Sealing system for a solenoid valve and solenoid valve

A technology of sealing system and magnetic valve, which is applied in the direction of valve operation/release device, parts in contact between valve element and valve seat, valve lift, etc., which can solve problems such as block movement and difficulty in magnetic core movement, and prevent The effect of falling off and reducing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

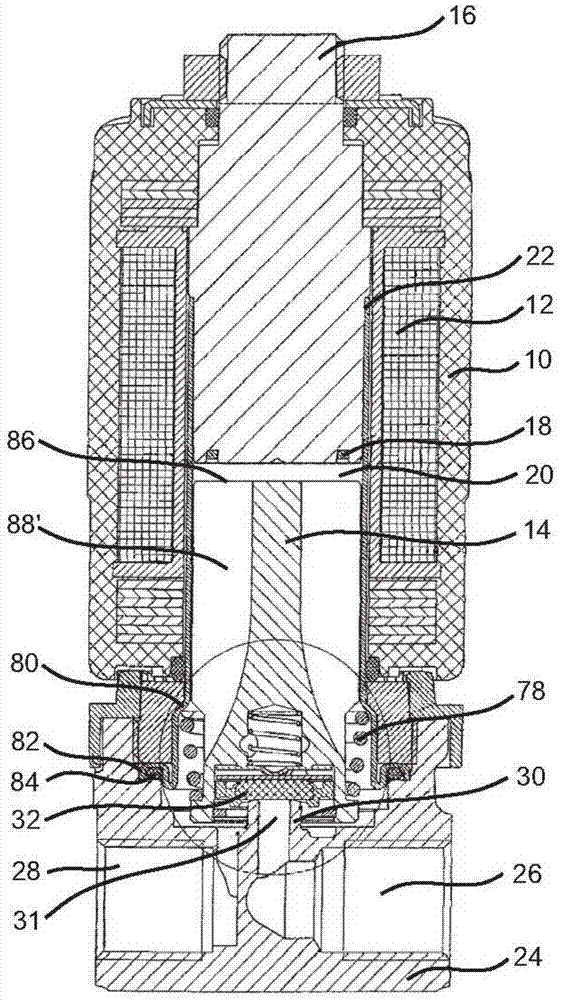

[0043] exist figure 1 shows a solenoid valve through which highly viscous oil flows and which is used to meter the oil in the fuel injector.

[0044] The solenoid valve comprises a housing 10 with an electrical coil 12 for displacing an actuating element 14 , which in the present case is designed as a magnetic core. In the following, however, for the sake of simplicity, the magnetic core is always referred to as the operating element. The operating element 14 is movable in the axial direction via the coil 12 .

[0045] In the interior of the housing 10 there is a cavity which is also partially surrounded by the coil 12 and which is closed in the axial direction by a plug 16 made of ferromagnetic material. When the solenoid valve is driven with alternating voltage, an alternating voltage ring 18 made of copper or silver is installed in the plug 16 at the end side.

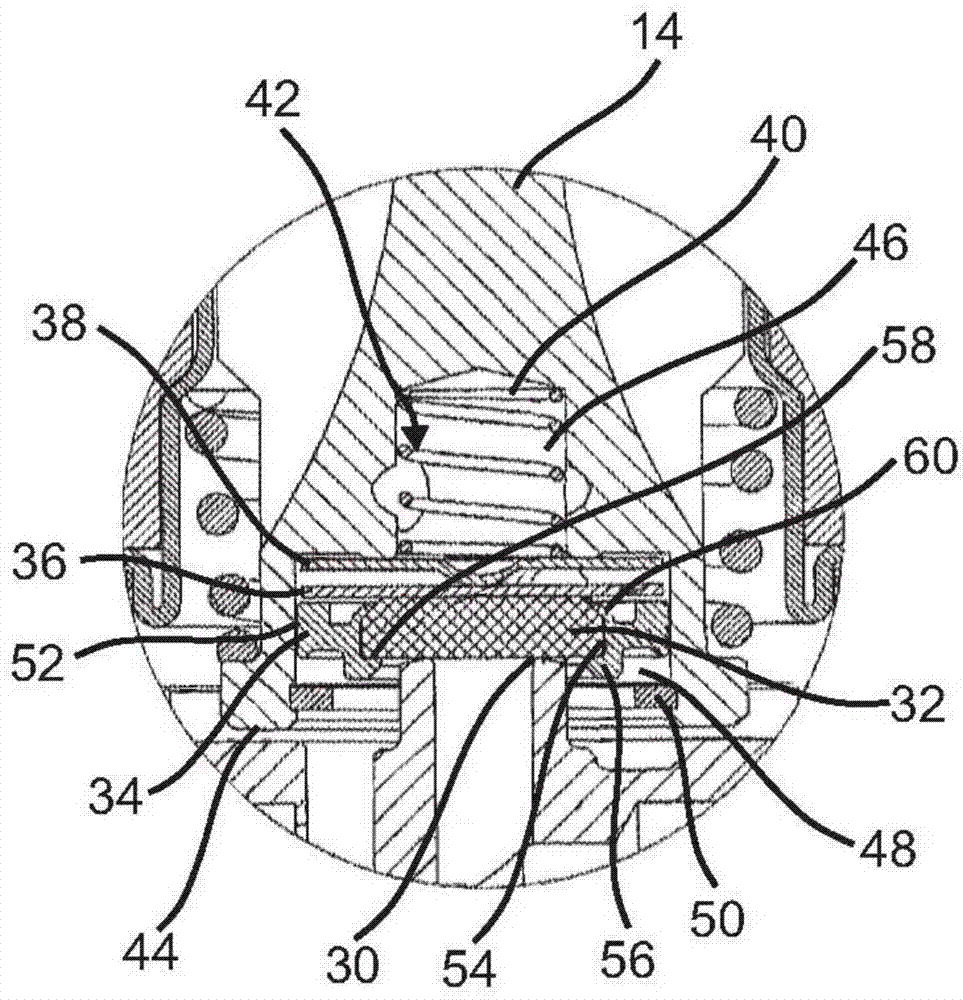

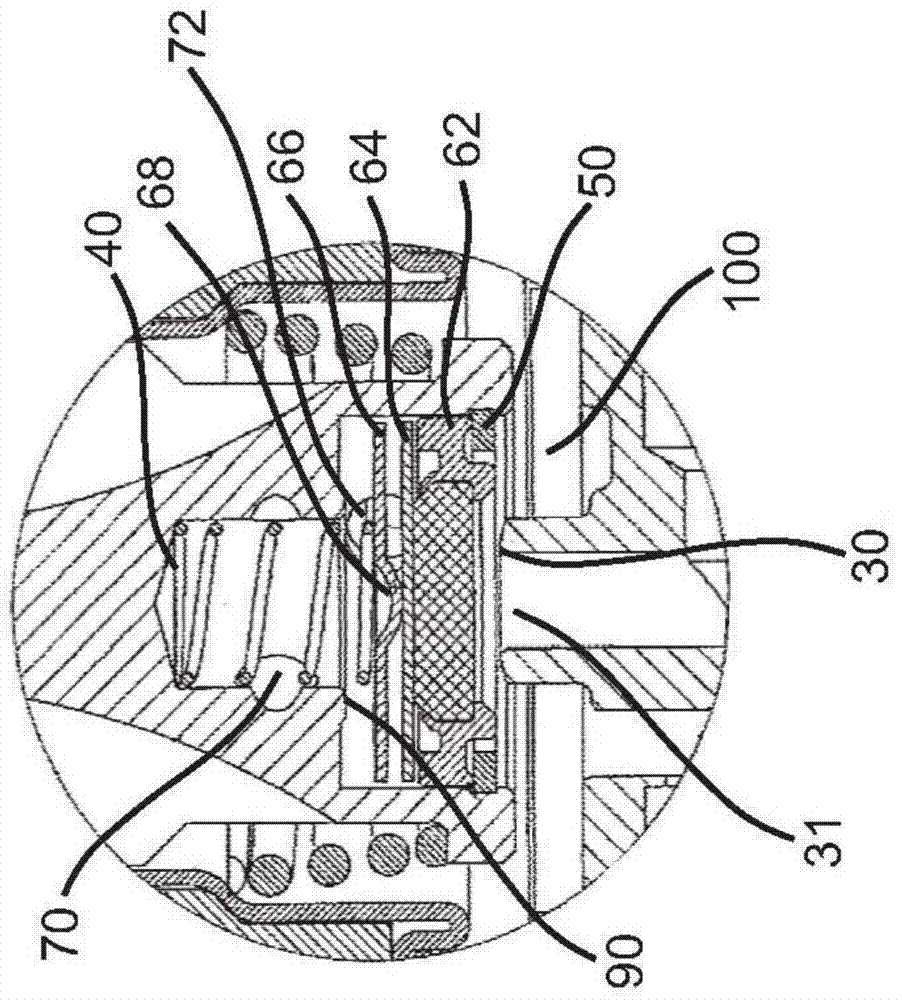

[0046] The actuating element 14 is placed in a so-called valve chamber which is partially filled by the actuatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com