Tubular flow pump with partially adjustable guide vane body

A technology of guide vanes and tubular pumps, applied to pumps, components of pumping devices for elastic fluids, pump elements, etc., can solve the problems of water pump efficiency decline, angle difference, impact, etc., and achieve accurate adjustment angles, Adjustment speed is fast and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

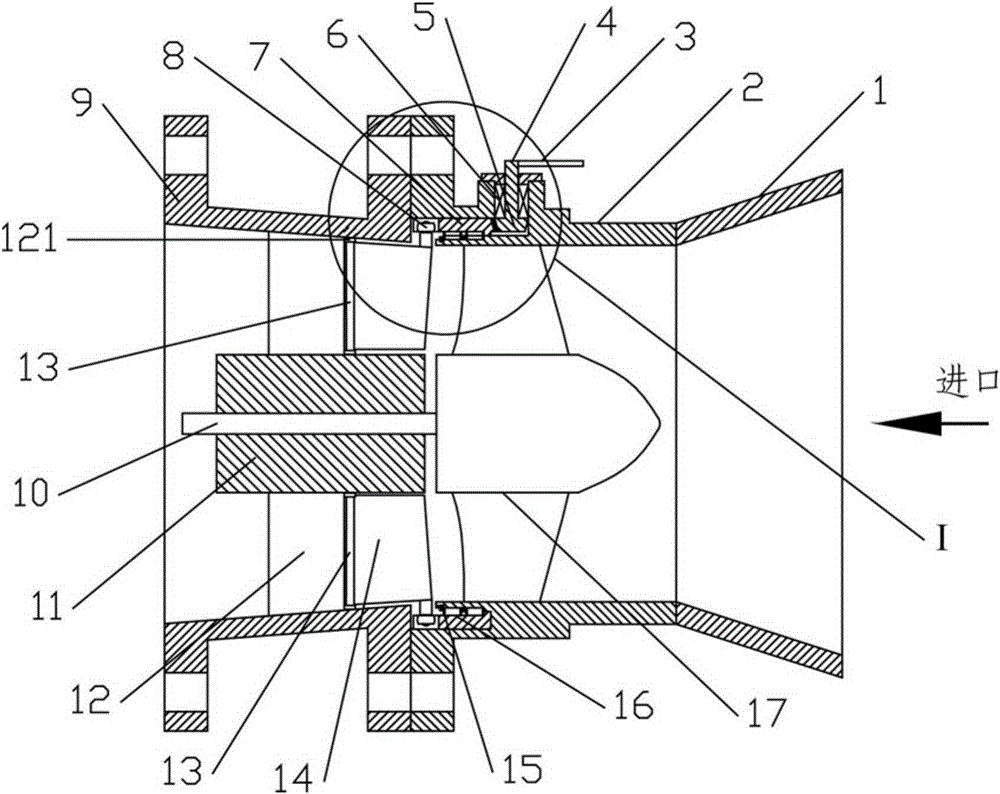

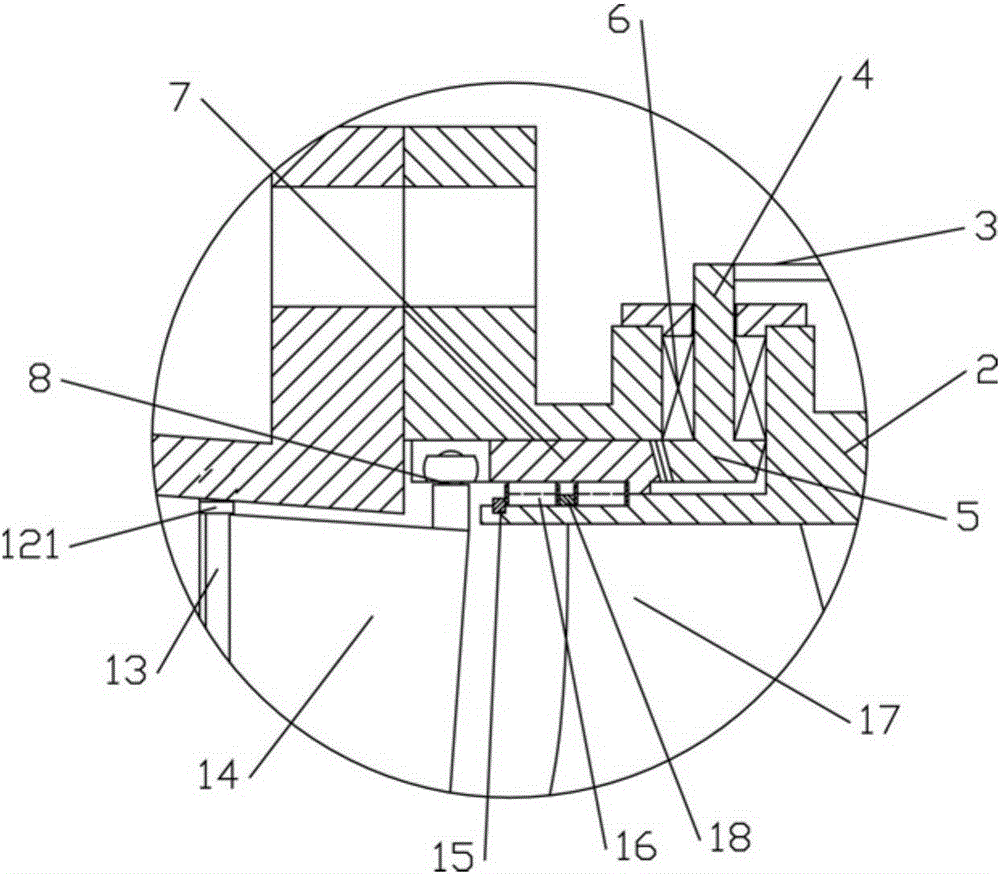

[0030] like figure 1 and 2 As shown, the tubular flow pump of the present invention includes a water inlet pipe 1, an outlet pipe 9, an impeller chamber 2, an impeller 17, a pump shaft 10, a guide vane body hub 11, five guide vane bodies and a regulating device, and a water inlet pipe 1 and a horn Formed into a round pipe, the impeller chamber 2 is a round pipe with both ends connected. Preferably, the impeller chamber 2 is formed by connecting multiple sections of round pipes through flanges. The water inlet pipe 1 is fixed at the front end of the impeller chamber 2, and the outlet pipe 9 is fixed at the rear end of the impeller chamber 2; the guide vane hub 11 is arranged at the center of the impeller chamber 2, and extends toward the water outlet pipe 9 along the axial direction of the impeller chamber 2 The pump shaft 10 is rotatably installed in the guide vane hub 11, and the impeller is fixed at the end of the pump shaft 10 near the inlet pipe 1; the fixed part 12 is fi...

Embodiment 2

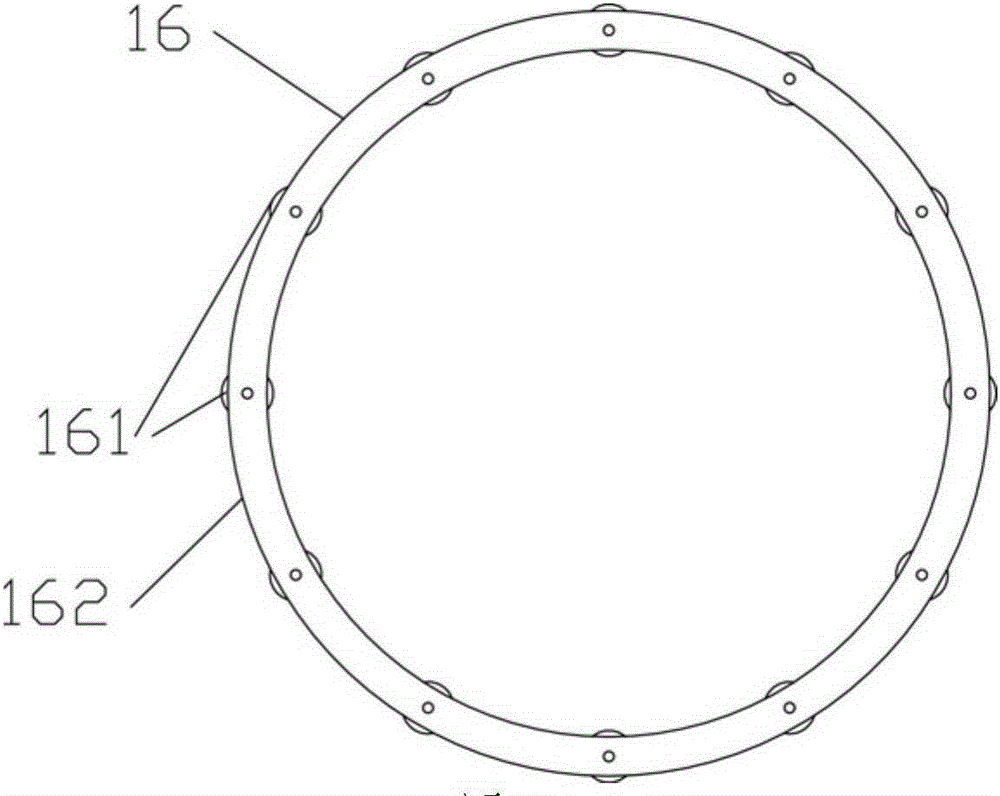

[0040] This embodiment is basically the same as Embodiment 1, except that a circle of rolling elements 16 is used in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com