Tricycle curved beam frame

A tricycle and curved beam technology, which is applied in the field of tricycle curved beam frame, can solve the problems of inability to guarantee the strength of the frame, unfavorable heat dissipation of the engine, large driving vibration, etc., achieve good ventilation effect, obvious synergistic force bearing effect, and improve bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

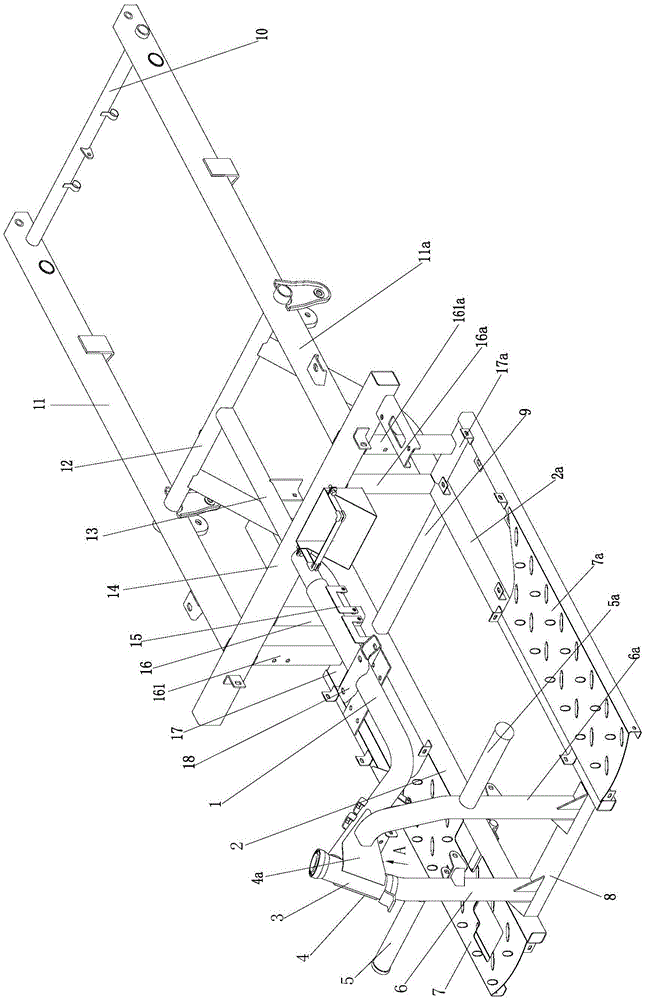

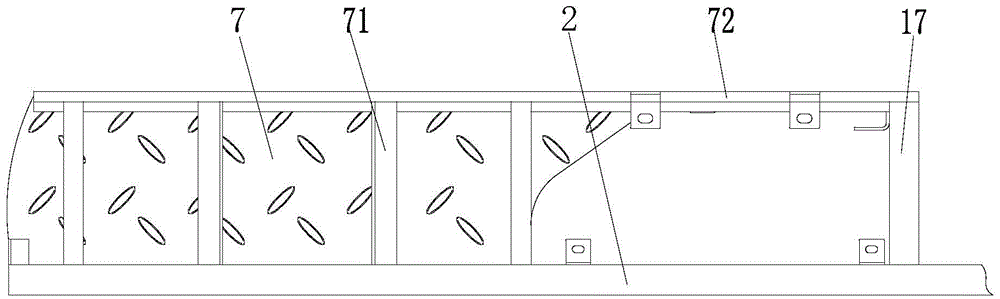

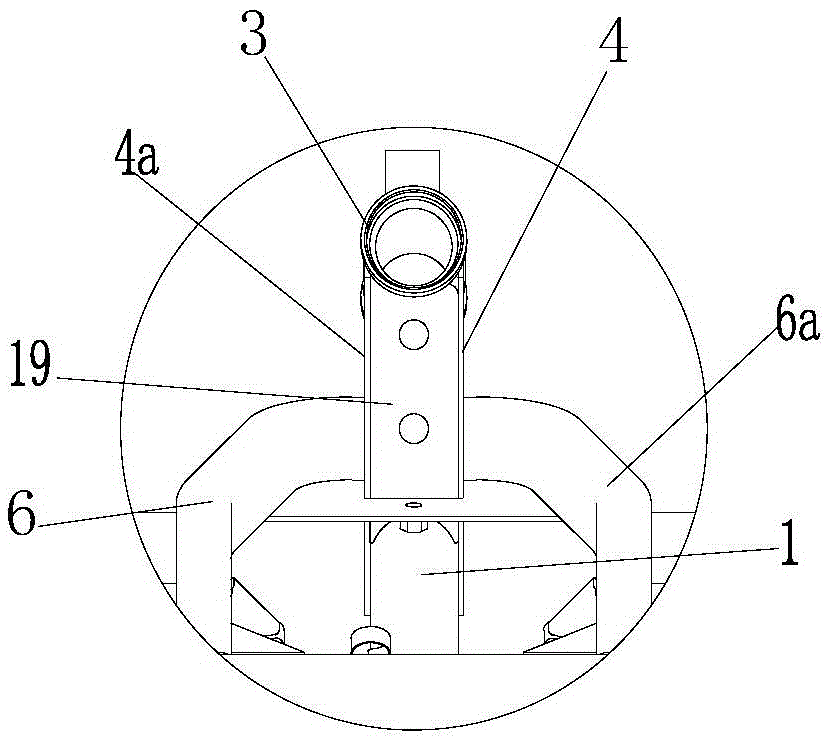

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the pedal assembly, image 3 for figure 1 Partial view along A, as shown in the figure: the tricycle curved beam frame of the present embodiment includes a head pipe 3, a front frame, a main beam 14 and a rear frame that are fixedly connected to each other to form a frame, and the front frame It is integrated with the rear frame through the main beam 14. The front frame includes the left front side beam 2a, the right front side beam 2 and the main beam 1 whose front end is fixedly connected to the head pipe 3 and the rear end is fixedly connected to the main beam 14. The main beam 1 is a curved beam structure with a downward bend; the use of the curved beam structure is beneficial to the arrangement of other equipment. In the present invention, the fixed connection and fixed arrangement generally adopt welding. Of course, the method of assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com