Fire-fighting control system for oil depot

A control system and fire-fighting technology, applied in fire rescue and other directions, can solve problems such as difficulty in ensuring fire safety in oil tank farms, complicated processes, loss of life and property of the country and people, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

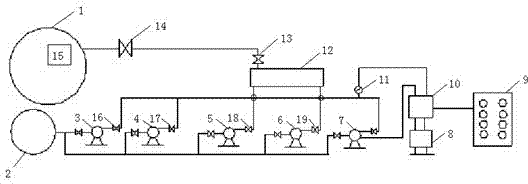

[0016] Such as figure 1 as shown, figure 1 It is a structural diagram of the oil depot fire control system of the present invention. The oil depot fire control system includes diesel engine fire pump 3, electric motor fire pump 4, diesel engine foam pump 5, motor foam pump 6, voltage regulator pump 7, PC 8, one-button control panel 9, PLC10, water pipe network pressure transmitter 11. Foam proportional mixing device 12, foam proportional mixing device outlet valve 13, foam outlet valve 14 of crude oil storage tank, temperature sensor 15, diesel engine fire pump outlet valve 16, motor fire pump outlet valve 17, diesel engine foam pump outlet valve 18 and Motor foam pump outlet valve 19. exist figure 1 Among them, diesel engine fire pump 3, ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com