The jacking system and jacking method for the prefabricated construction of pipe joints by factory method

A factory method, jacking technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve the design of cumbersome and complex jacking mechanism and jacking beam reaction force seat, inconvenient turning section pipe joints The construction and construction conditions are difficult to meet and other problems, so as to ensure the quality of the jacking construction, reduce the risk of the jacking construction, and improve the efficiency of the jacking construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

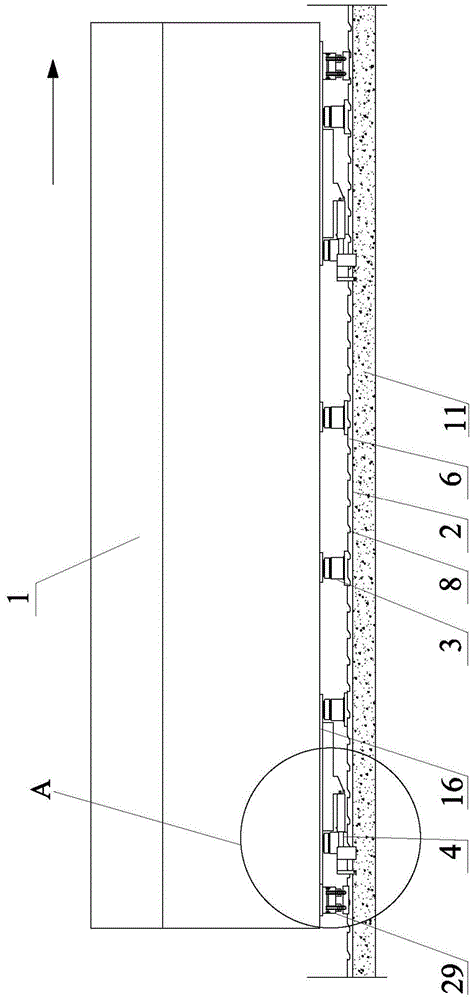

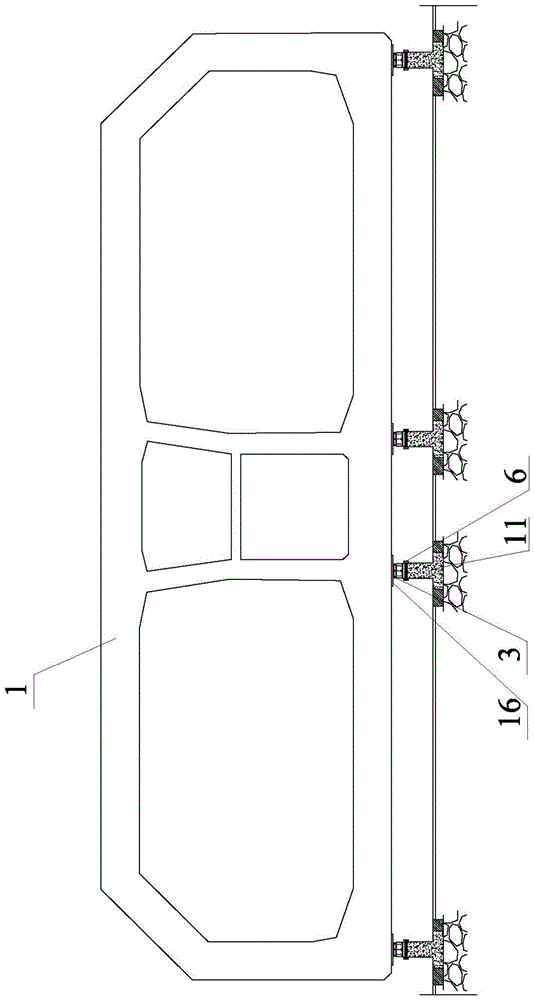

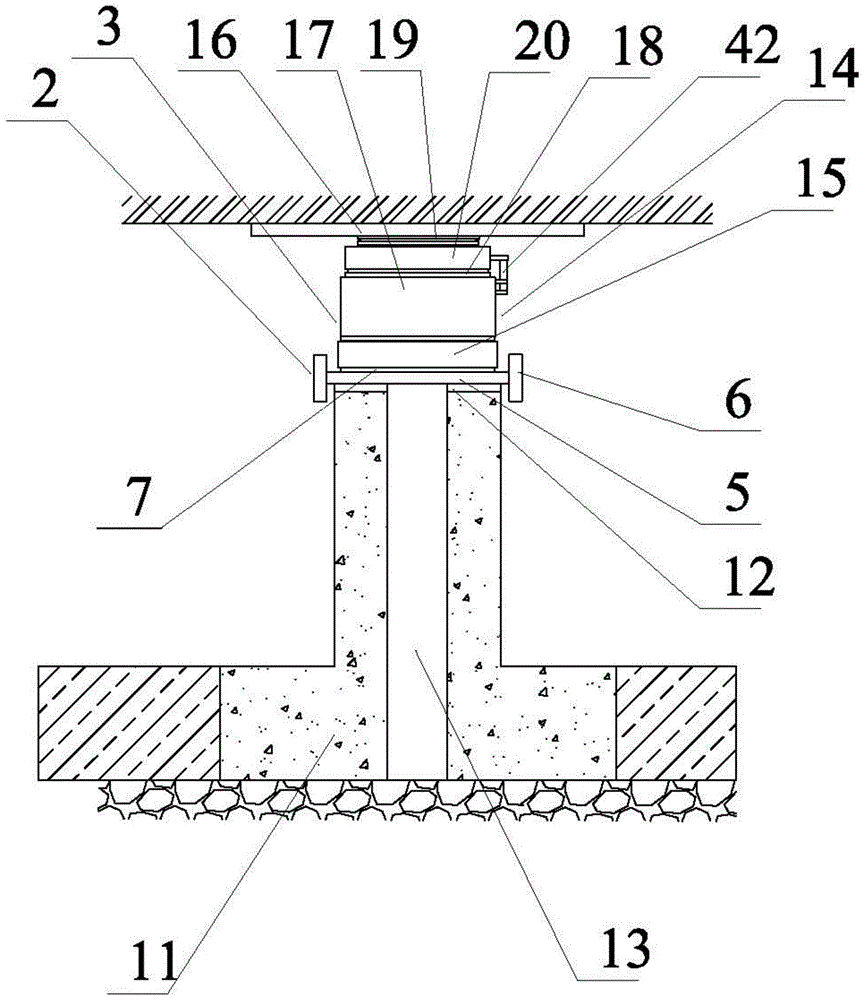

[0048] see figure 1 (The direction of the arrow is the pushing direction of the pipe joint), figure 2 , image 3 Figure 4 , Figure 5 , Figure 6As shown, the jacking system for the prefabricated construction of the pipe joint in the factory method of the present invention includes a plurality of slide rails 2 arranged in parallel for realizing the horizontal displacement of the pipe joint 1, and a plurality of sliding rails 2 for the overall support of the pipe joint. The supporting device 3, a plurality of pushing devices 4 for pushing the pipe joints, and a general control device for overall control of the pushing system work; the slide rail is arranged under the pipe joints and arranged along the length direction of the pipe joints The support device is correspondingly arranged in the slide rail, the upper end of the support device is fixedly connected to the bottom end of the pipe joint, the lower end is slidably connected to the slide rail, and arranged in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com