Diffusion gas flushing system

A technology for diffusing gas and liquid, applied in liquid degassing, chemical instruments and methods, soil material testing, etc., can solve the problems of poor scouring effect, incomplete gas-liquid separation, and large impact, and achieve complete gas-liquid separation and reduce error, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

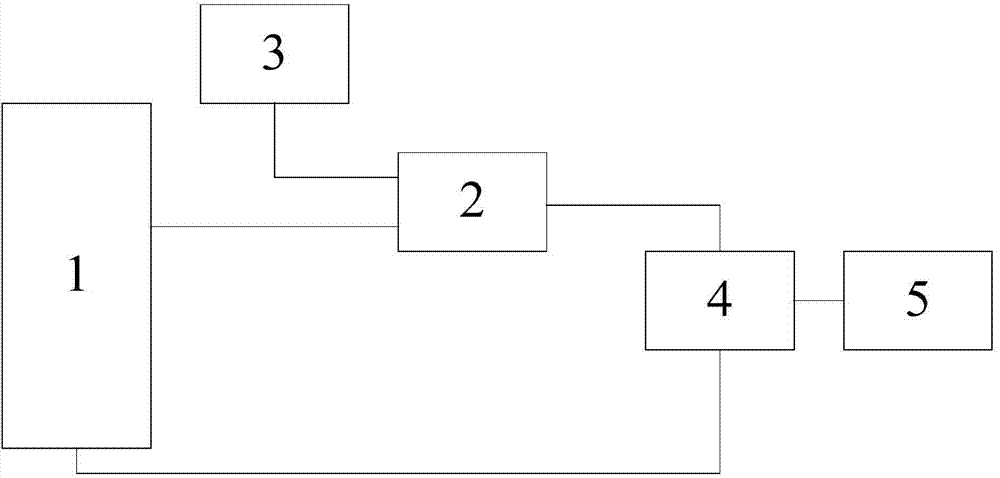

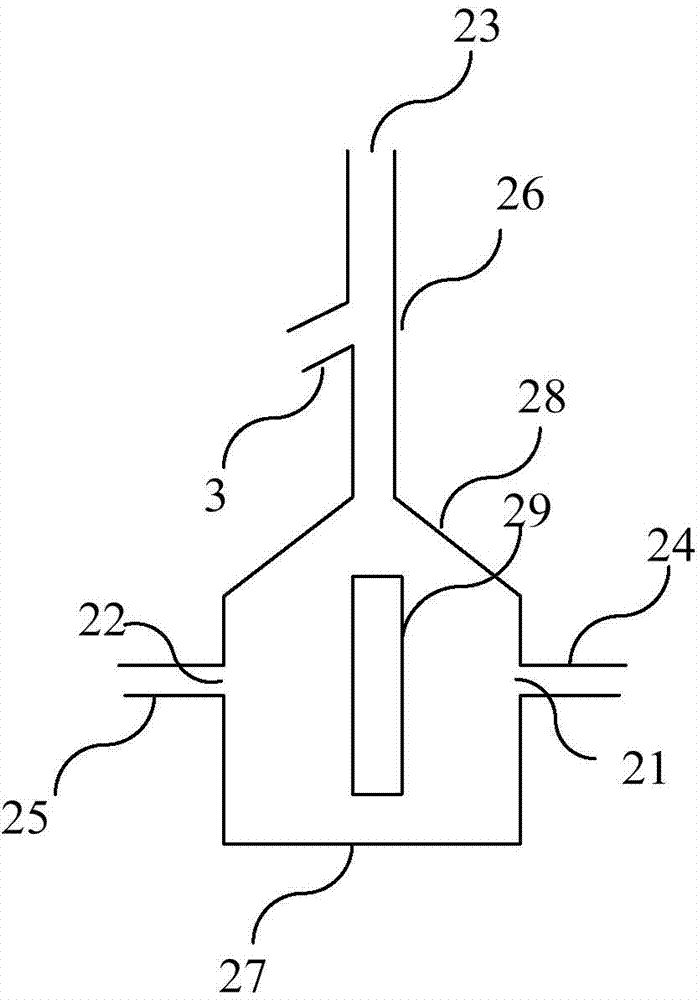

[0027] Such as figure 1 and 2 Shown are a schematic structural diagram of a preferred embodiment of the diffused gas flushing system and a cross-sectional view of the gas-liquid separation device, respectively, according to the present invention.

[0028] The diffused gas flushing system of the present invention is used to connect with the measuring instrument 1 for measuring the volume change of the liquid in the unsaturated soil, and scours the diffused gas in the liquid in the unsaturated soil discharged by the measuring instrument 1 to discharge the liquid.

[0029] The diffusion gas flushing system includes a gas-liquid separation device 2 and a water pump 4 . The gas-liquid separation device 2 includes a cavity and a partition 29 . The upper end of the hollow chamber is provided with an exhaust port 23 for exhausting diffusion gas in the liquid. A first liquid discharge port 21 and a second liquid discharge port 22 are opened on the side wall of the cavity for liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com