Pre-treatment method for deep sludge dewatering

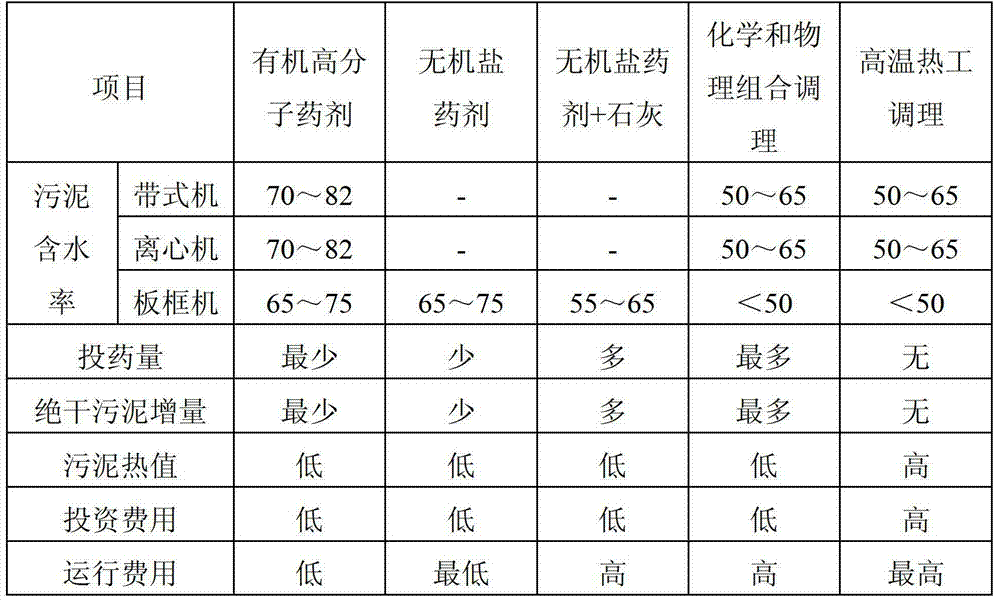

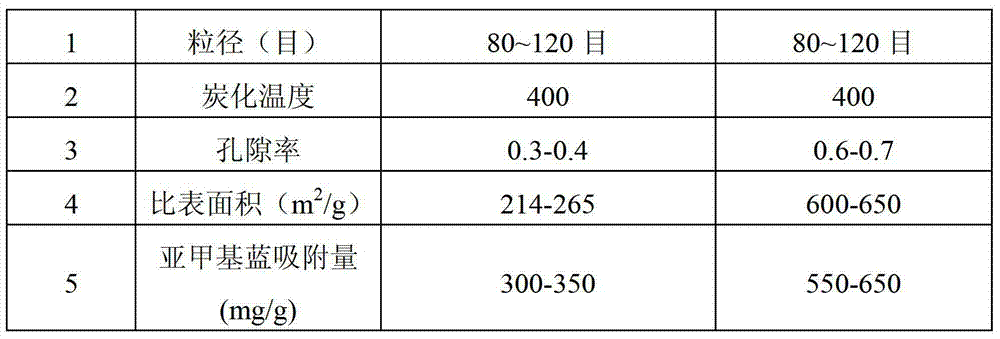

A deep dehydration and pretreatment technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of increasing washing waste liquid, high temperature of pyrolysis, high operating cost, etc., to achieve improved treatment efficiency, good safety and Adsorption performance, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] When the sludge is treated by the present invention, 6 kg of sodium hypochlorite and 30 L of concentrated sulfuric acid are first added to 2000 L of domestic sludge with a water content of 96%, and FeSO is added after stirring for 60 minutes. 4 20kg, ZnCl 2 30kg and stir for 3min, finally add 8kg of octadecyltrimethylammonium chloride and stir for 3min, then use a diaphragm plate and frame filter press to feed the mud for 120min under a pressure of 0.8MPa, and then use a hydraulic pressure to press the diaphragm for 20min under a pressure of 0.8MPa , The mud cake was weighed and the moisture content of the sludge was determined to be 59%.

Embodiment 2

[0055] When the sludge is treated by the present invention, 10 kg of sodium hypochlorite and 40 L of concentrated sulfuric acid are first added to 2000 L of domestic sludge with a moisture content of 96%, and FeSO is added after stirring for 80 minutes. 4 20kg, ZnCl 2 Stir 30kg for 4min, finally add 8kg of octadecyltrimethylammonium chloride and stir for 4min, use a diaphragm plate and frame filter press to feed the mud for 120min under a pressure of 0.8MPa, and then press the diaphragm for 20min under a pressure of 0.8MPa by hydraulic pressure , The mud cake was weighed and the moisture content of the sludge was determined to be 56%.

Embodiment 3

[0057] When the sludge is treated by the present invention, 6 kg of sodium hypochlorite and 30 L of concentrated sulfuric acid are first added to 2000 L of domestic sludge with a water content of 96%, and FeSO is added after stirring for 60 minutes. 4 30kg, ZnCl 2 40kg and stir for 4min, finally add 8kg of octadecyltrimethylammonium chloride and stir for 4min, use a diaphragm plate and frame filter press to feed the mud for 120min under a pressure of 0.8MPa, and then use a hydraulic pressure to press the diaphragm for 20min under a pressure of 0.8MPa , The mud cake was weighed and the moisture content of the sludge was determined to be 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com