A grain mixing and steaming machine

A technology of a steamer and a stirring rod, which is applied in the field of winemaking, can solve the problems of unsanitary, low efficiency, and influence on the quality of steamed wine, and achieve the effect of high work efficiency and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

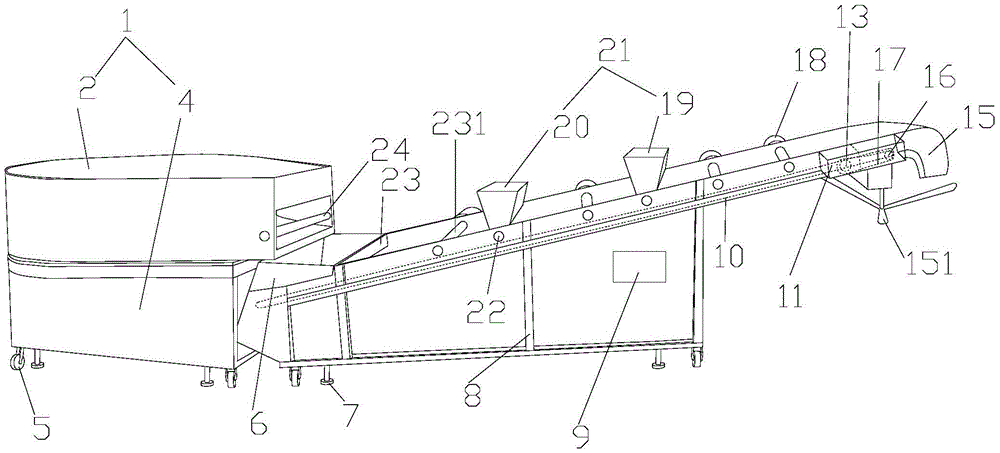

[0028] Such as figure 1 , 3 , a grain mixing and steaming machine, which includes: a main body frame 8, a conveyor belt 10, a transmission motor 11, a dumping device 1, and a spreading funnel 21 for holding wine-making materials and capable of spreading the wine-making materials onto the conveyor belt 10;

[0029] The main frame 8 is provided with a slope, and the conveyor belt 10 is laid along the slope and can move from the bottom of the slope to the top of the slope. The internal connection makes the conveyor belt 10 form a loop, the upper and lower belts of the conveyor belt 10 are parallel to each other, and the movement of the conveyor belt 10 is powered by the conveyor motor 11 installed on the main frame 8;

[0030] The waste dumping device 1 is installed at the bottom of the slope of the main frame 8, and includes a waste dump seat 4, a waste dump box 2 for placing distiller's grains. The opening is located above the slope bottom of the main frame 8. There is a push...

Embodiment 2

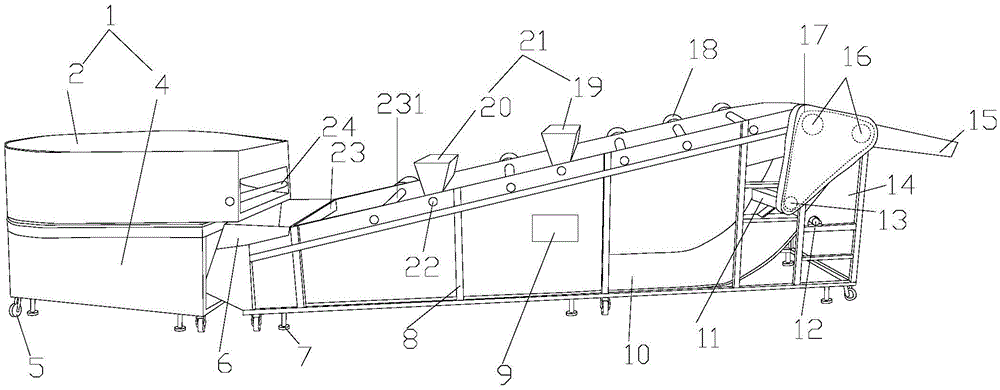

[0043] Such as figure 2 , 3 , a grain mixing and steaming machine, which includes: a main body frame 8, a conveyor belt 10, a transmission motor 11, a dumping device 1, and a spreading funnel 21 for holding wine-making materials and capable of spreading the wine-making materials onto the conveyor belt 10;

[0044] The main frame 8 is provided with a slope, and the conveyor belt 10 is laid along the slope and can move from the bottom of the slope to the top of the slope. The internal connection makes the conveyor belt 10 form a loop, and the movement of the conveyor belt 10 is powered by a conveyor motor 11 mounted on the main body frame 8;

[0045] The waste dumping device 1 is installed at the bottom of the slope of the main frame 8, and includes a waste dump seat 4, a waste dump box 2 for placing distiller's grains. The opening is located above the slope bottom of the main frame 8. There is a pushing device between the dumping box 2 and the dumping seat 4. The pushing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com