Automatic assembling machine of electromagnetic coil assembly of regulator

An automatic assembly machine, electromagnetic coil technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of small use range and low assembly efficiency, and achieve the effect of improving production efficiency and simplifying manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

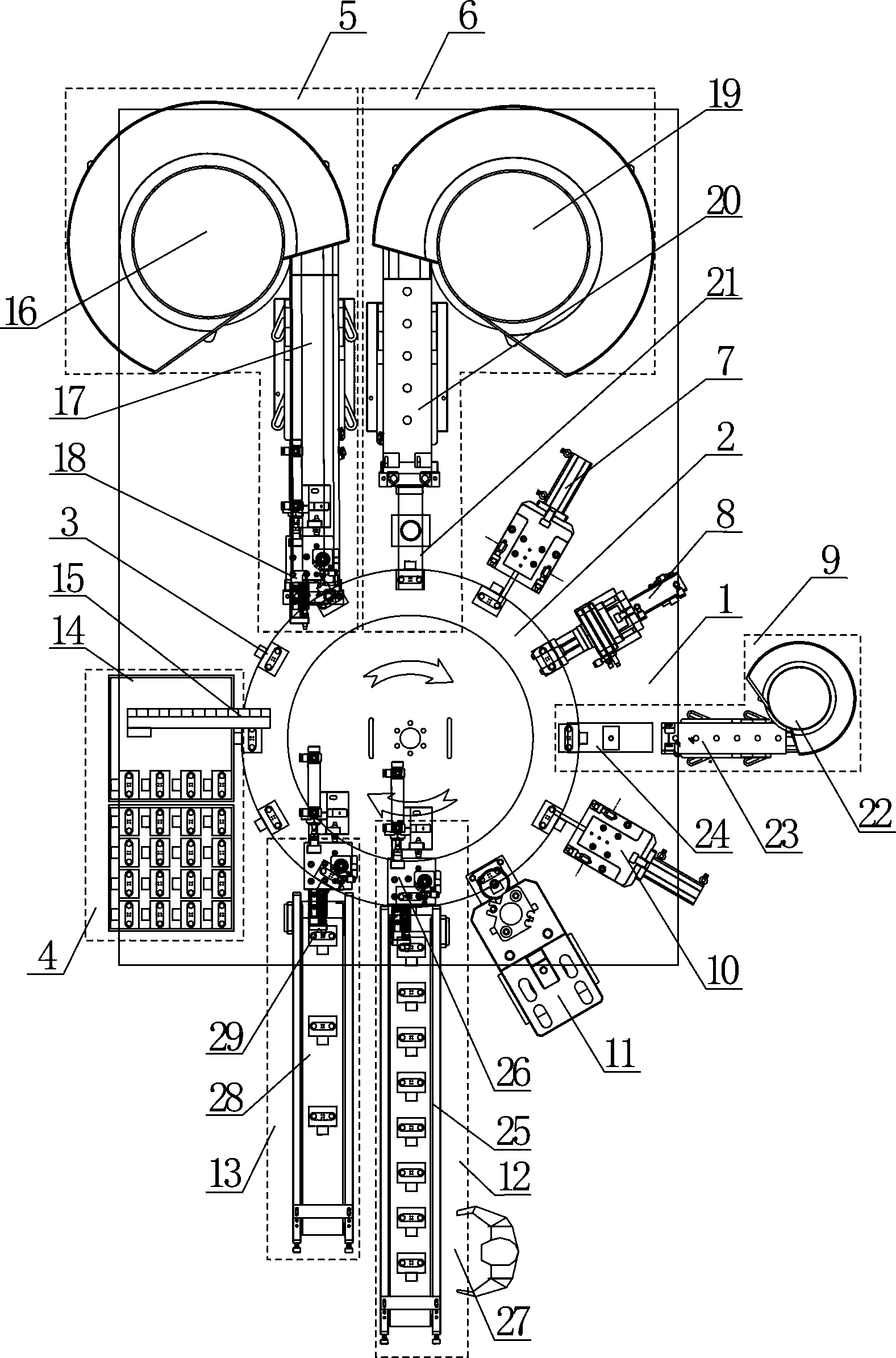

[0017] Such as figure 1 As shown, the automatic assembly machine of the electromagnetic coil assembly of the regulator includes a workbench 1 and an intermittent turntable 2 arranged on the workbench 1. The overall dimensions of the workbench are: the length is 1800mm, the width is 1500mm, The height is 2000mm; the intermittent turntable 2 is evenly spaced with twelve jigs 3 along its periphery, and electromagnetic coil assemblies corresponding to the jigs 3 are sequentially arranged on the workbench 1 and around the intermittent turntable 2 Feeding device 4, solenoid valve assembly feeding device 5, large O-ring loading device 6, large O-ring in-position detection device 7, electromagnetic coil assembly turning manipulator 8, small O-ring loading device 9. Small O-ring in-position detection device 10, grease coating machine 11, qualified electromagnetic coil assembly removal device 12 and unqualified electromagnetic coil assembly removal device 13;

[0018] The electromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com