Planar flexible beam unit

A flexible beam and plane technology, which is applied in the direction of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of complex manufacturing of torsion and bending beams, and achieve the effect of lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

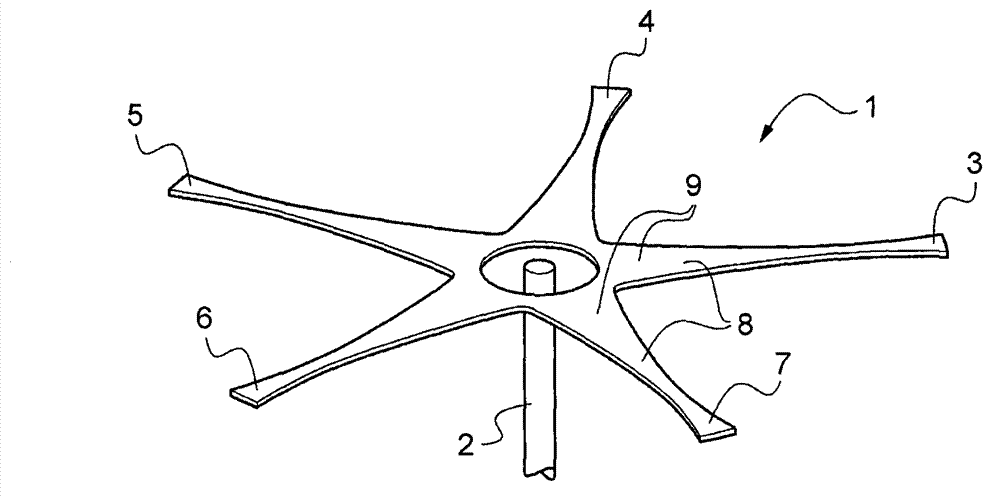

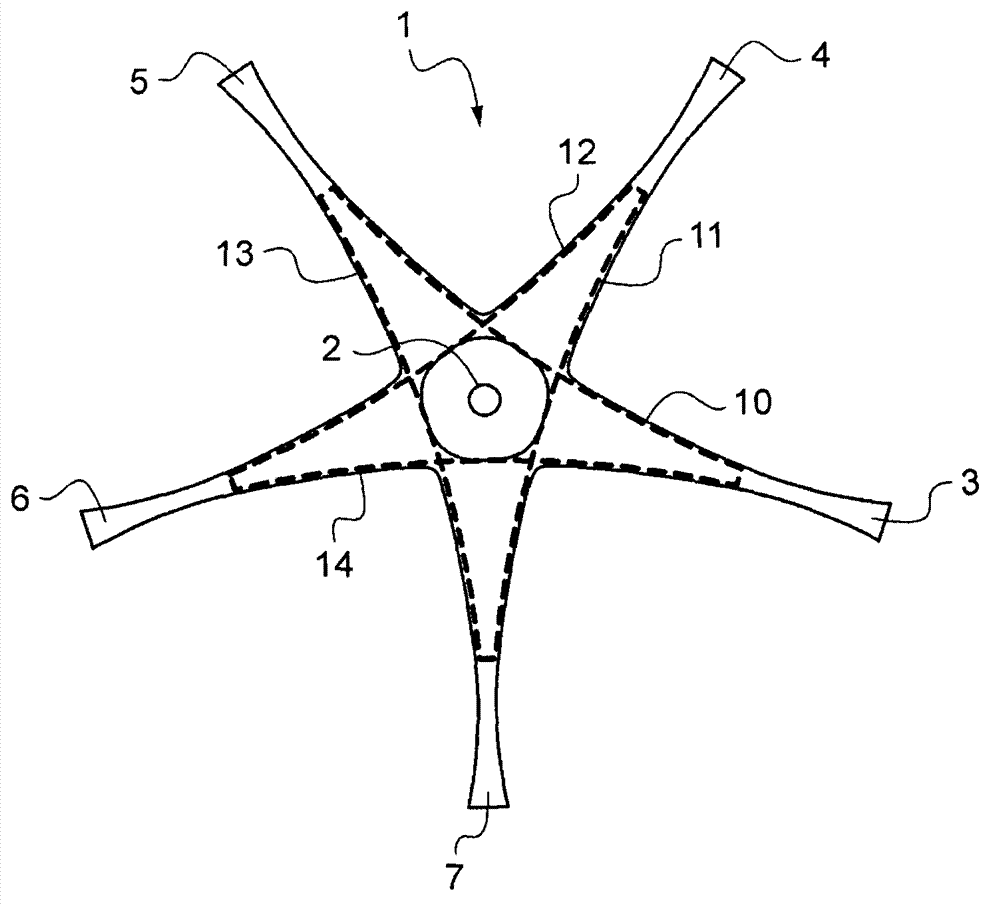

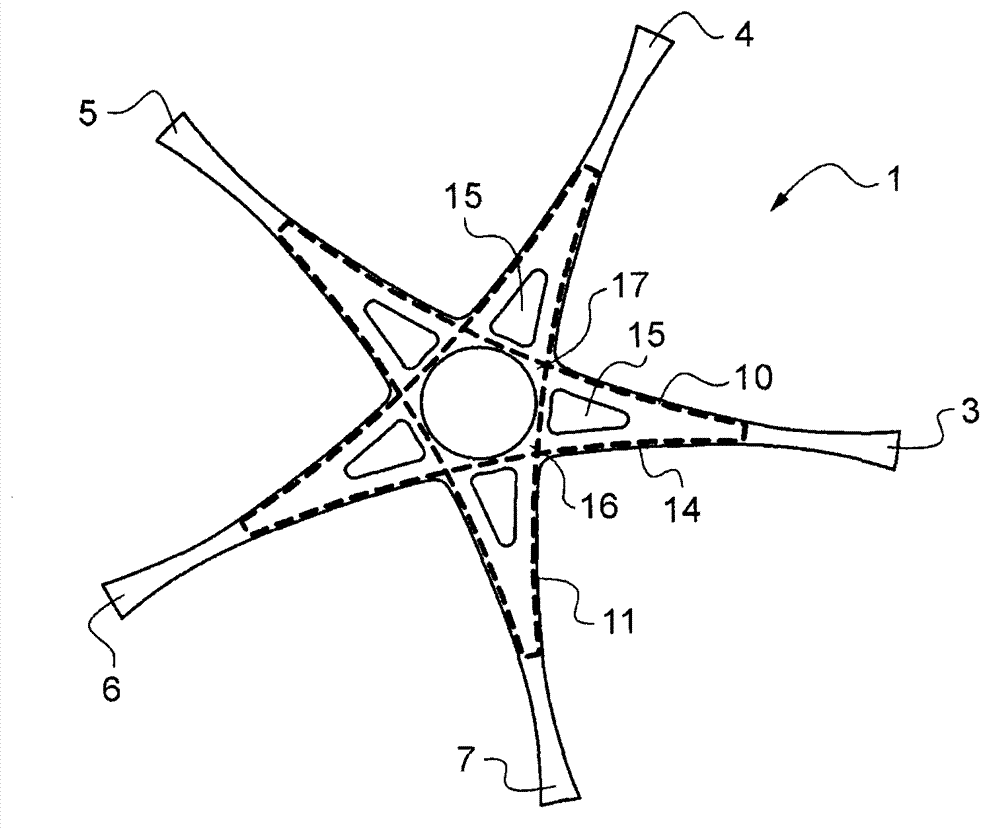

[0032] according to figure 1 , the planar flexible beam unit 1 is centered on the rotor shaft 2 of the multi-bladed main rotor (not shown) of the helicopter. The planar flexbeam unit 1 comprises a concentric hub (not shown) and generally planar five torque arms 3-7 projecting radially from the center and having a generally circular opening. The five torque arms 3-7 are equiangularly spaced. The planar flexible beam unit 1 is made of composite compound.

[0033] Each torque arm 3-7 has a generally inner arc surface 8 on each side of its radial extension, at the root region 9 of said torque arm 3-7 is integral with its adjacent torque arm 3-7, and has Relatively large width, so that the thickness / width ratio is less than 1:3. The thickness is defined perpendicular to the planar flexible beam unit 1 and the width corresponds to the respective extensions of the torque arms 3-7 in their chord direction.

[0034] Such as figure 2 As shown, the corresponding features are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com