Rolling bearing-rotor system damage vibration response quantitative calculation method

A vibration response and rolling bearing technology, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of few coupling systems, inaccurate simulation results, and inability to quantitatively simulate the influence of the size of the damage area, and achieve the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

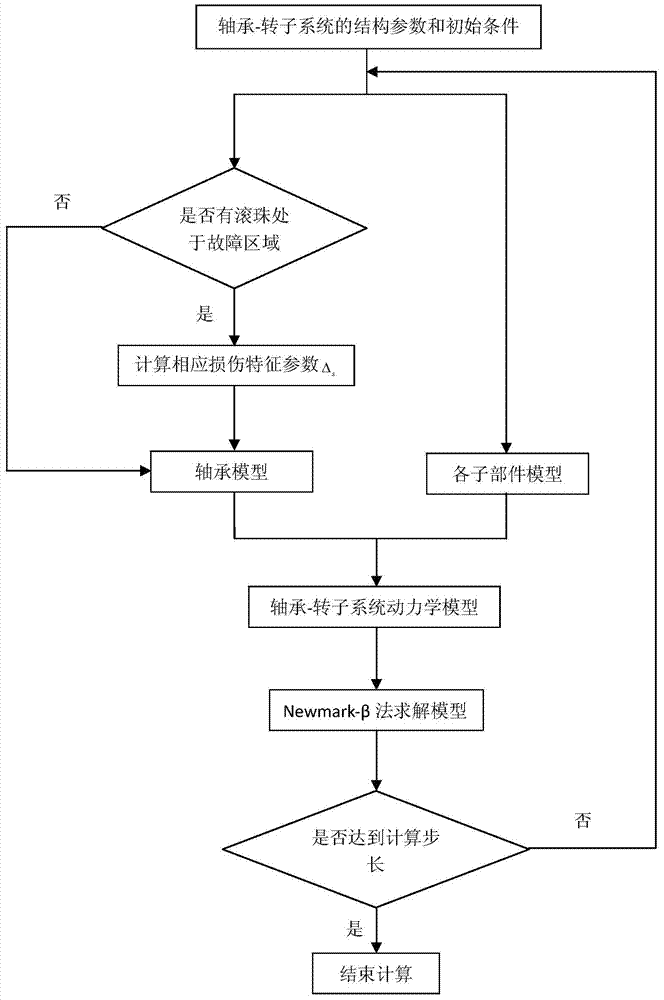

[0039] see figure 1 As shown, the present invention provides a method for quantitatively calculating the damage vibration response of a rolling bearing-rotor system, comprising the following steps:

[0040] 1) Obtain the structural parameters and initial parameters of the bearing-rotor system, the structural parameters include bearing parameters, geometric dimensions of sub-components, material property parameters and damage characteristic parameters; the initial parameters include the external force vector F of the bearing-rotor system, the rotor speed Ω;

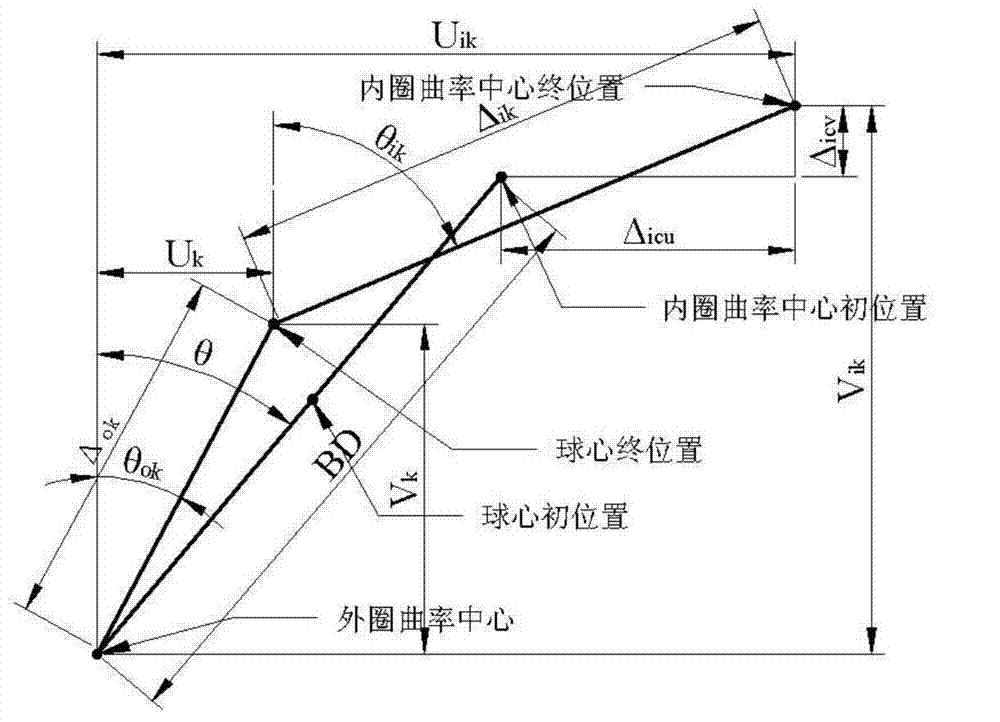

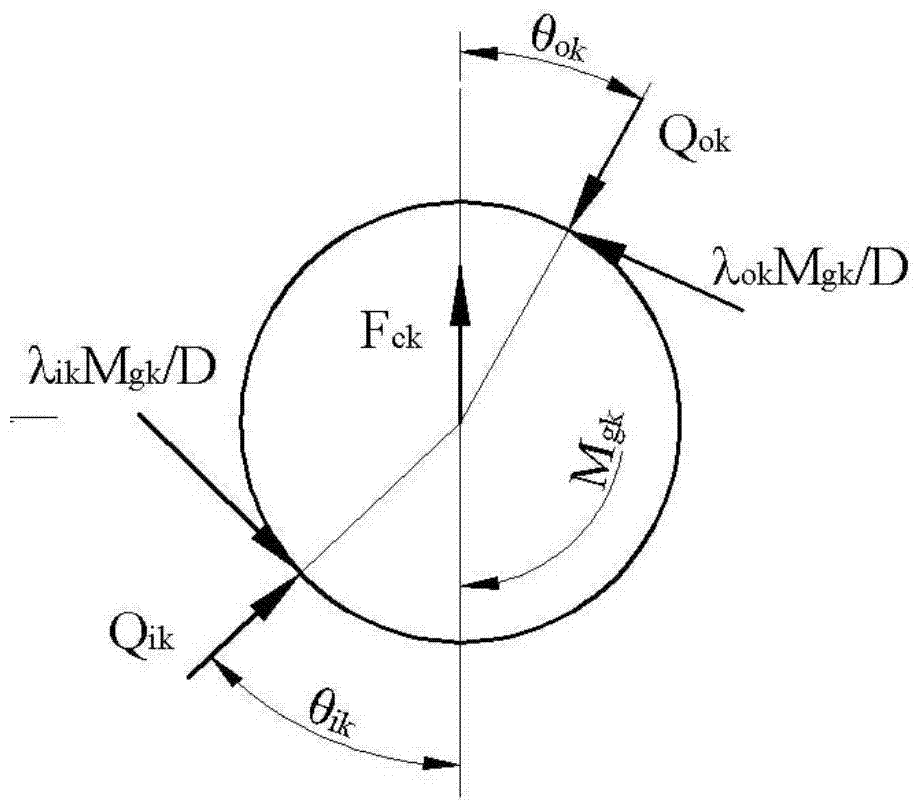

[0041] 2) Establish a five-degree-of-freedom bearing model based on the bearing parameters, and obtain the bearing stiffness matrix K of the bearing-rotor system B ;According to the geometric dimensions and material characteristic parameters of the sub-components, a finite element model is established to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com