Method for forming stone-like texture coating film and coated article coated with stone-like texture

A texture and coating technology, which is applied to the formation of stone textured coating films and coated articles coated with stone textures, can solve the problem that the coating film formation method is not recorded, and achieve a wide variety of, Presence prominent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, "part" and "%" in the following example represent "part by mass" and "% by mass", respectively.

[0124] [coated board]

[0125] On the slate board (600×900×3mm), the coating amount is 100g / m 2 "EP シーラーtransparency" (manufactured by Kansai Paint Co., Ltd., water-based acrylic emulsion-based sealer) was roller-coated and dried to obtain a coated panel.

[0126] [Primer coating]

[0127] Primer paint (X-1): "Ales Aqua Gloss White" (manufactured by Kansai Paint Co., Ltd., acrylic resin-based water-based paint).

[0128] [Add paint with colored paint particles]

[0129]

manufacture example 1

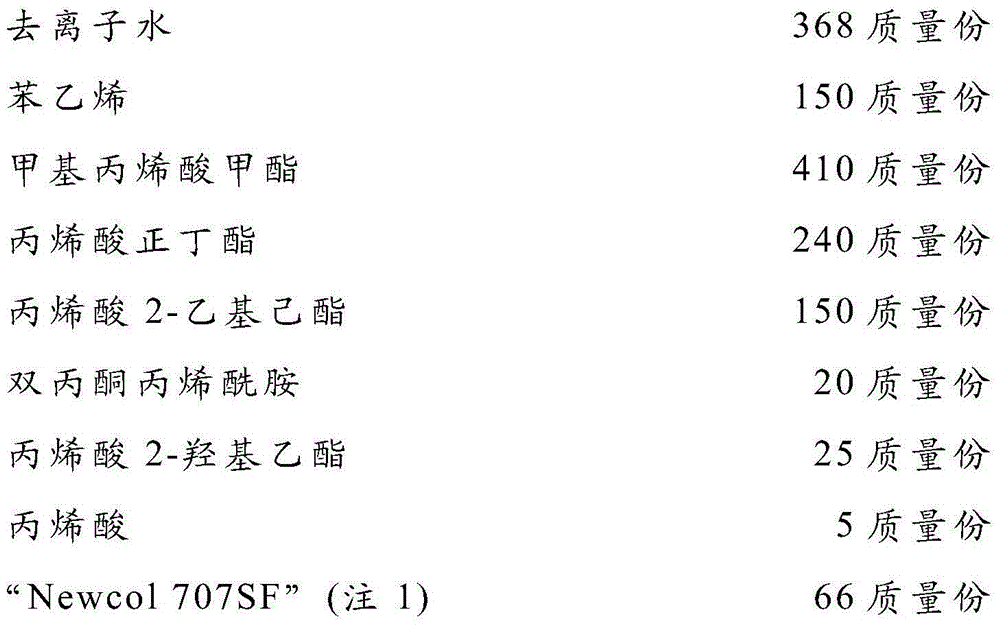

[0131] 285 parts by mass of deionized water and 1 part by mass of "Newcol 707SF" (Note 1) were added to a four-necked flask with a capacity of 2 liters, and nitrogen substitution was performed, followed by maintaining at 85°C. 3% parts of the pre-emulsion (preemulsion) formed by emulsifying the components of the following composition were added thereto; 123 parts by mass of the initiator aqueous solution obtained by dissolving 3 parts by mass of ammonium persulfate in 120 parts by mass of deionized water Of these, 41 parts by mass were added dropwise to the flask over 4 hours after 20 minutes after the addition was completed.

[0132]

[0133] After completion of the dropwise addition, it was further kept at 85° C. for 2 hours, then the temperature was lowered, and the pH was adjusted with aqueous ammonia when it reached 40 to 60° C. to obtain an emulsion (a1) with a solid content of 55%. The average particle diameter of the emulsion (a1) was 175 nm, and pH was 8.3.

[013...

manufacture example 2

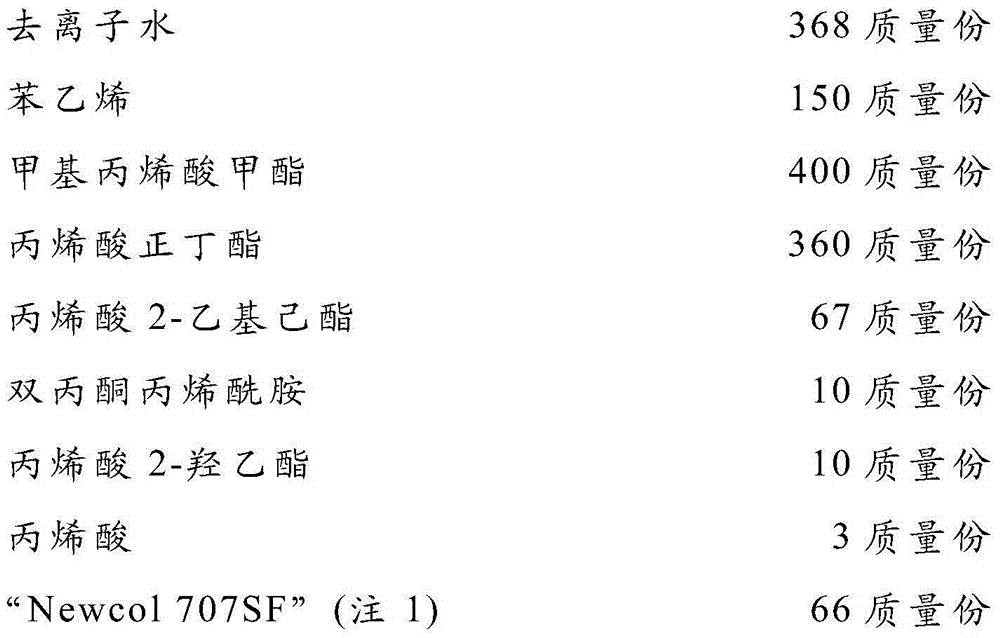

[0137] 285 parts by mass of deionized water and 1 part by mass of "Newcol 707SF" (Note 1) were added to a four-necked flask with a capacity of 2 liters, and nitrogen substitution was performed, followed by maintaining at 85°C. 3% of the pre-emulsion obtained by emulsifying the components of the following composition, and 123 parts by mass of an initiator aqueous solution obtained by dissolving 3 parts by mass of ammonium persulfate in 120 parts by mass of deionized water were added thereto. 41 parts by mass, and 20 minutes after the addition was completed, the remaining pre-emulsion and ammonium persulfate aqueous solution were dripped into the flask over 4 hours.

[0138]

[0139] After the dropwise addition was completed, it was further kept at 85°C for 2 hours, and then the temperature was lowered to 40˜60°C. Next, the pH was adjusted with aqueous ammonia to obtain an emulsion (a2) with a solid content of 55%. The average particle diameter of the emulsion (a2) was 180 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com