Omni wheel and mobile equipment

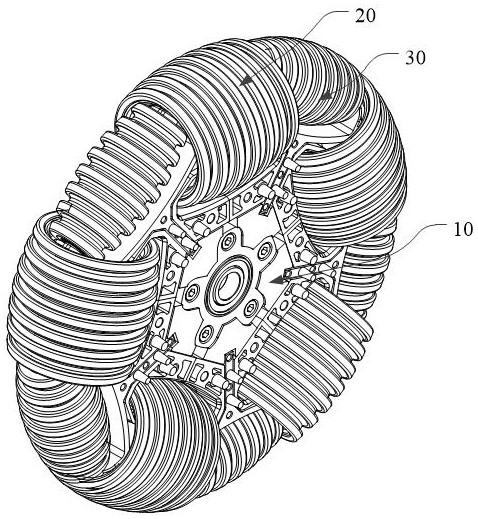

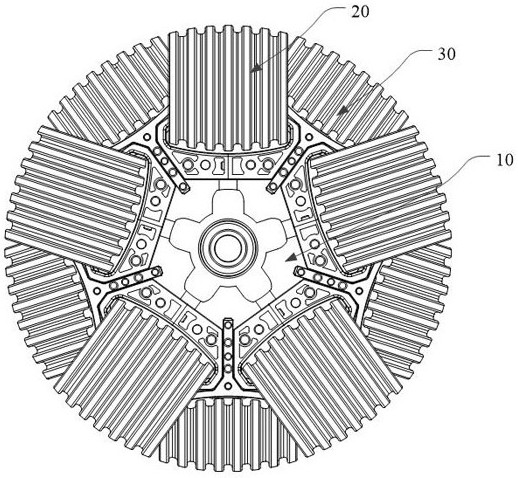

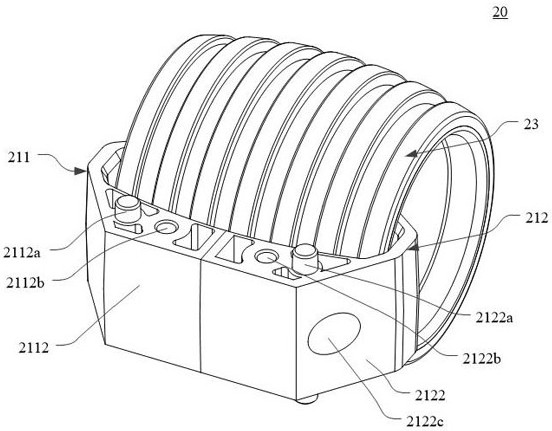

An omnidirectional wheel and roller technology, applied in the direction of wheels, vehicle parts, transportation and packaging, etc., can solve the problems of noise and vibration running stability, poor continuity of the whole wheel, loud noise and vibration, etc., and achieve compact structure and stable operation , reduce the effect of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In a related technology, two small roller brackets are used to fix the large roller. This method requires high assembly accuracy, and errors in the circumferential direction are very easy to accumulate, resulting in failure to assemble or excessive assembly clearance. Each structural part needs to be reprocessed, which affects production efficiency and increases production cost. If the assembly gap is too large, the assembled omnidirectional wheel will generate greater noise and vibration, and the running stability will be poor.

[0046] In another related technology, both the large roller and the small roller are arranged in two halves and fixed on the bracket by both sides of the bracket. Such a structural setting does not require high assembly accuracy, but there will still be noise in actual use. and vibration issues. The inventors of the present application found that the main cause of noise and vibration is the two-half structure of the large roller and the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com