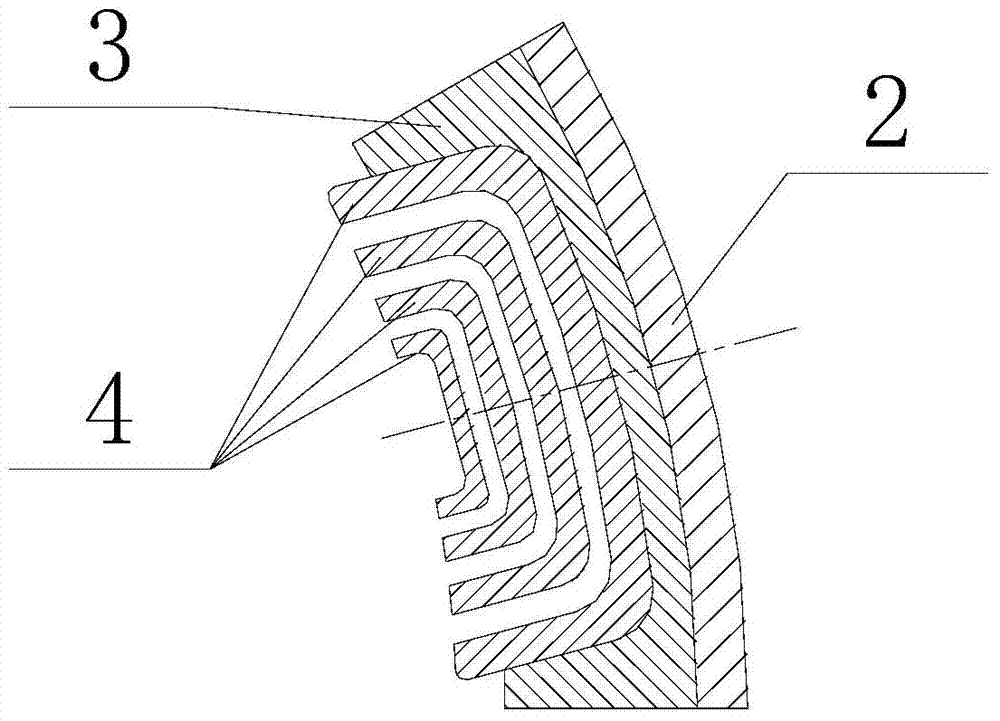

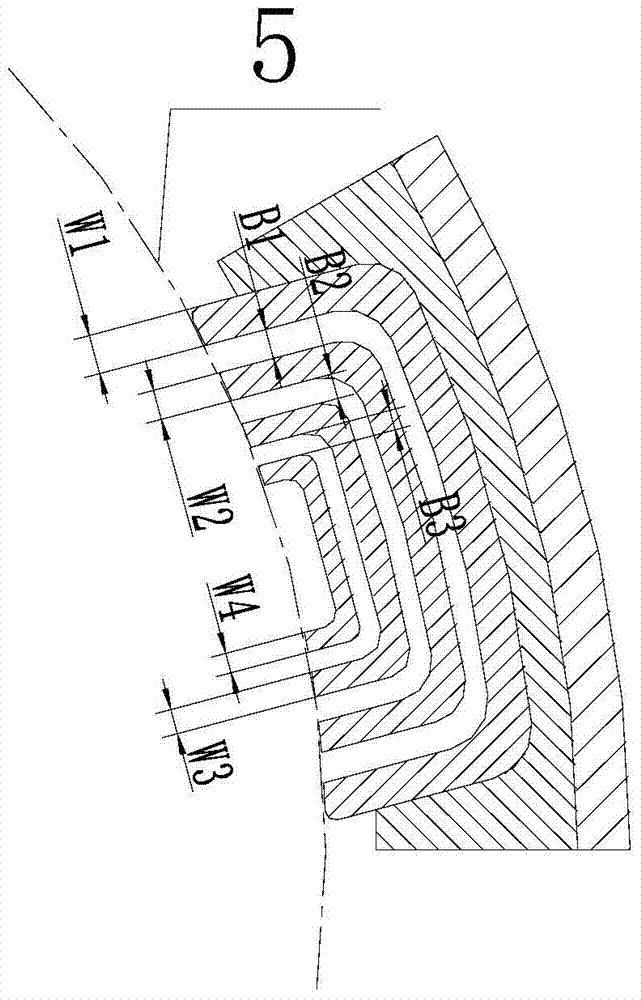

[0028] refer to Figure 1-5 , an outer rotor synchronous reluctance motor rotor, including a rotor yoke 2, the rotor yoke 2 is installed with an even number of pole units 1 uniformly distributed along the circumference, the pole unit 1 includes a mounting frame 3, the mounting frame Several magnetic tracks 4 arranged in sequence along the radial direction are installed inside 3 , and gaps are provided between adjacent magnetic tracks 4 . The mounting frame 3 and the rotor yoke 2 are reliably connected, and the connection method may be interference, bonding, welding, expansion, screw fastening and the like. The present invention has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com