roller brush

A roller and bristle technology, applied in the direction of brushes, brush bodies, bristles, etc., can solve problems such as troublesome operation, environmental pollution, and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

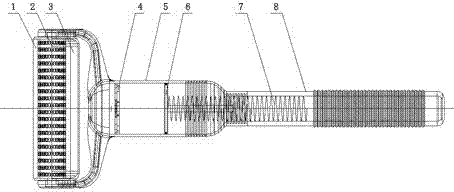

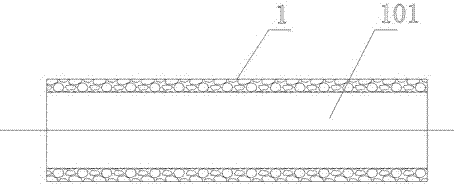

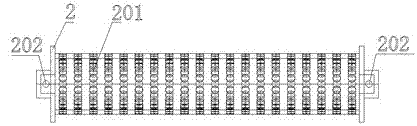

[0036] Referring to the accompanying drawings, the present invention relates to an embodiment of a rolling brush: it is composed of a bristle 1, a cylinder 2, a concave plate 3, a brush body 5, and a brush handle 8. A pair of arms 503 are formed with an insertion opening 501 for inserting the cylinder end of the drum 2 at one end of the arm 503 of the arm 503. In addition, an insertion opening 501 facing opposite is formed at the cylinder end of the other drum 2, facing each other. The inner side of the insertion opening 501 of the cylinder 2 contains surface walls opposite to each other in a manner similar to the insertion edge of the surface side in a connected state. The surface walls are formed to have a through hole 502 connected with the brush body. In a similar manner to the side insertion edge, the opposite surface walls of the insertion port are formed to have a throttling orifice 202 connected to the drum, and a U connecting a pair of arms 503 to each other is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com