Stamping mold of special-shaped connecting pipe

A stamping forming and die technology, which is applied in the processing field of special-shaped nozzles, can solve the problems of long manufacturing cycle, high equipment requirements and high forging cost, and achieves the effects of strong die versatility, convenient operation and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

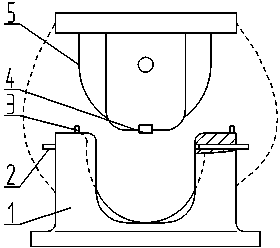

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

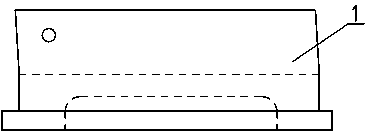

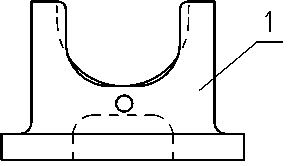

[0022] Such as figure 1 As shown, the molding die structure of the special-shaped connecting pipe includes: connecting die 1, stripping plate 2, positioning plate 3, limit block 4, connecting punch 5; described connecting die 1, one end cross section of connecting punch 5 is Semi-circular, the cross section of the other end is square or semi-elliptical, and the two ends are connected in a conical shape; the positioning plate 3 is in the middle of the connecting die 1, and the limiting block 4 is in the square or semi-elliptical connecting die. Type one end. Take over die 1 and take over punch 5 are made of materials with better self-lubricating properties.

[0023] When in use, install the takeover punch 5 on the central slider of the press; the special-shaped takeover is divided into two symmetrical parts for blanking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com